The impact of road-tire wear: a hidden source of airborne microplastics and black carbon

Recent studies conducted in the Colorado Rocky Mountains reveal that tire particles, laden with nano-sized carbon black, are being deposited on high-altitude snow, contributing to accelerated melting and atmospheric warming. Analysis by Emissions Analytics identified organic compounds in these particles that match those found in road tires, highlighting their widespread environmental presence.

A major source for airborne microplastic particles is road-tire wear. Microscopy and chemical analyses of wind-blown particles on dirty, high-elevation (2865-3690 m) snow surfaces in the Colorado Rocky Mountains revealed the presence of black carbonaceous substances intimately mixed with microplastics, particles interpreted as tire matter.

Identical and similar particles occur in shredded tires and in samples collected from road surfaces. The black substance responsible for the black color of all tire particles is nano-size carbon black, a tire additive that homogeneously permeates tire polymers and other additives and that strongly absorbs solar radiation .

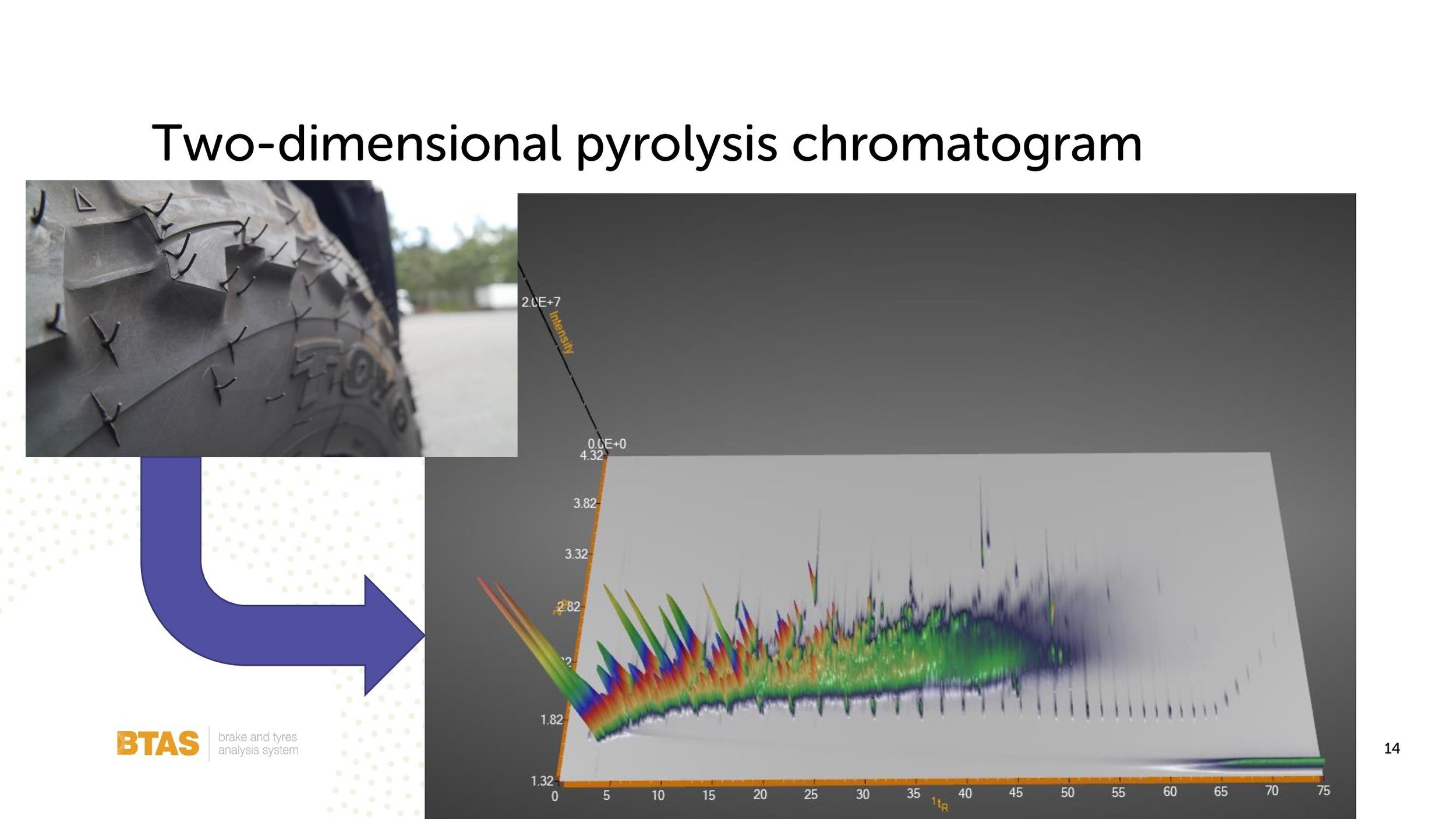

The key to documentation of worn tire matter was the identification in two-dimensional gas chromatography by Emissions Analytics of many organic compounds in snow common to those in road tires. The mass of black carbonaceous particles produced by road-tire wear may be estimated by multiplying measured mass of eroded tire-per-distance traveled by vehicular distances. The eroded tire mass from moving vehicles used for these estimates was measured by Emissions Analytics.

Under assumptions of amounts of tire-wear particles emitted to the atmosphere, the mass proportion of atmospheric black carbonaceous matter from annual road-tire wear might be as much as about 10-30% of atmospheric black carbon, such as soot from vehicle exhaust and domestic cooking. Black particles from road-tire wear may thus be an important component that contributes to melting of snow and ice as well as to warming the atmosphere. The potential toxicity of organic compounds in black-tire matter is another concern for the health of organisms in mountain ecosystems. A revised estimate for the annual mass of eroded tires globally is 6550 kilotonnes.

Citation:

Reynolds, R. L., Molden, N., Kokaly, R. F., Lowers, H., Breit, G. N., Goldstein, H. L., Williams, E. K., Lawrence, C. R., & Derry, J. (2024). Microplastic and Associated Black Particles from Road-tire Wear: Implications for Radiative Effects across the Cryosphere and in the Atmosphere. Journal of Geophysical Research: Atmospheres, 129, e2024JD041116, https://doi.org/10.1029/2024JD041116

Presentation: Emissions Analytics Tire Technology Expo Presentation 20 March 2024

Our CEO & Founder, Nick Molden recently spoke at the Automotive Tire Technology 2024.

CEO & Founder, Nick Molden spoke at the Tire Technology 2024.

Why you should be interested in tyres

A surprisingly compelling subject

Dinner table, or social media, conversation may centre on arguments over which football team deserves to win the league, or whether the Mustang or Camaro is better, but the common feature of such polemics is that they represent simple and interesting questions. The topic of tyres, however, and if you dare raise it, may stun your companions into silence. Tyres are not simple and interesting. They are complex and boring – at least on the outside.

A surprisingly compelling subject

Dinner table, or social media, conversation may centre on arguments over which football team deserves to win the league, or whether the Mustang or Camaro is better, but the common feature of such polemics is that they represent simple and interesting questions. The topic of tyres, however, and if you dare raise it, may stun your companions into silence. Tyres are not simple and interesting. They are complex and boring – at least on the outside. Delve a little deeper, and they become items of sophistication and almost wonder. Mysterious, near-anonymous products that power many parts of the modern economy and society. Omnipresent, but no ingredients label. Emissions Analytics thinks you should be interested in tyres, and you should talk about them at dinner tonight.

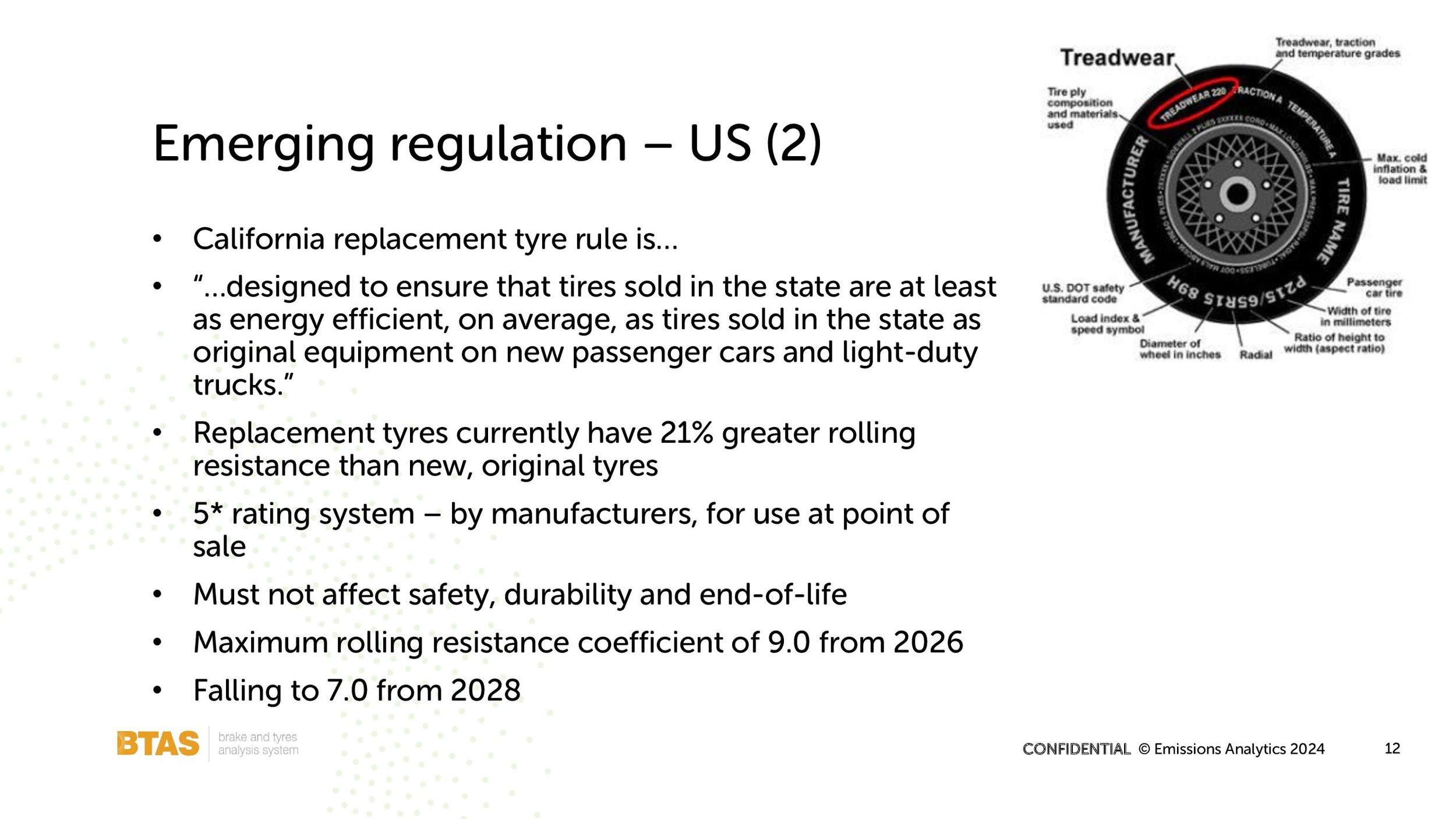

But if you can’t face that quite yet, you should first of all attend our newly launched conferences in Europe and US on tyre emissions and sustainability. Many excellent events already exist in this sector, but the common factor is that they look at tyres from the inside out: from the industry perspective in how to make better tyres. Environmental concerns are now forcing us to look from the outside in: how can we mitigate the effects of tyres from their manufacture and usage. Regulation is coming – and has already arrived in California.

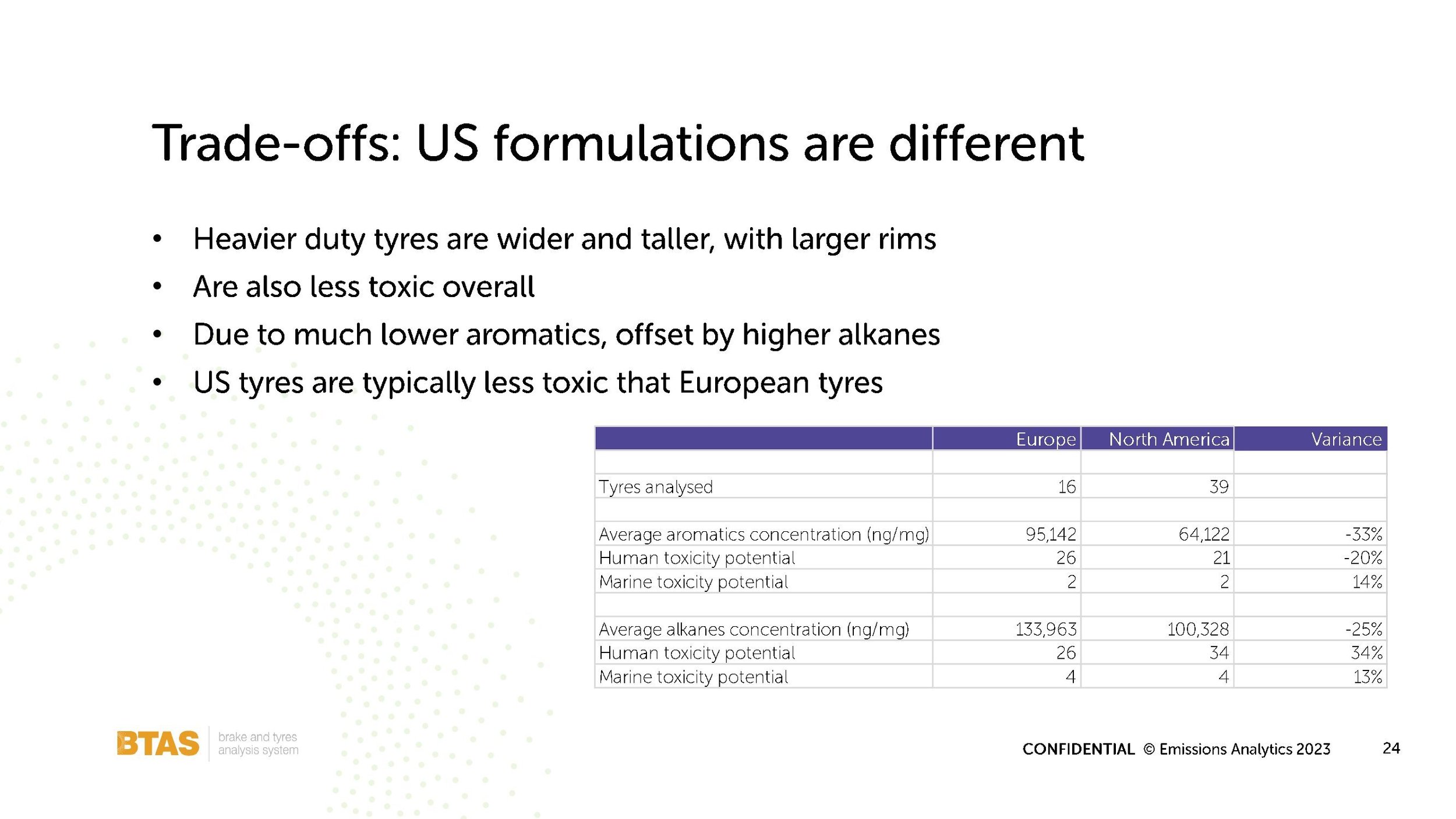

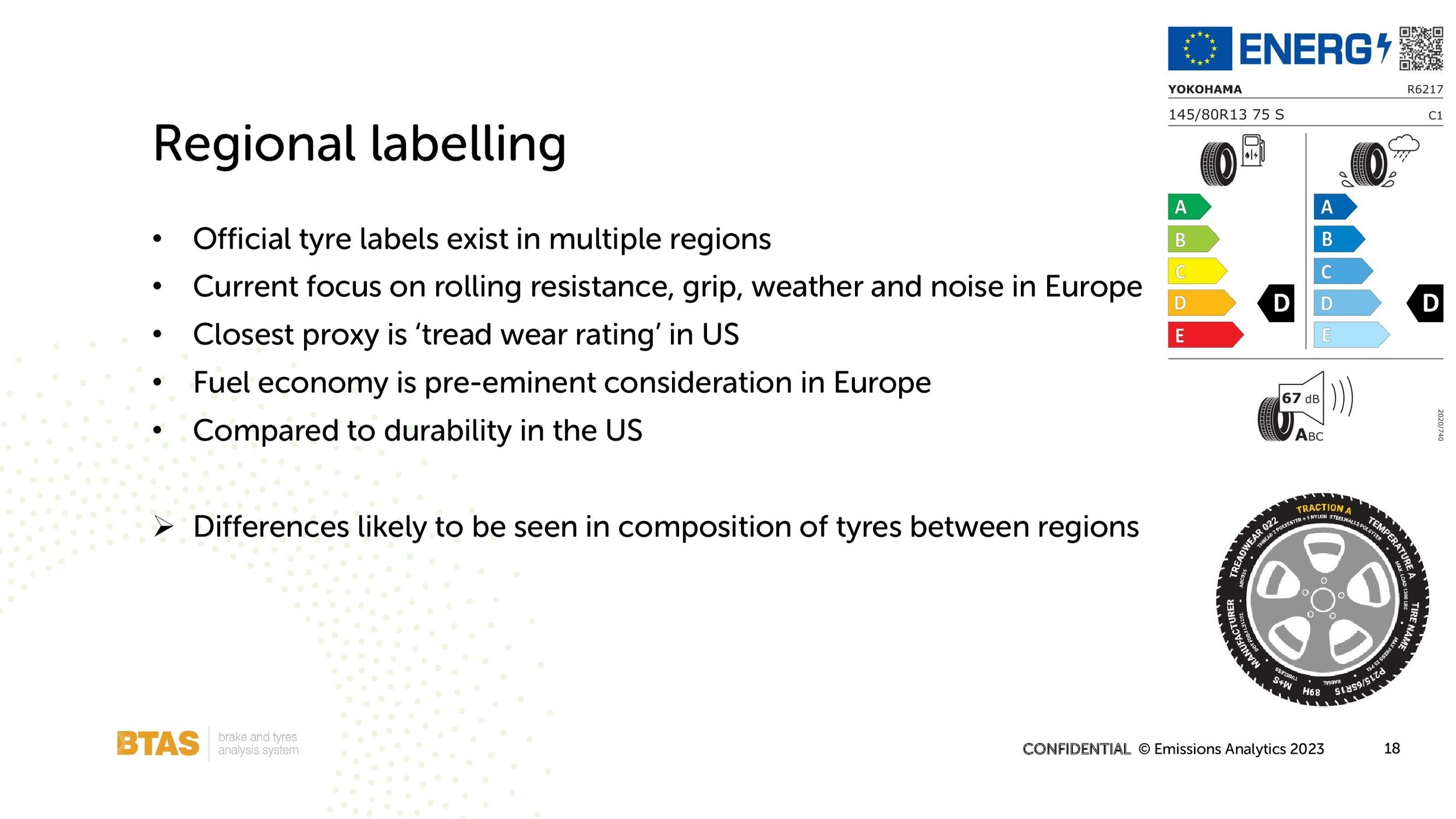

The tyre industry is highly sophisticated yet somewhat secretive. Challenging problems are solved quietly without disclosing the nature of the solution. European tyres have achieved combinations of grip, noise and rolling resistance to meet the requirements and demands and of the market, while US tyres have remained simpler in formulation as durability has remained the over-riding preference. Unlike vehicle manufacturers, which exist in spotlight of regulation and consumer interest, tyre manufacturers just get on with it. Witness the invention of synthetic rubber in the Second World War, which has defined the industry ever since.

The big challenges today are often environmental. How to makes tyres with more sustainable materials – however they be defined? How to reduce microplastic and volatile organic emissions in use? This is not a problem created by heavy battery electric vehicles, but the near elimination of tailpipe pollutant emissions from modern vehicles has brought it into focus – many vehicles now emit 90% below emissions standards for nitrogen oxides, carbon monoxide, and particles. Although distance-specific tyre mass emissions may be in long-term, like-for-like decline, this is increasingly offset by more vehicles on the road, more miles driven, heavier vehicles and more torque. Our testing suggests 26% tyre wear emissions from pure battery vehicles compared to equivalent full hybrids.

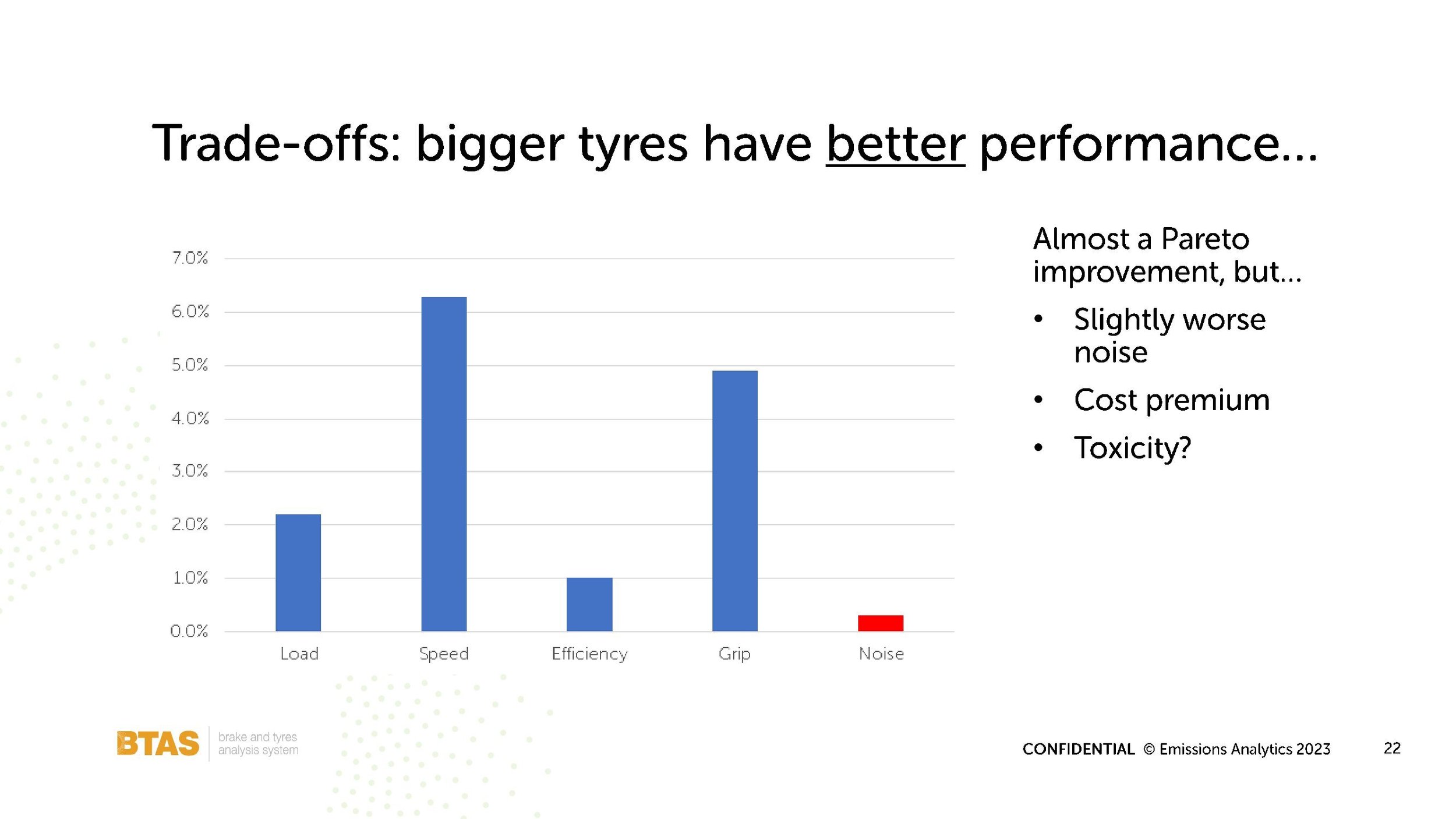

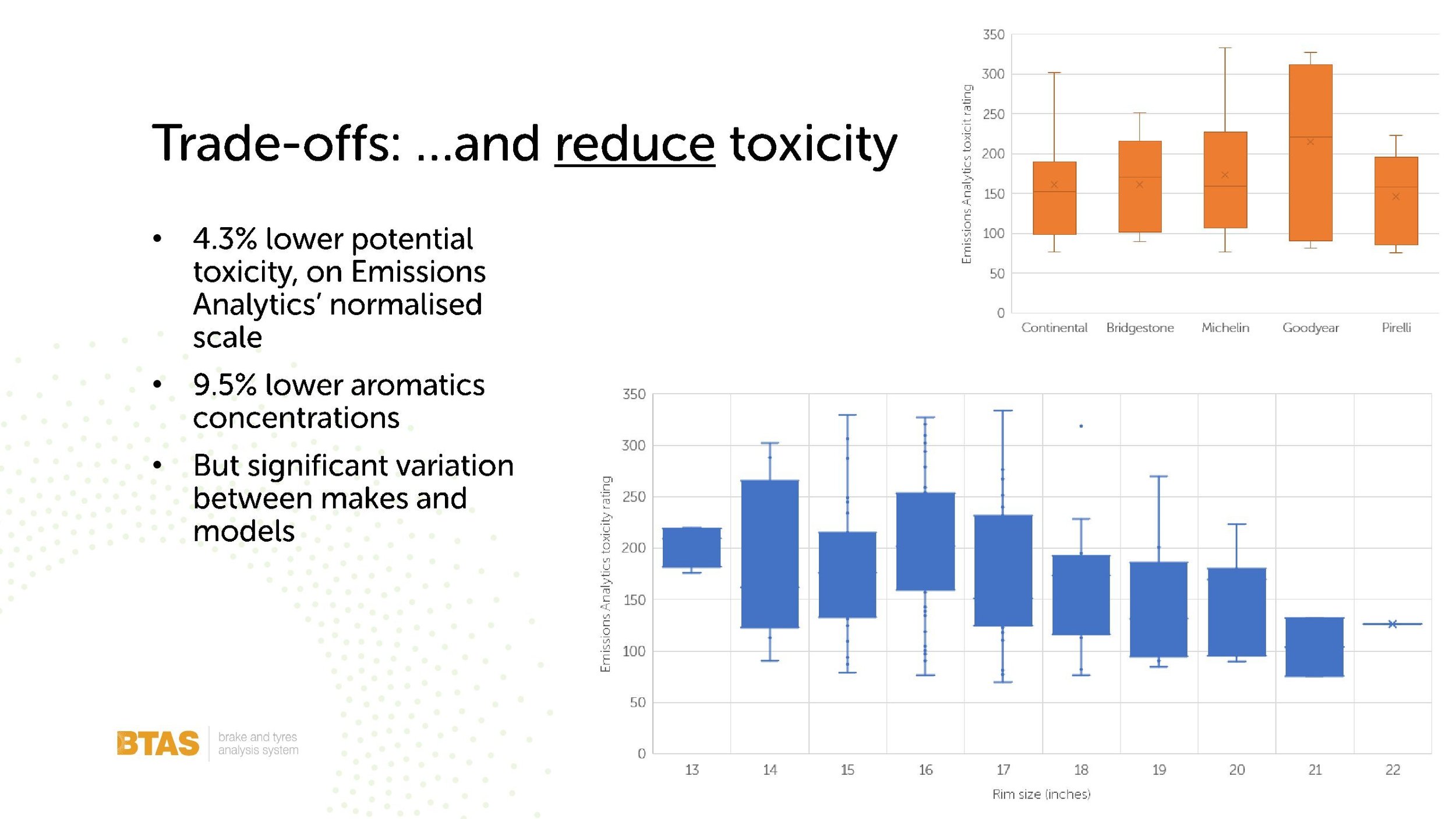

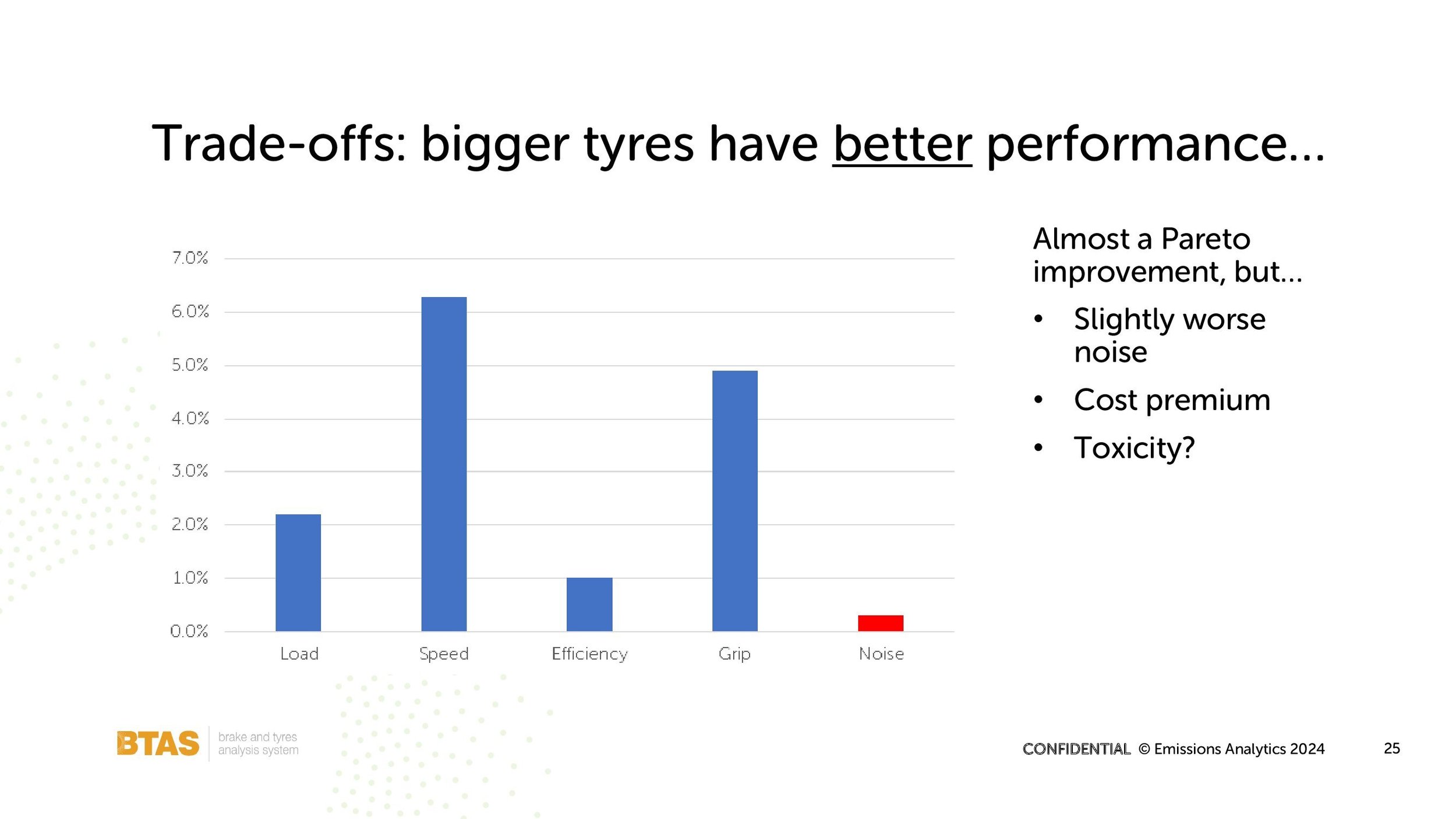

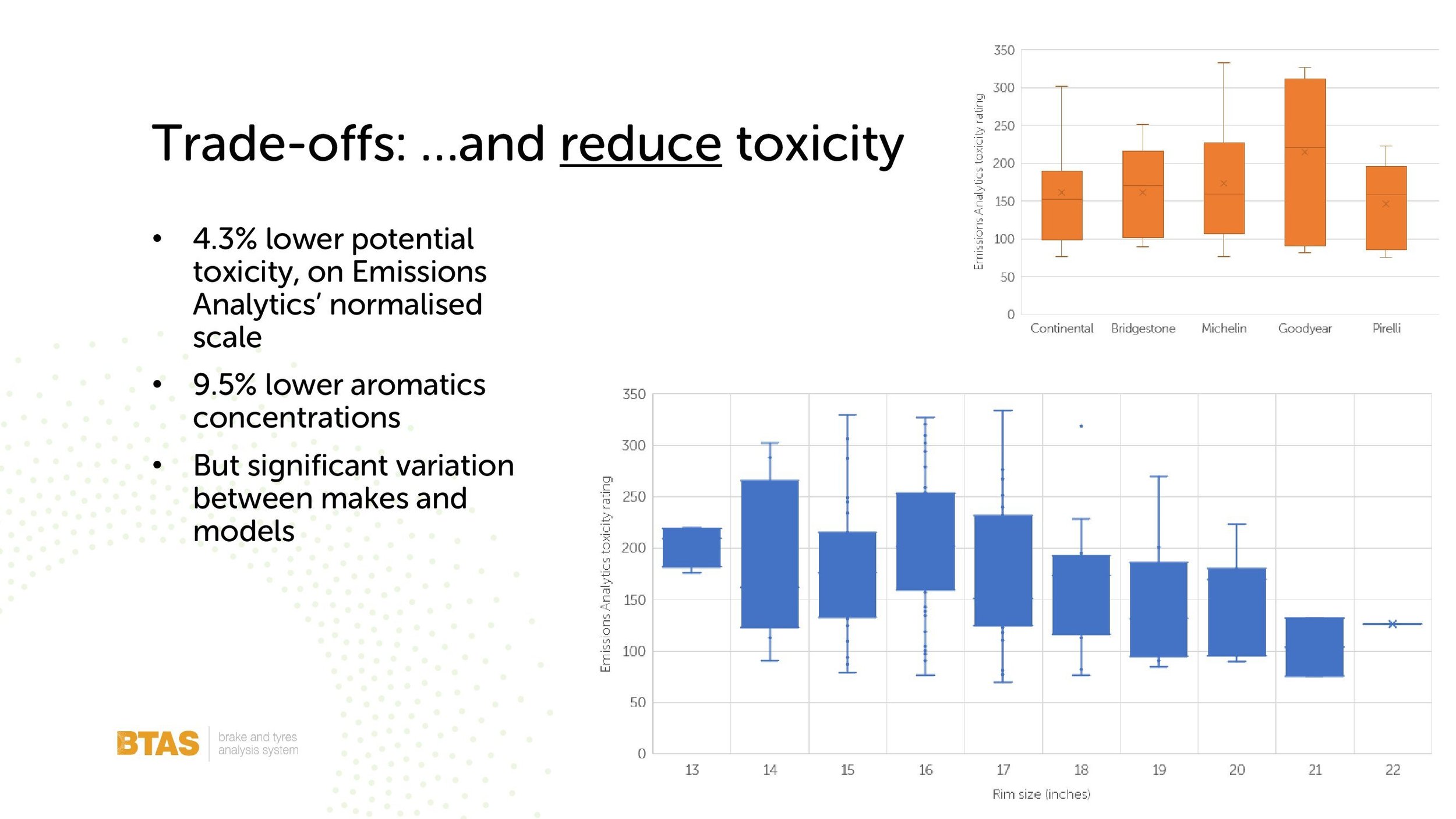

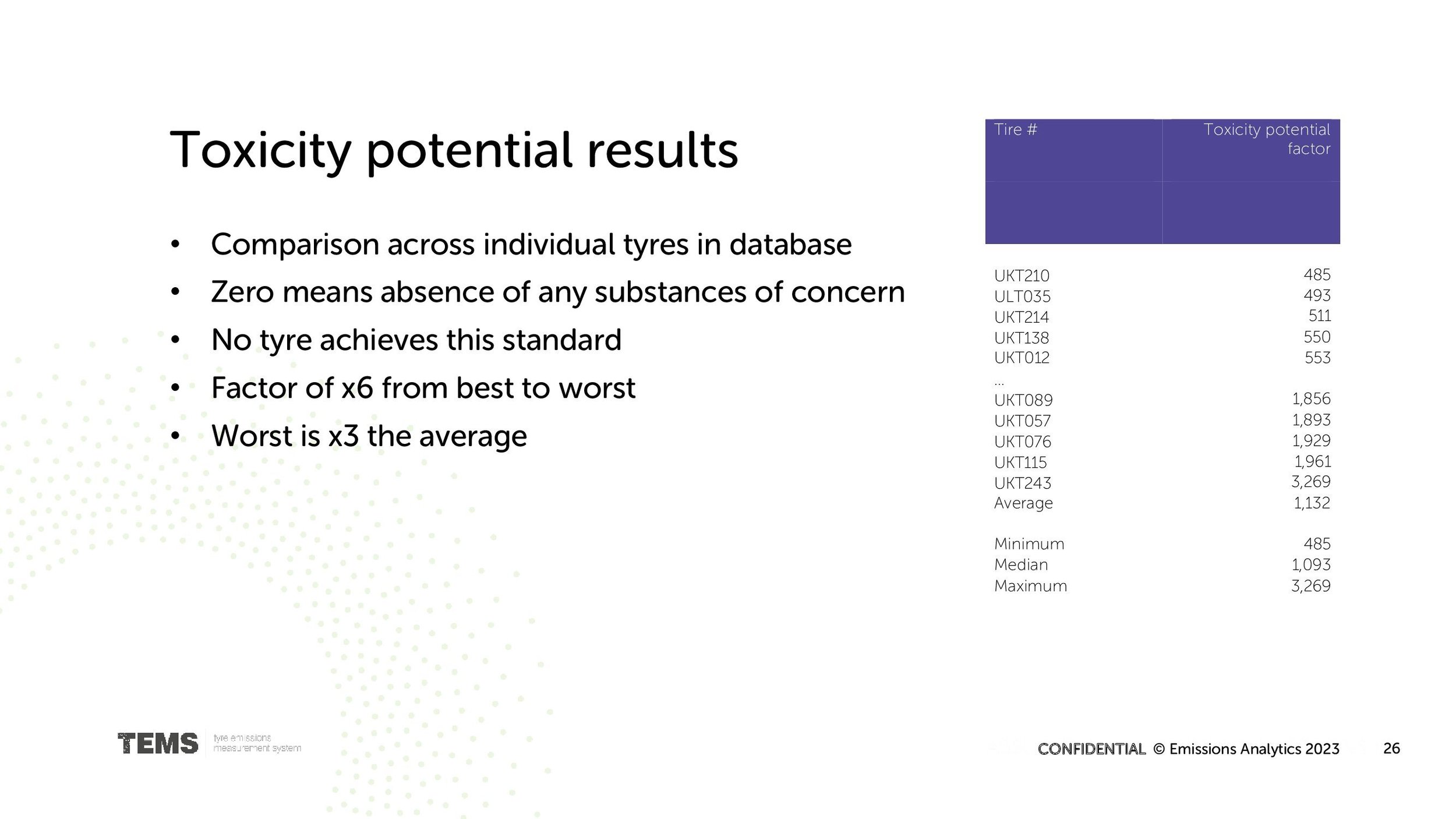

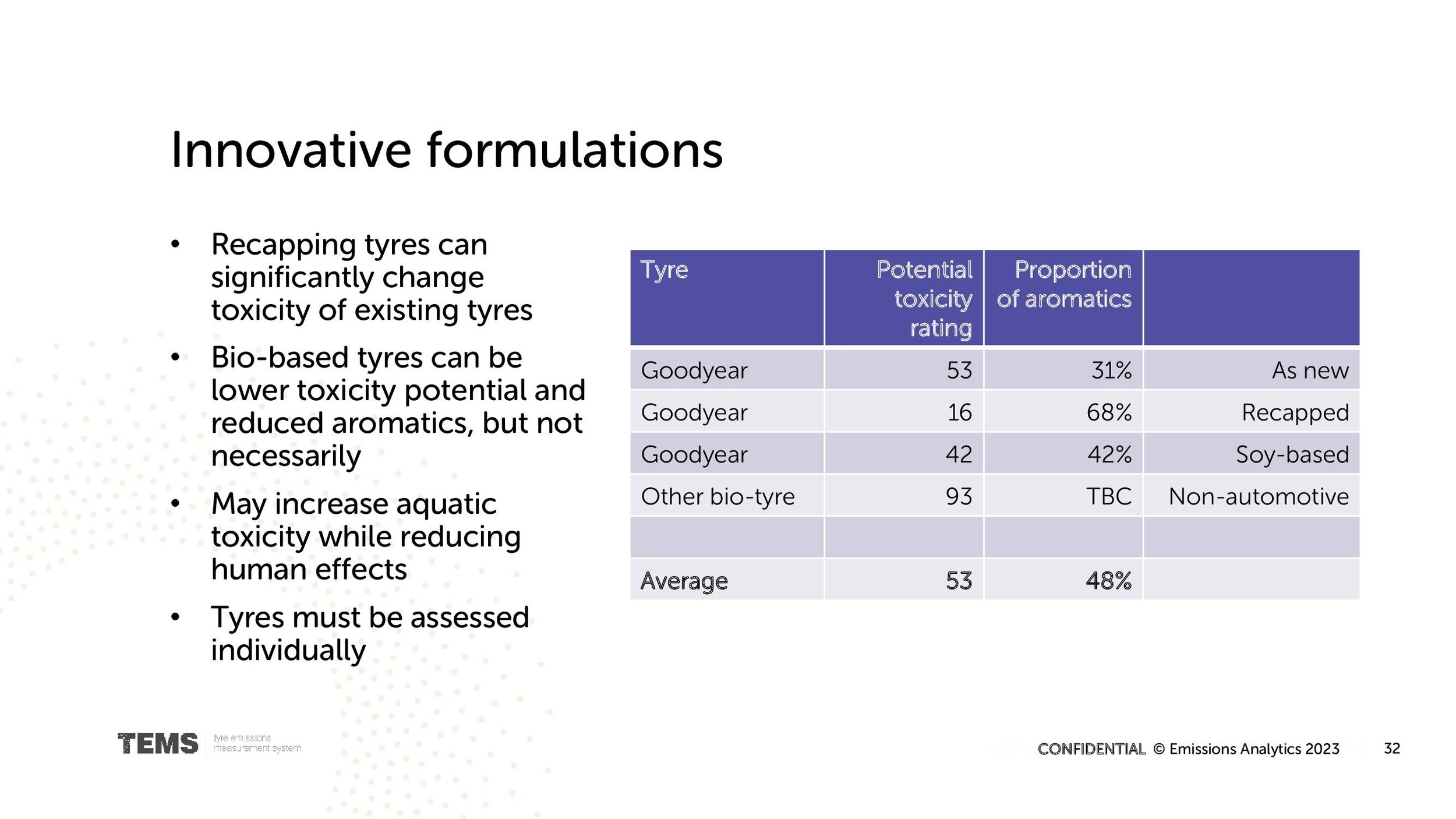

To counter this trend, new tyre formulations are being quietly brought to market to handle this heavier and ever more demanding vehicles. The immediate concern that ‘eco’ tyres could deliver such performance at the price of being more environmentally toxic appears to not to be simplistically true from Emissions Analytics’ latest testing. On our toxicity potential metric, these eco tyres may in fact be a quarter or more less toxic than standard tyres. This could to a great extent neutralise the increased mass wear rates, but with two caveats, First, it requires detailed analytical testing to verify this. Second, these eco tyres come at a financial price to the consumer.

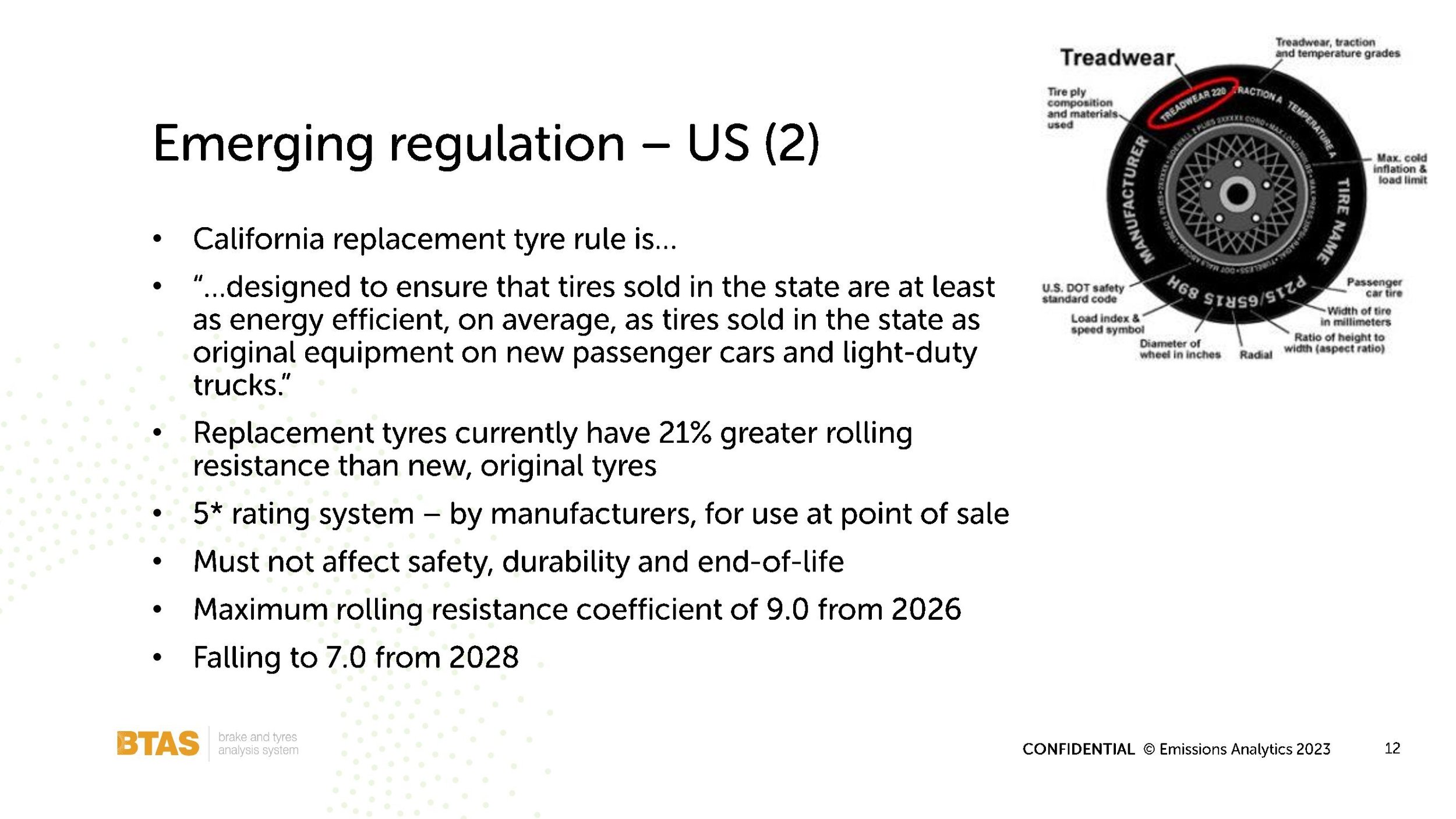

While the focus in such matters of regulation tend to start with new products, it may be regulations about replacement tyres that will have a greater bearing on the combined environmental of tyres. A brand-new battery vehicle equipped with the latest, most sophisticated eco tyres limit emissions, only for that good work to be undone when they are ultimately replaced by cheaper, less sophisticated alternatives. A private saving for the vehicle owner may create a public cost in pollution.

Seeking to address these questions, our first event will take place in Prague on 28-29 February 2024, and further details can be found here. Two months later, on 24-25 April, we will pick up the discussion in Southern California, details here. We encourage you all to apply to attend and submit abstracts for presentations.

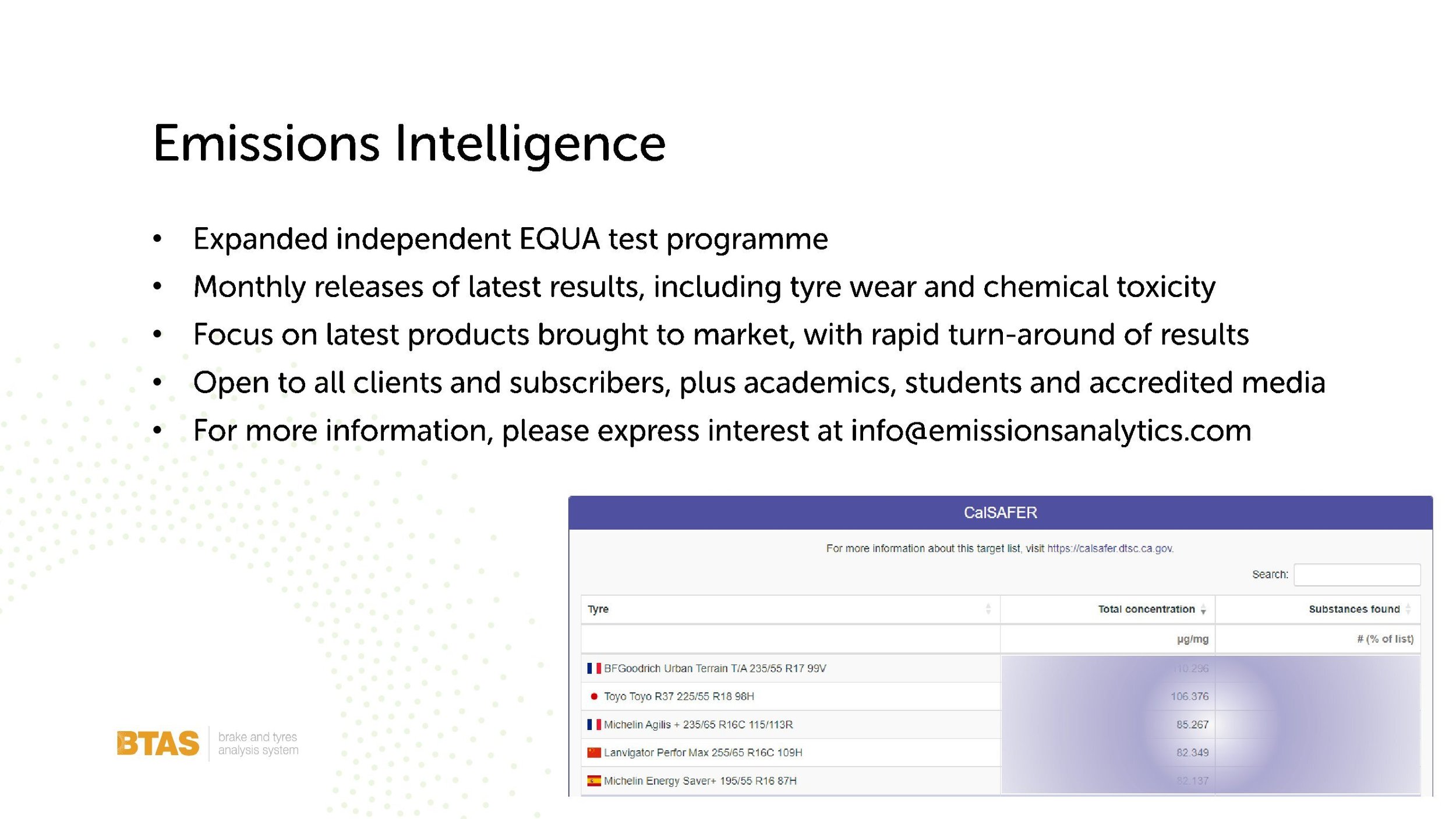

Alongside this, we will be publishing regular, detailed results of Emissions Analytics’ tyre wear and chemical composition testing, along with our monthly newsletter, via our Emissions Intelligence subscription – please contact us to find out more.

Together, these new initiatives from Emissions Analytics are engaging with society and industry to bring about an understanding and appreciation of the sheer cleverness and importance of tyres, and how vital the right choices are for the environment. Consumers want to do the right thing, but the choice of tyres for many is currently too boring and complex. Let’s change this. Let's start the conversation.

Webinar: Tyre emissions from the latest electric vehicles

Our CEO & Founder, Nick Molden presented a webinar on the tyre emissions from the latest electric vehicles on 19th September 2023. The world is on a path to electrifying everything that moves, primarily driven by the desire to decarbonise. But no vehicle is zero emission, and the latest emissions regulations in Europe, the US and beyond are now starting to incorporate non-exhaust emissions.

Our CEO & Founder, Nick Molden presented a webinar on the tyre emissions from the latest electric vehicles on 19th September 2023.

To watch the webinar and download the presentation please see below.

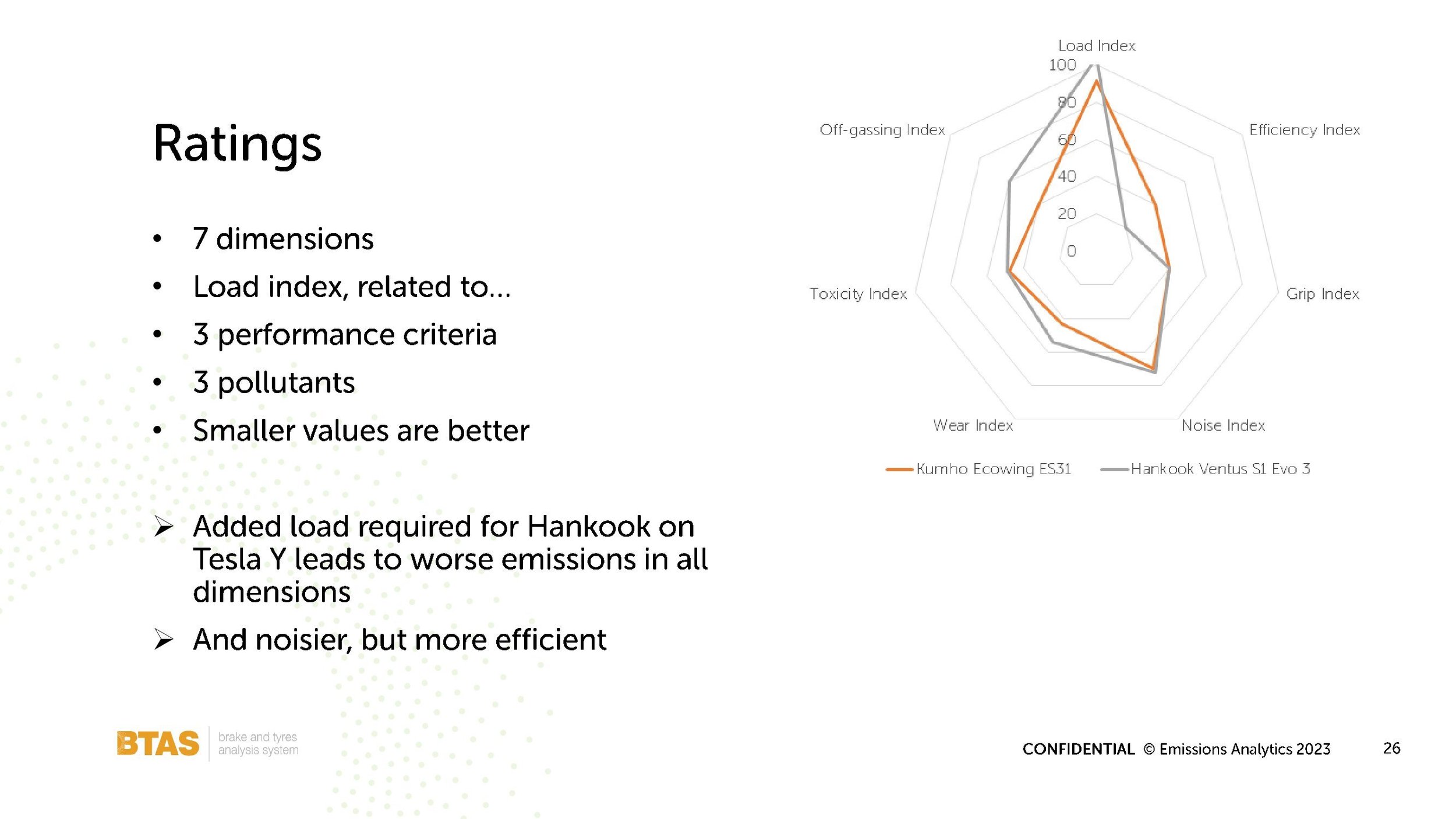

The world is on a path to electrifying everything that moves, primarily driven by the desire to decarbonise. But no vehicle is zero emission, and the latest emissions regulations in Europe, the US and beyond are now starting to incorporate non-exhaust emissions. The task is a major one, though, as changes in other regulations and tastes are leading to ever-heavier vehicles, which is likely to increase tyre emissions. What is less well understood is the chemical formulations used in specialist 'EV tyres', and whether they are potentially more or less toxic that standard tyres. This webinar will share the latest chemical profiling results from our EQUA test programme, to show the key trends.

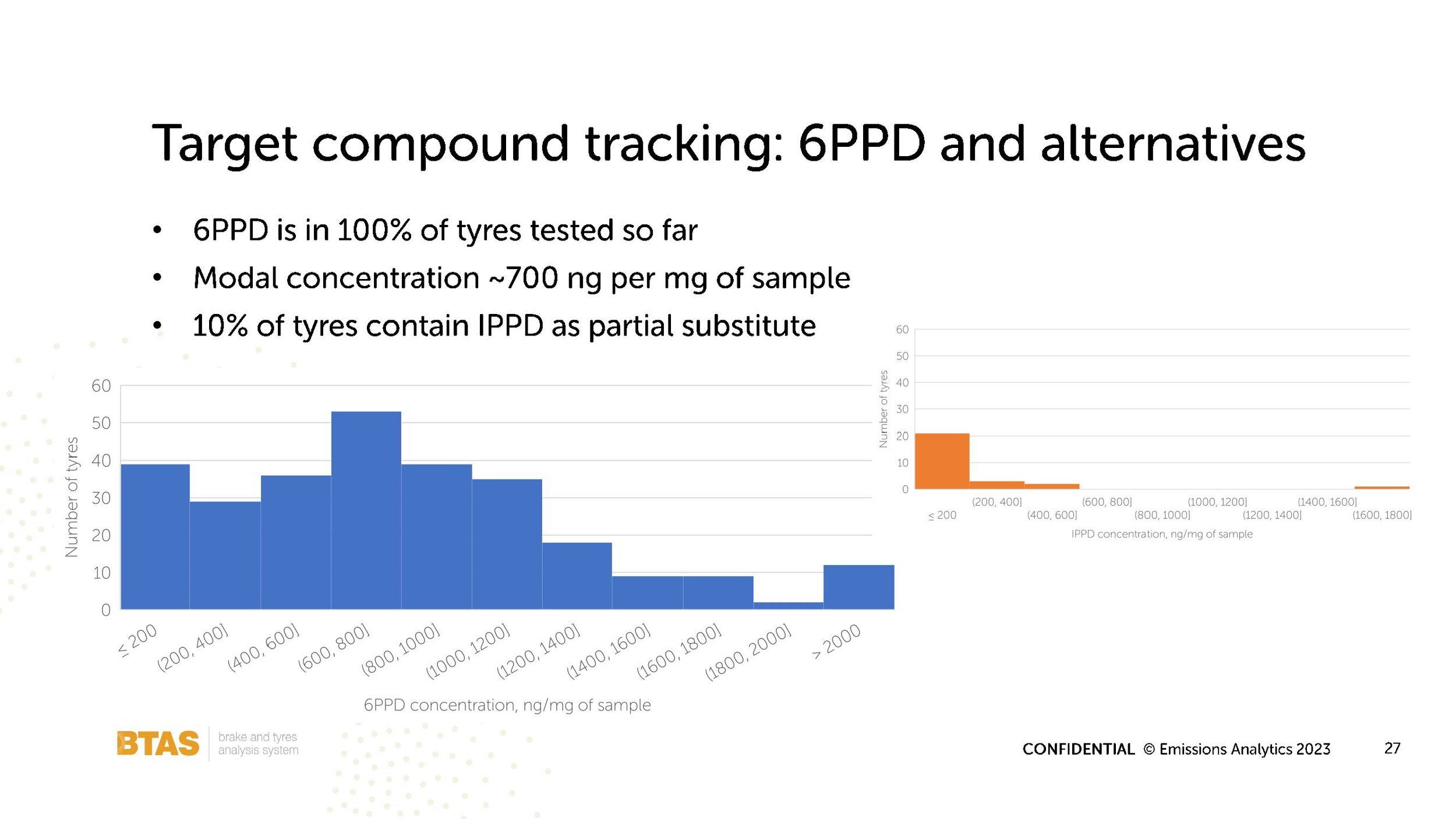

This is particularly relevant in the light of the California Environmental Protection Agency’s new rule on chemical composition, aiming to reduce the use of the toxic 6PPD preservative. We will show the extent to which alternatives are already being used. We will also consider the progress the European Union is making on its Euro 7 regulation for tyres. Current proposals for a measurement method fromt he Task Force on Tyre Abrasion will be reviewed in the light of our real-world wear rate testing. How efficient and effective will the proposed method be, and what might an optimal initial limit value look like? This testing fits within Emissions Analytics’ expanded EQUA test programme, which includes regulated and unregulated tailpipe emissions and vehicle interior air quality. Watch out for future webinars on these topic, and do subscribe to Emissions Analytics' newsletter to find out about priority access.

Emissions Analytics and the University of Portsmouth collaborate on the study to investigate impact of toxic tyre chemicals in UK waters

Emissions Analytics is thrilled to be featured in a groundbreaking news article by the University of Portsmouth. The article, titled "Study to Investigate Impact of Toxic Tyre Chemicals in UK Waters," sheds light on a crucial research endeavor that aims to understand the environmental consequences of tyre chemical pollutants.

Emissions Analytics is thrilled to be featured in a groundbreaking news article by the University of Portsmouth. The article, titled "Study to Investigate Impact of Toxic Tyre Chemicals in UK Waters," sheds light on a crucial research endeavor that aims to understand the environmental consequences of tyre chemical pollutants.

To learn more about this groundbreaking study and the role of Emissions Analytics, we invite you to read the full article on the University of Portsmouth's website. Click here to access the article and delve into the research that is shaping the future of environmental sustainability.

Open letter: Regulating pollutants from tyre emissions

An important and groundbreaking part of the proposed Euro 7 regulation involves setting a limit value for tyre wear emissions. This is particularly important as vehicles continue to become heavier, not least with the growing sales of battery electric vehicles.

To whom it may concern:

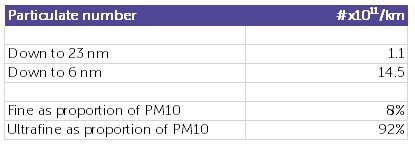

An important and groundbreaking part of the proposed Euro 7 regulation involves setting a limit value for tyre wear emissions. This is particularly important as vehicles continue to become heavier, not least with the growing sales of battery electric vehicles. However, the current proposal covers only the total mass of emissions and, therefore, ignores both ultrafine nanoparticles and chemicals released from the tyres. Without changes, it is likely that tyres will be re-engineered to deliver lower emissions of larger particles but potentially at the cost of the release of more invisible nanoparticles and potentially toxic chemicals.

Therefore, we would call on the European regulators to initiate work as soon as possible on a second phase to Euro 7 tyre emissions that would expand the coverage to both nanoparticles and chemical release in real-world conditions.

Regulating mass, and thereby larger particles, is important particularly for marine pollution, as the over 50% reduction in the population of coho salmon on the west coast of North America shows. This die-off has been conclusively linked by academics to a preservative compound found primarily in tyres. By this very fact, it can be seen that it is not only the particles themselves that is causing the issue, but the chemicals leaching out as those particles settle in the environment. Furthermore, these same tyre chemicals are being seen on a widespread basis in human foodstuffs and excreta.

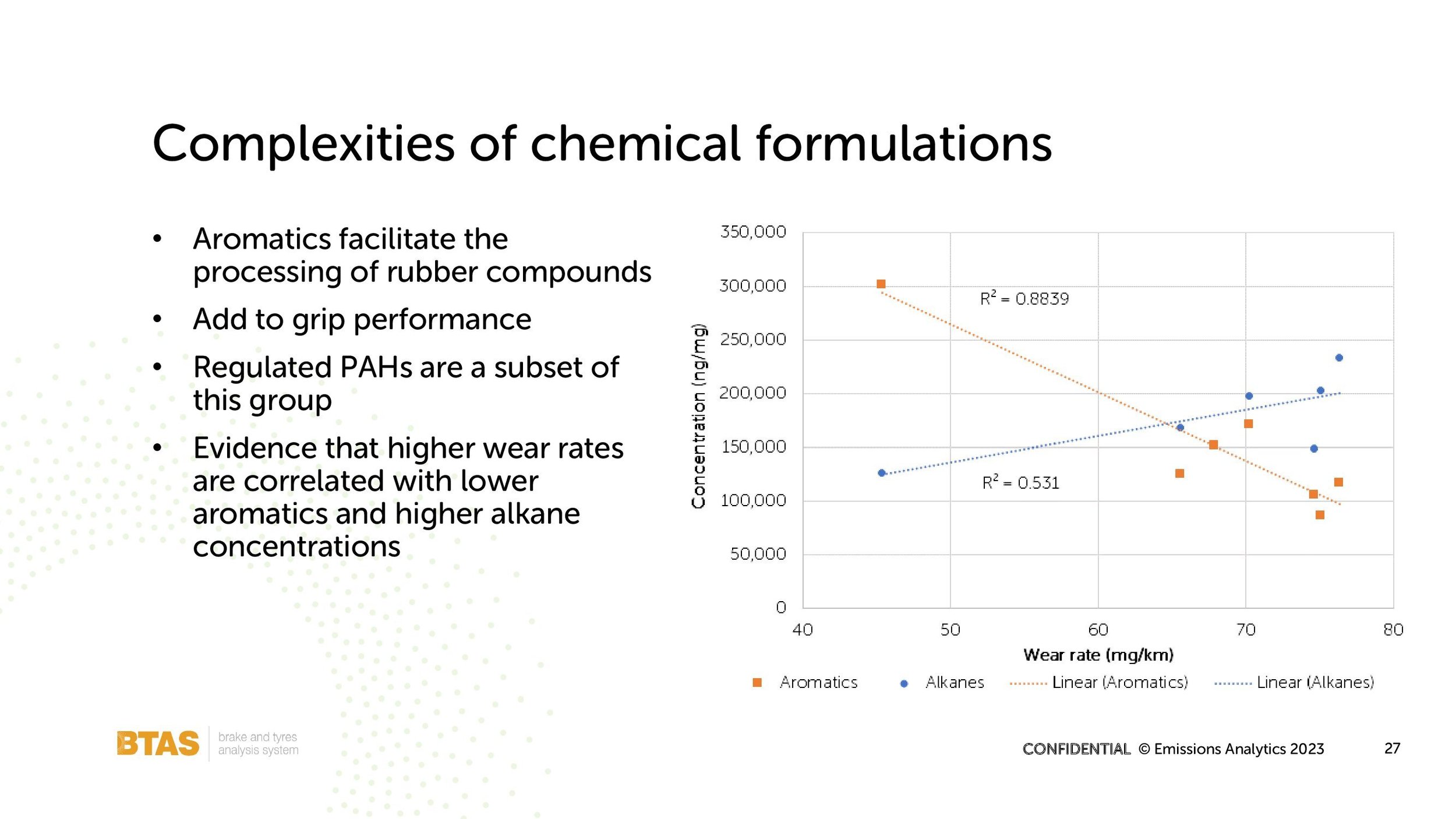

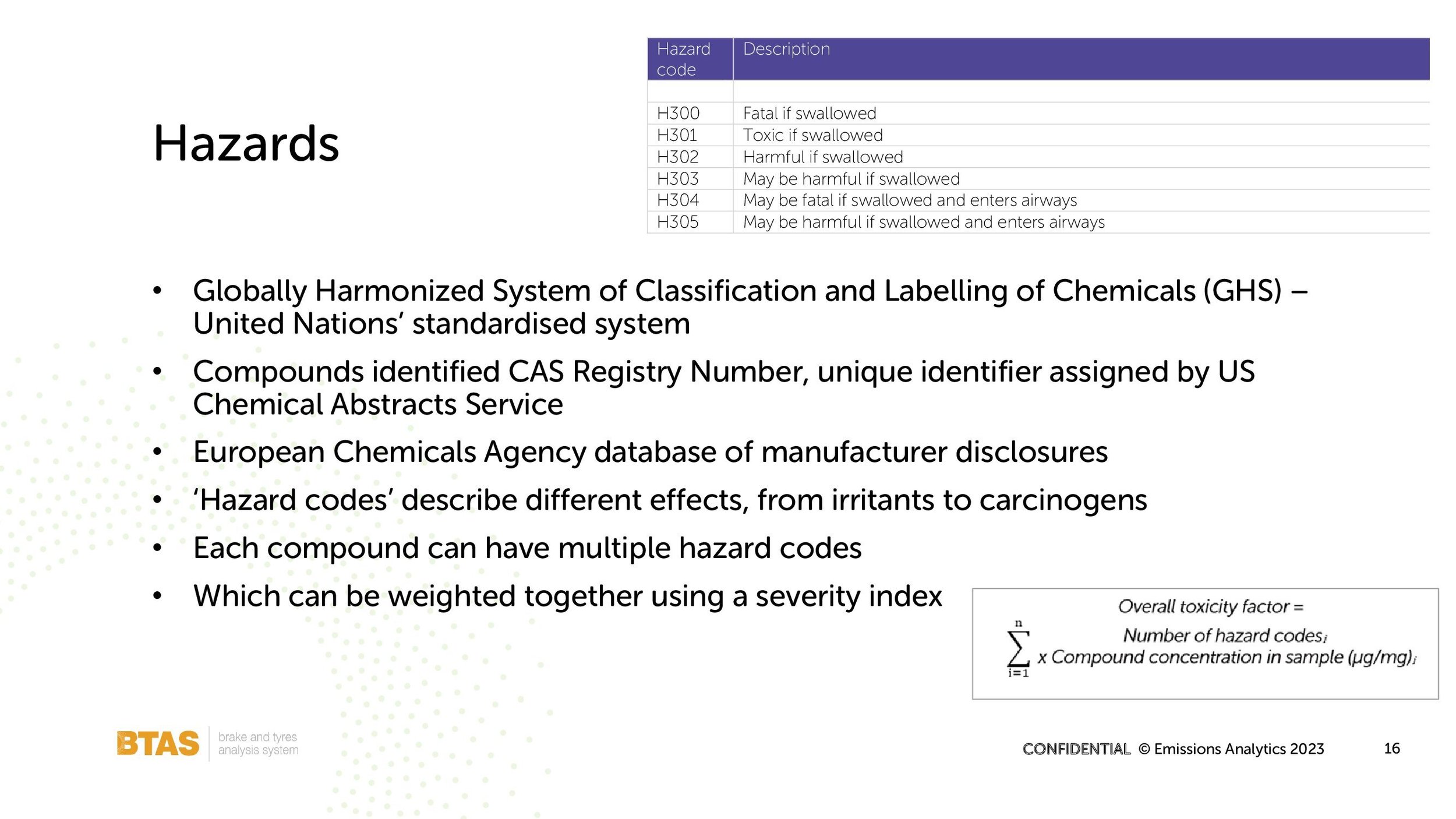

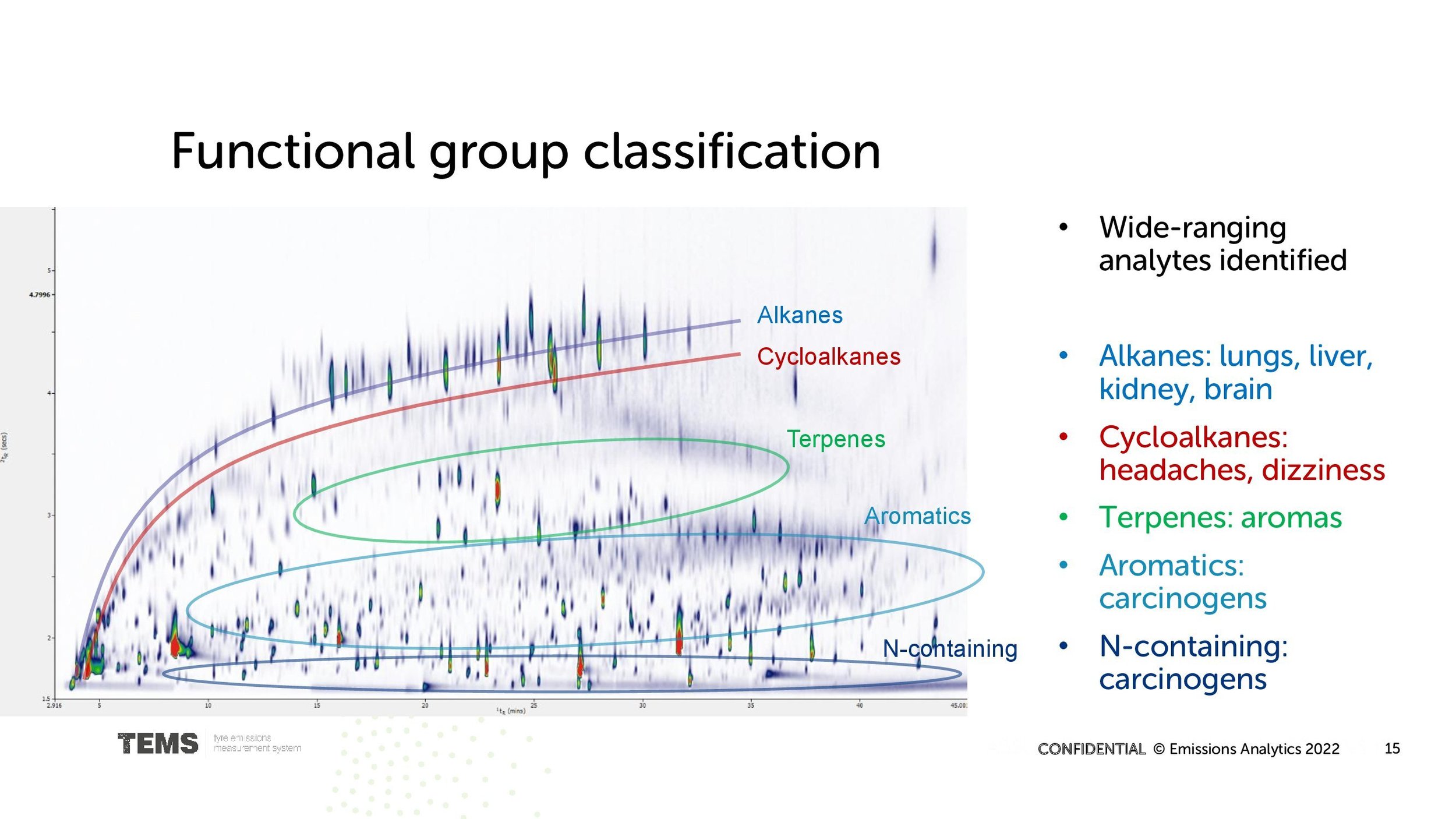

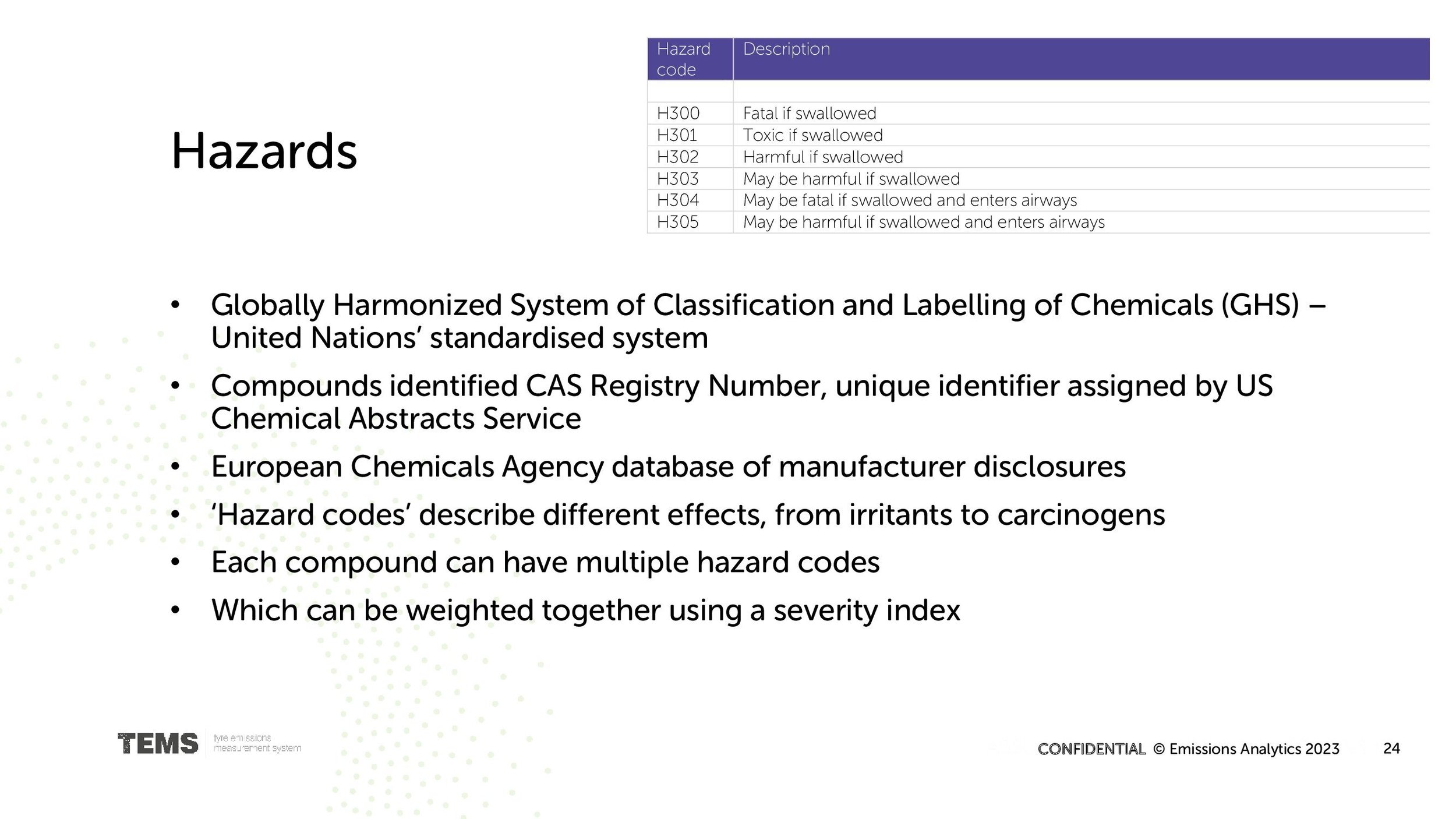

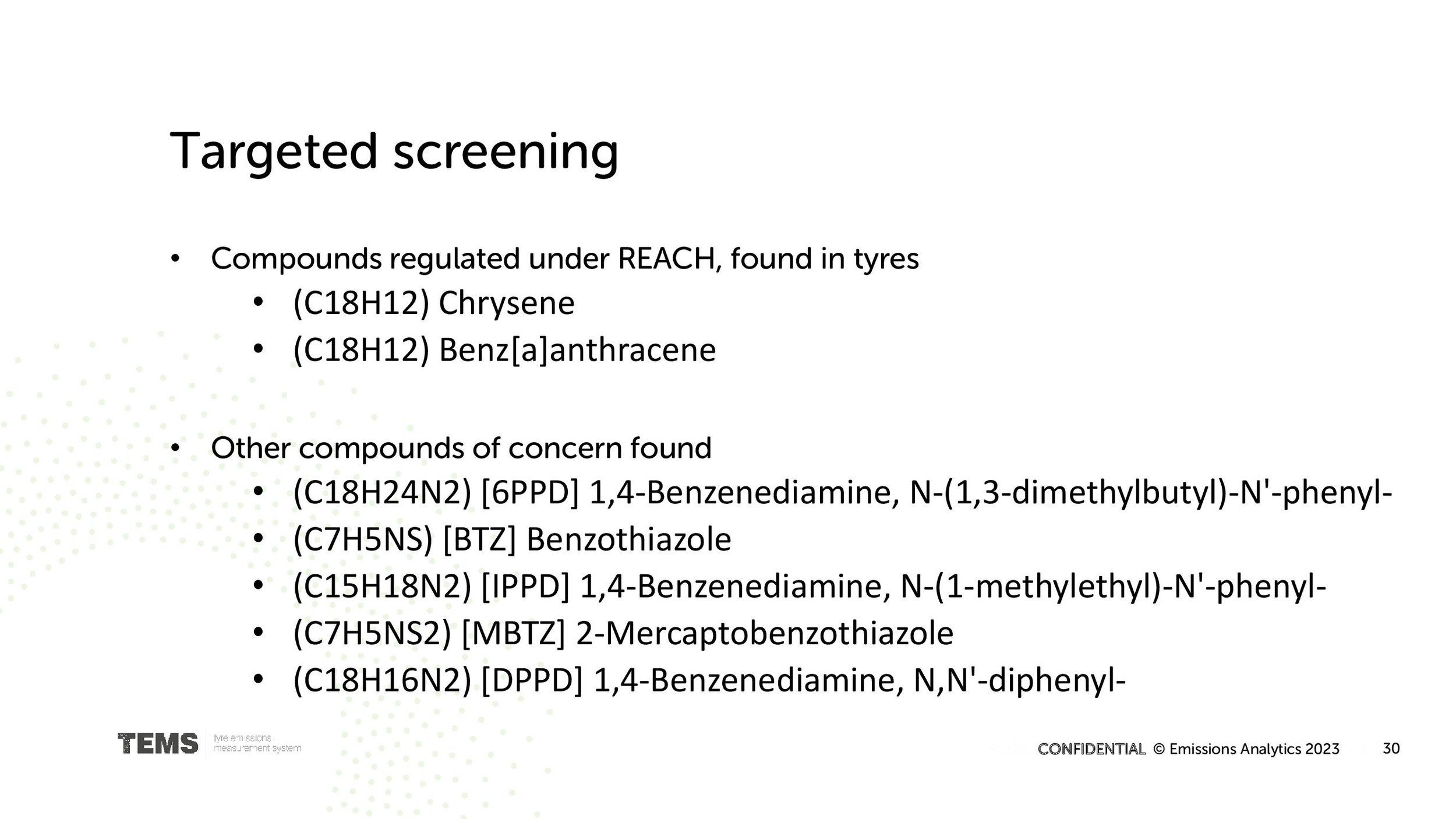

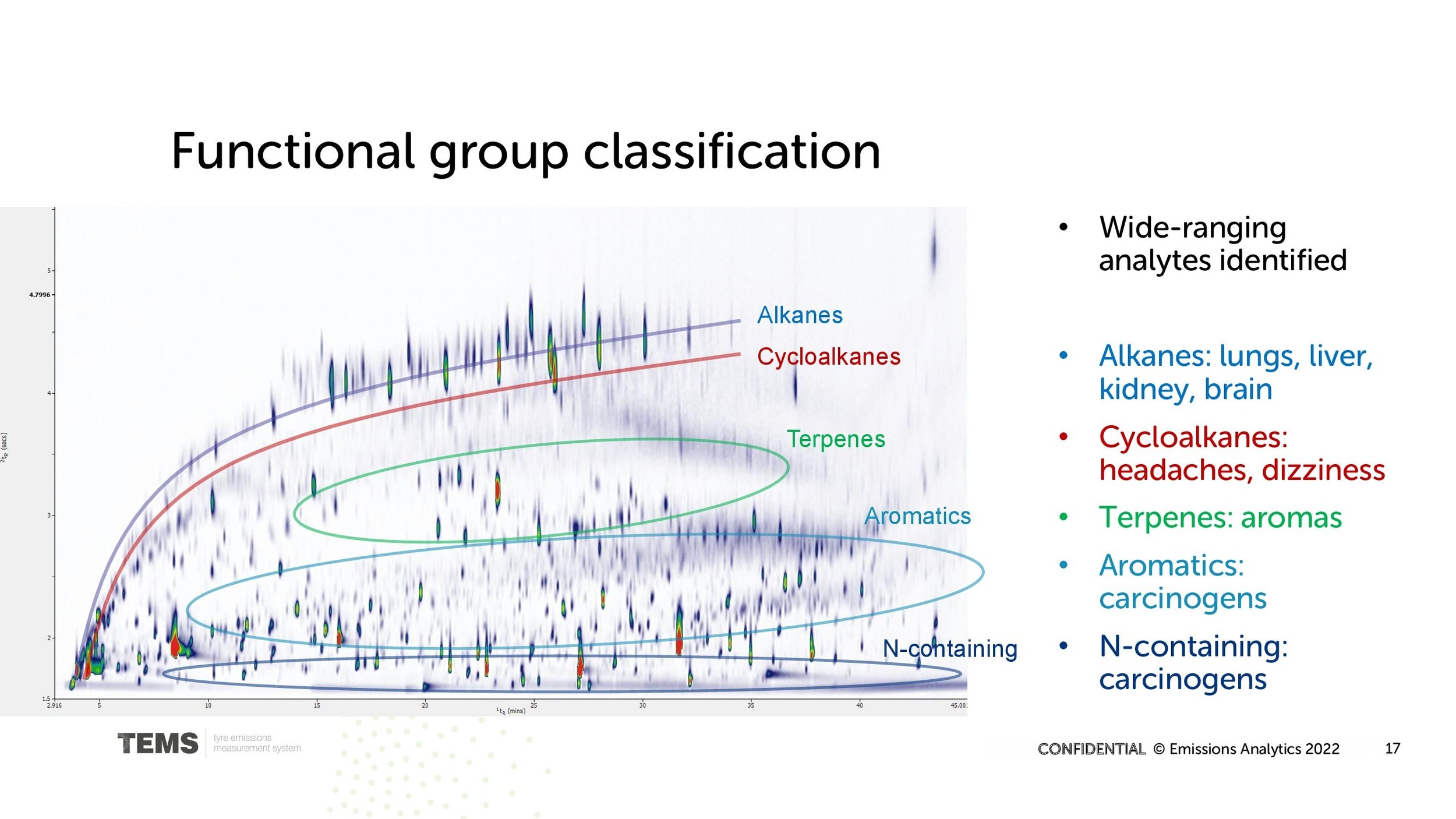

These chemicals are typically volatile organic compounds. Within this broad collection there is group of aromatic compounds, many of which are carcinogenic, such as polycyclic aromatic hydrocarbons (PAHs). To some extent these are regulated at the tailpipe currently through the total hydrocarbons limit value, although this could also be made more stringent and targeted to the most potentially toxic individual compounds. Eight compounds are also restricted under the REACH chemical regulation, but the coverage is too narrow and the limits too accommodating. Emissions Analytics presented on this topic at the fifth session of the UNECE Task Force on Tyre Abrasion on 30 September 2022¹. There is regulatory precedent from Switzerland, where the 2014 particle number standard (SN 277206:2014) included a secondary emissions test for certain target chemicals—including PAHs and nitro-aromatics—based on the US Clean Air Act section 202².

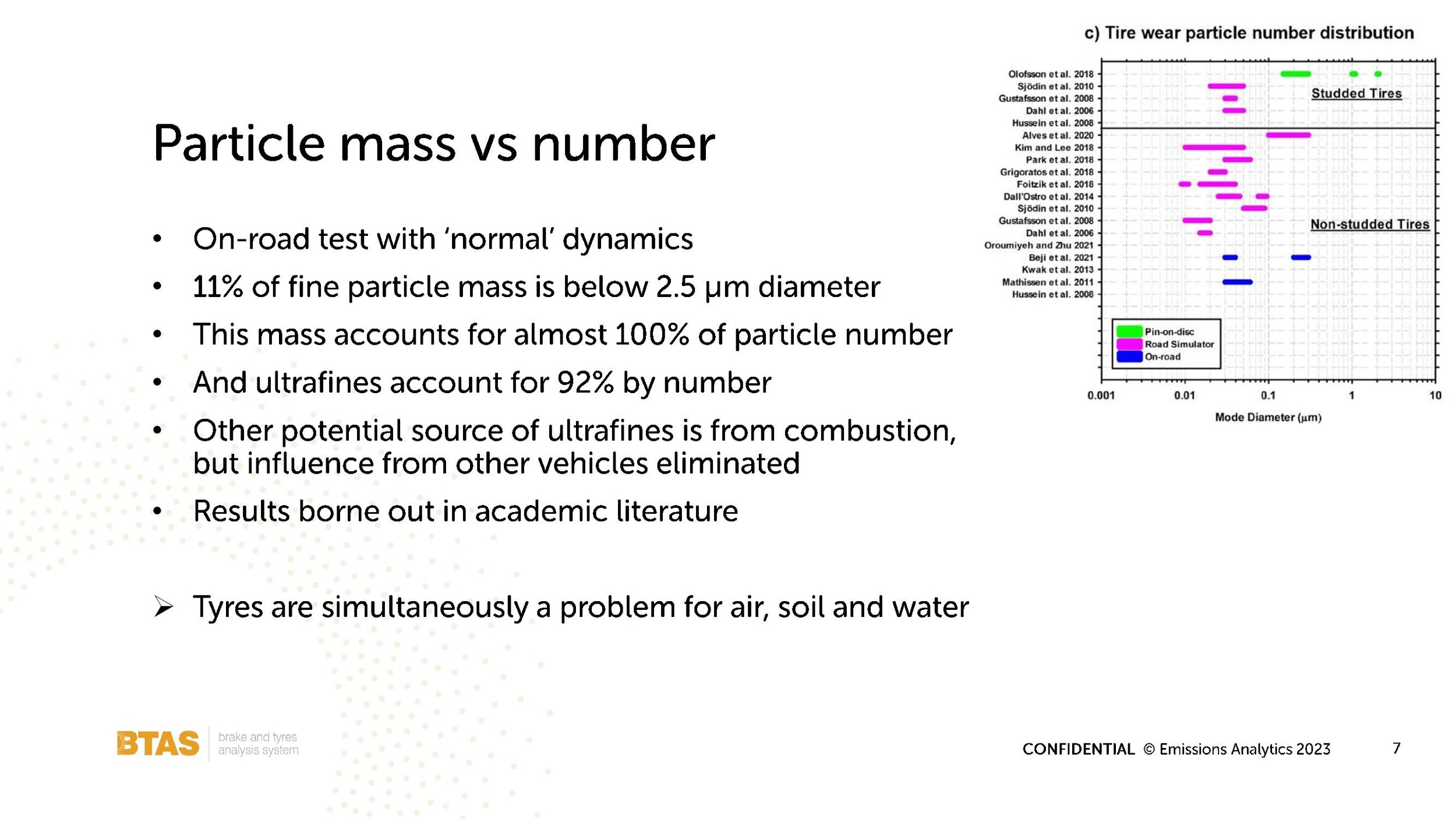

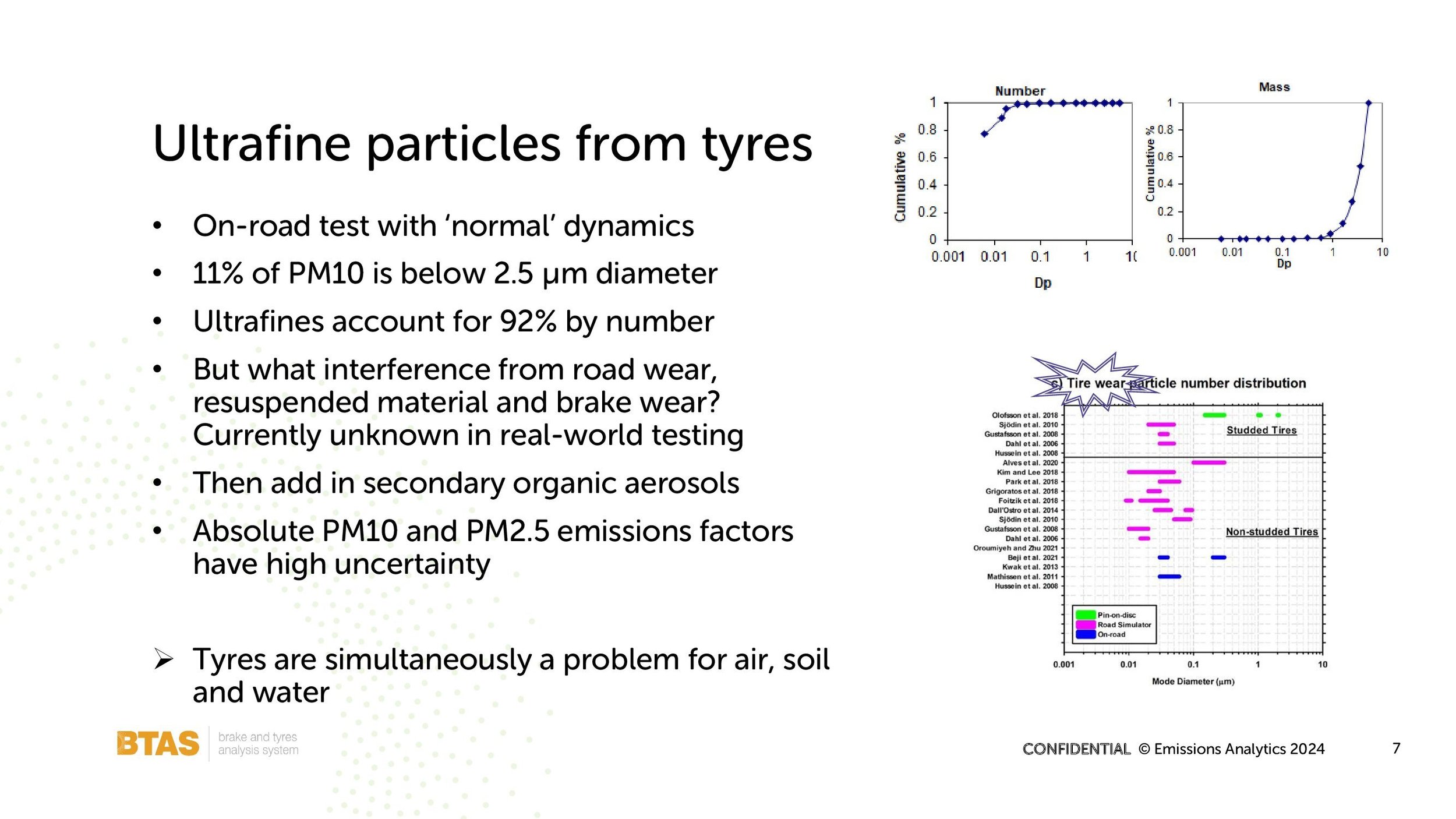

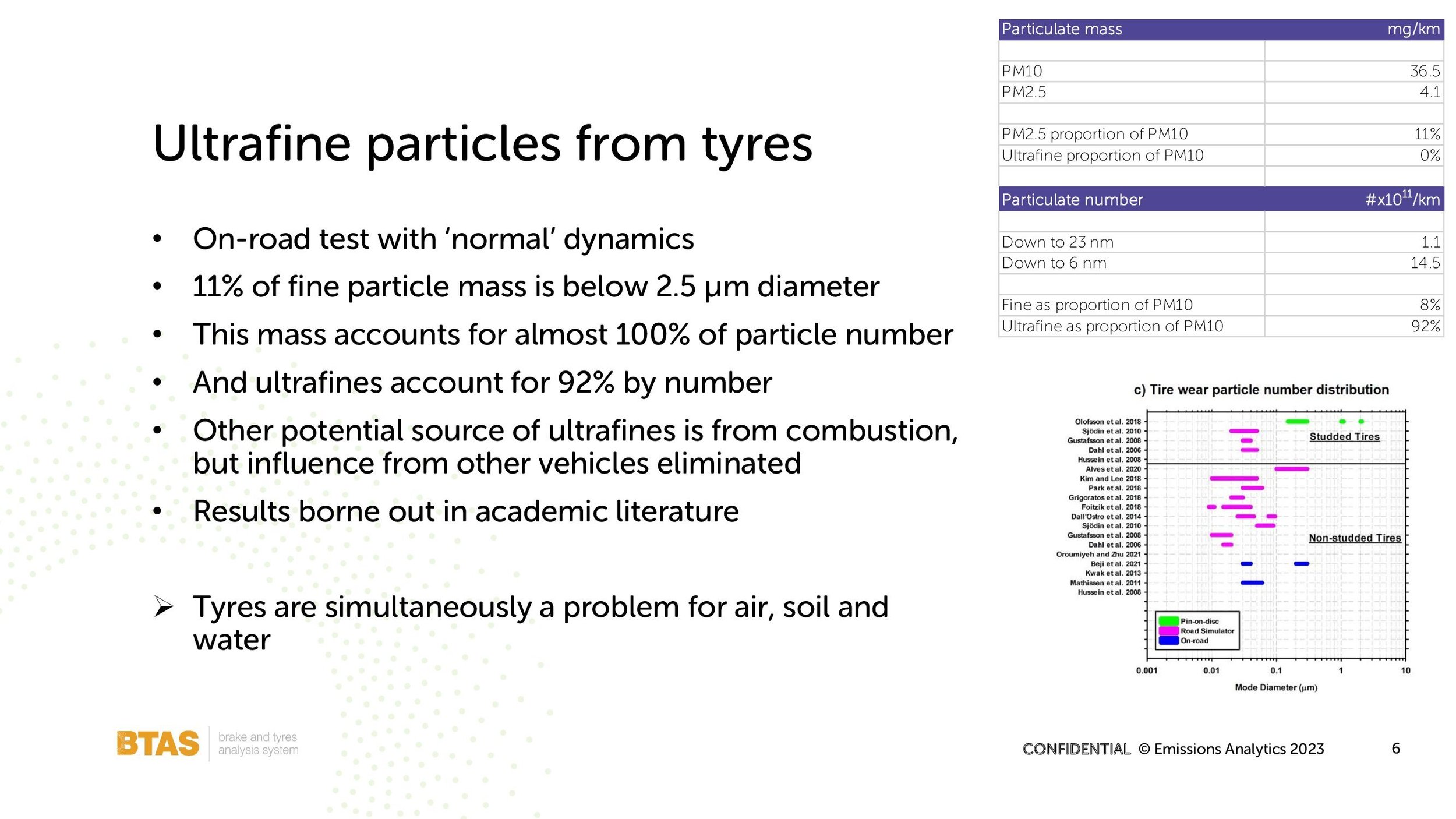

Nanoparticles are already regulated at the tailpipe since Euro 5. This intervention has been highly successful in reducing in-use emissions by particle filters in most vehicles, and measurement of these ultrafine particles is being expanded into the periodic technical inspection regimes in a number of European countries, which in all likely will deliver further significant reductions in real-world particle emissions. As the evidence for the negative health outcomes from chronic and acute exposure to nanoparticles becomes ever clearer, the value of this regulation grows. Yet, there are no current plans to regulate the same particles from tyres, despite tyres being made of the same underlying fossil materials as liquid fuels. Multiple academic studies have shown that tyres release large numbers of these particles in real-world use. Particle number measurement from tyres has been included for many years in the investigations of the Joint Research Centre of the European Community and the Particle Measurement Programme³, and such efforts should be accelerated to address this growing environmental issue.

In summary, we call on European regulators to apply the same approach they have applied to the tailpipe to the growing issue of tyre emissions. Particle mass, particle number and volatile organic compounds released from tyres must all come within a successful Euro 7 regulation at the earliest opportunity.

Signatories:

Nick Molden, Chief Executive Officer, Emissions Analytics

Dr Andreas Mayer, Chairman of the Scientific Committee, VERT Association

Footnotes:

Source: Nick Molden | Dr Andreas Mayer

Posted 27 June 2023 on Dieselnet

Champagne Supernova?

When an exploding star led to the observation of supernova SN 2003fg in 2003, it was nicknamed the ‘Champagne Supernova’ due to its unusual brightness, and its inexplicably great mass. Many supernovae eventually succumb to their own weight, leaving behind a black hole. Are we at this stage with battery electric vehicles (BEVs)?

A bright light, with a heavy weight

When an exploding star led to the observation of supernova SN 2003fg in 2003, it was nicknamed the ‘Champagne Supernova’ due to its unusual brightness, and its inexplicably great mass. Many supernovae eventually succumb to their own weight, leaving behind a black hole. Are we at this stage with battery electric vehicles (BEVs)? Their prospects are currently shining brightly despite their literal weight as well as their likely wider toll on the environment, from watercourses to the seabed, due to their production. Hybrids, by contrast, tread relatively lightly on the planet, yet give off a more muted glow of past glory – perhaps more like a red dwarf. In this newsletter we want to consider a further way in which vehicle size and weight matter, and why the BEV industry must address this rapidly if it is successfully to deliver pollution reduction.

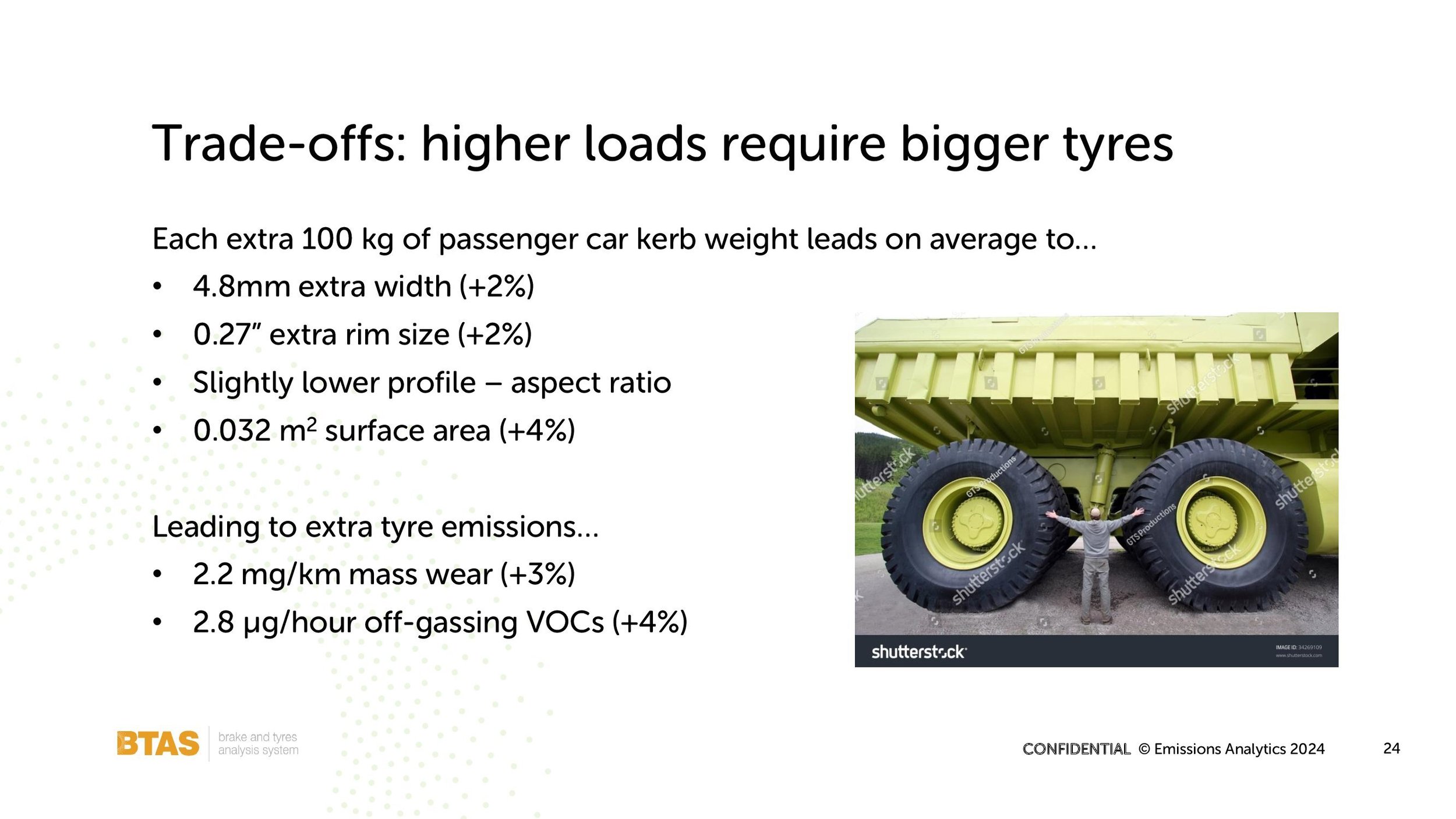

Astronomical parallels aside, we can simply say that BEVs are too big and heavy right now. Yes, there are heavy internal combustion engine (ICE) vehicles, but on average BEVs are around 40% heavier and 40% bigger like-for-like, as set out in a previous newsletter. This trend may well continue, and the weight premium increase, as BEVs come increasingly equipped with lithium ion phosphate (LFP) batteries as they are cheaper and require fewer scarce materials. It may even be the case that this weight leads to structural risks for transportation infrastructure, such as roads and car parks, although this has yet to be proven.

While this is all true, it is easy to get stuck in a pattern of ‘trading averages.’ As Senecal et al meticulously pointed out, you can only assess the decarbonisation potential of BEVs in the US by looking at local-scale grid electricity, and marginal rather than average carbon intensities. Similarly, with vehicle selection, you can only judge the benefit by understanding the marginal changes. If someone replaces a frugal gasoline car with a larger BEV, that is likely to be worse for the environment in the round. Equally, switching from a large gasoline V8 to a small city BEV is very likely to be better. It is easy to make simplistic ‘stop burning stuff’ slogans stick when you conjure up the image of a pre-particle-filter diesel being replaced by a gleaming Tesla. However, for the same investment, you are likely to get more pollutant and carbon dioxide (CO2) emissions reduction from trading those old diesels up for the latest full hybrid electric vehicles (FHEVs). So, what we mean by an ICE vehicle, and the variation in performance within that group, matter. Put another way, it is not the optimal approach to dispense with all ICE technology just because many are high-emitting, just like it would be wrong to reject all BEVs just because many are currently very heavy.

Our previous newsletter suggested that tailpipe emissions from FHEVs had reached a ‘do no harm’ status, by showing levels more than 90% below a range of air pollution legal limits. What this did not show was whether those apparently low levels were in fact sufficiently de minimis to be of little concern, or whether we were still burning stuff in a detrimental way for air quality. An immediate caveat to make is that there is a relevant difference between this European test and apparently similar US vehicles. In Europe, unlike the US, a large and increasing proportion of gasoline ICE vehicles are equipped with particle filters, which significantly reduce the particle mass and number emissions from the tailpipe. Therefore, US particle emissions remain concerning and, as a result, there is greater benefit in switching to BEVs in that market, in the absence of widespread adoption of these filters.

That said, we can look more closely at the volatile organic compound (VOC) emissions from the same test to put the results in context. We showed that there were 4.38 mg of tailpipe emissions over our EQUA test, or 0.03 mg/km. This compares to the most relevant official limit of 100 mg/km for total hydrocarbons, which puts the car more than 99% below the limit. These low emissions were compared to the 330 mg emitted from the tyres on the same test. But, still, how bad is 0.03 mg/km? A recent paper, from March 2022, in Environmental Science & Technology by Wang et al, measured the VOC emissions from four humans seated in a controlled climatic chamber, using proton transfer reaction time-of-flight mass spectrometry and gas chromatography. Without the presence of ozone, the emissions averaged 2.2 mg per human per hour, rising to 4.6 mg in the presence of ozone. Averaging these, and applying the result to the length of the EQUA test, it would imply that a human driver would emit 12 mg of VOCs in total. Therefore, during the EQUA test the driver may have emitted three times more pollution from his body than came out of the tailpipe of the car being driven. Stop metabolising stuff!

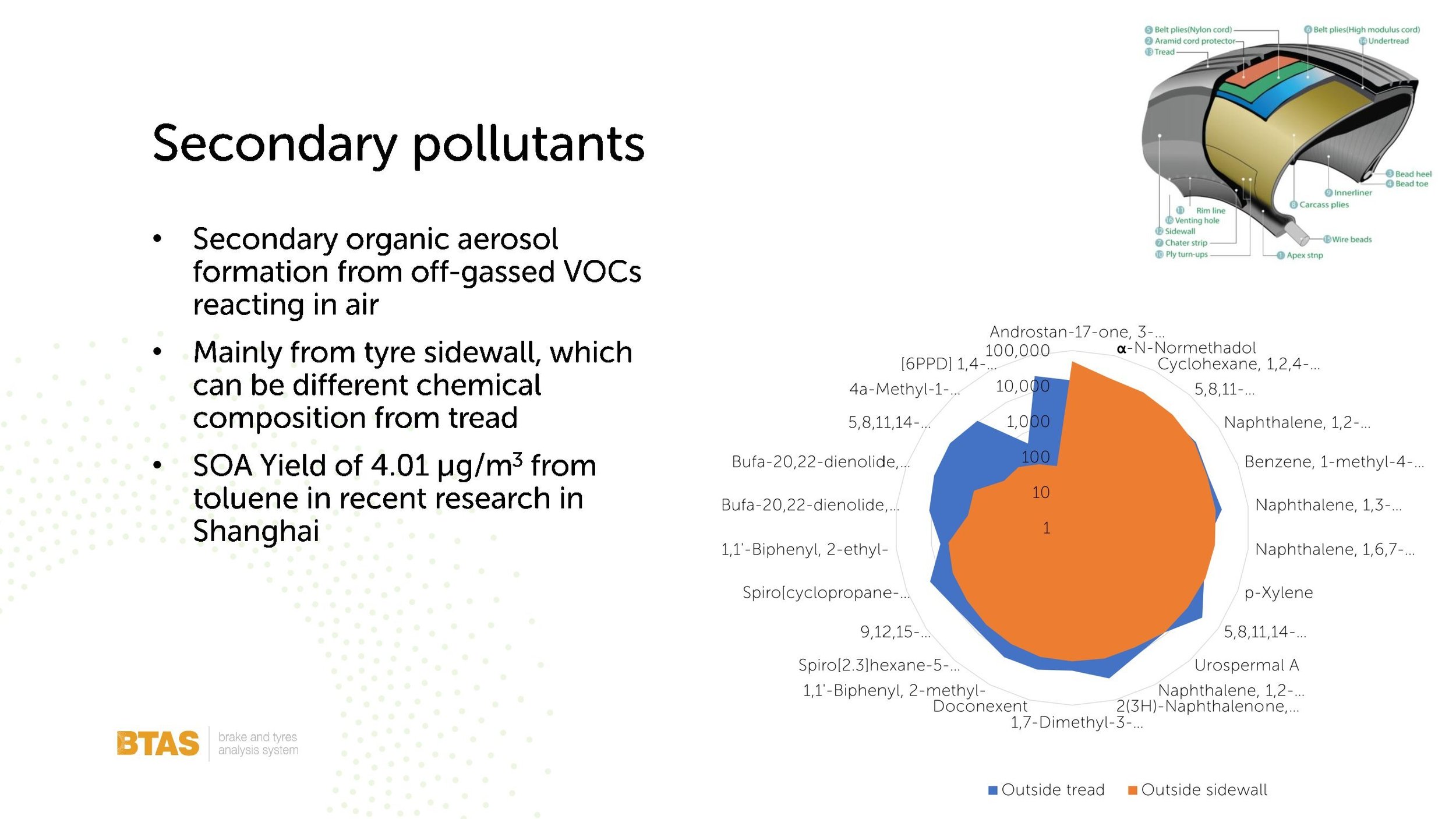

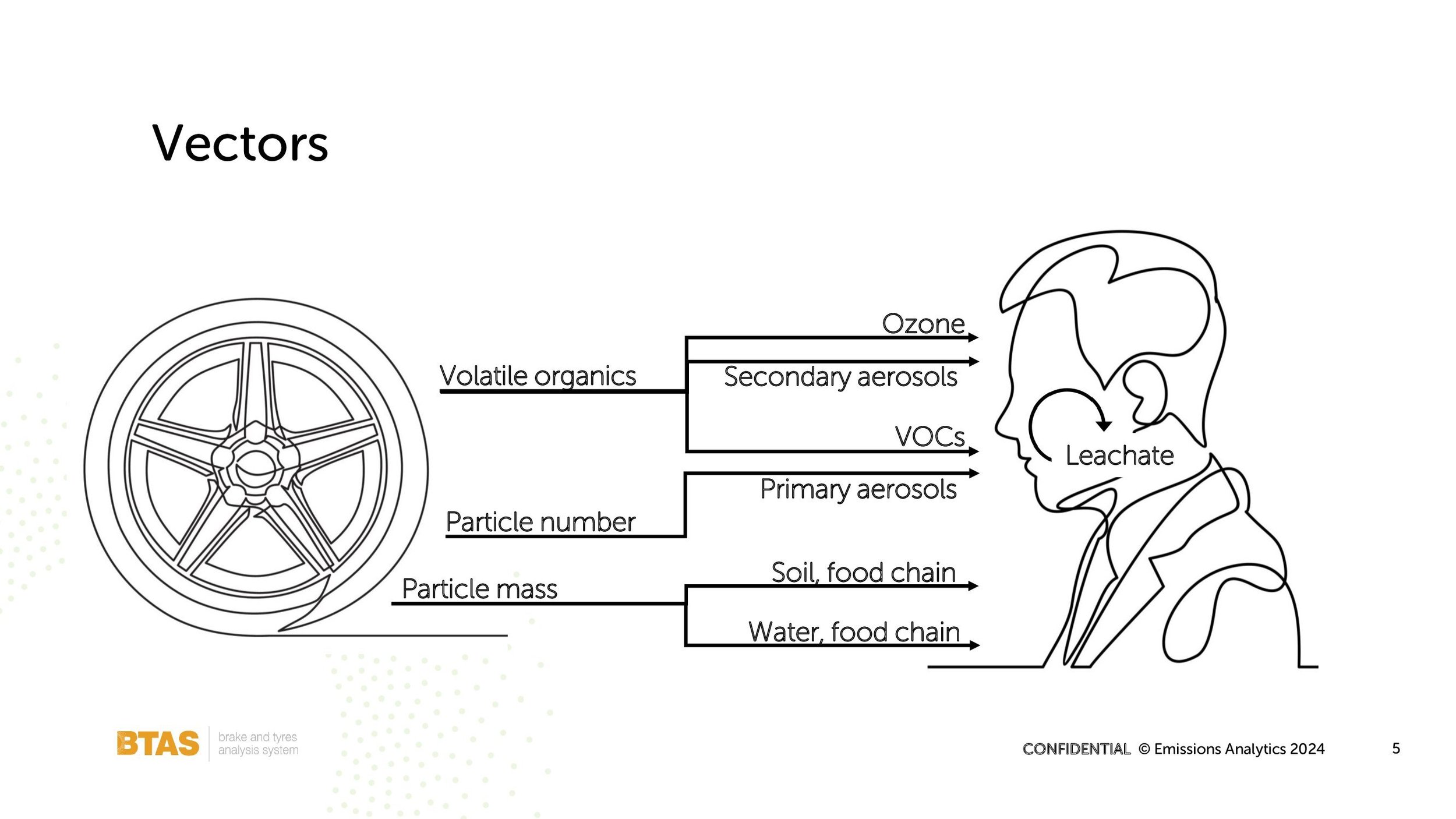

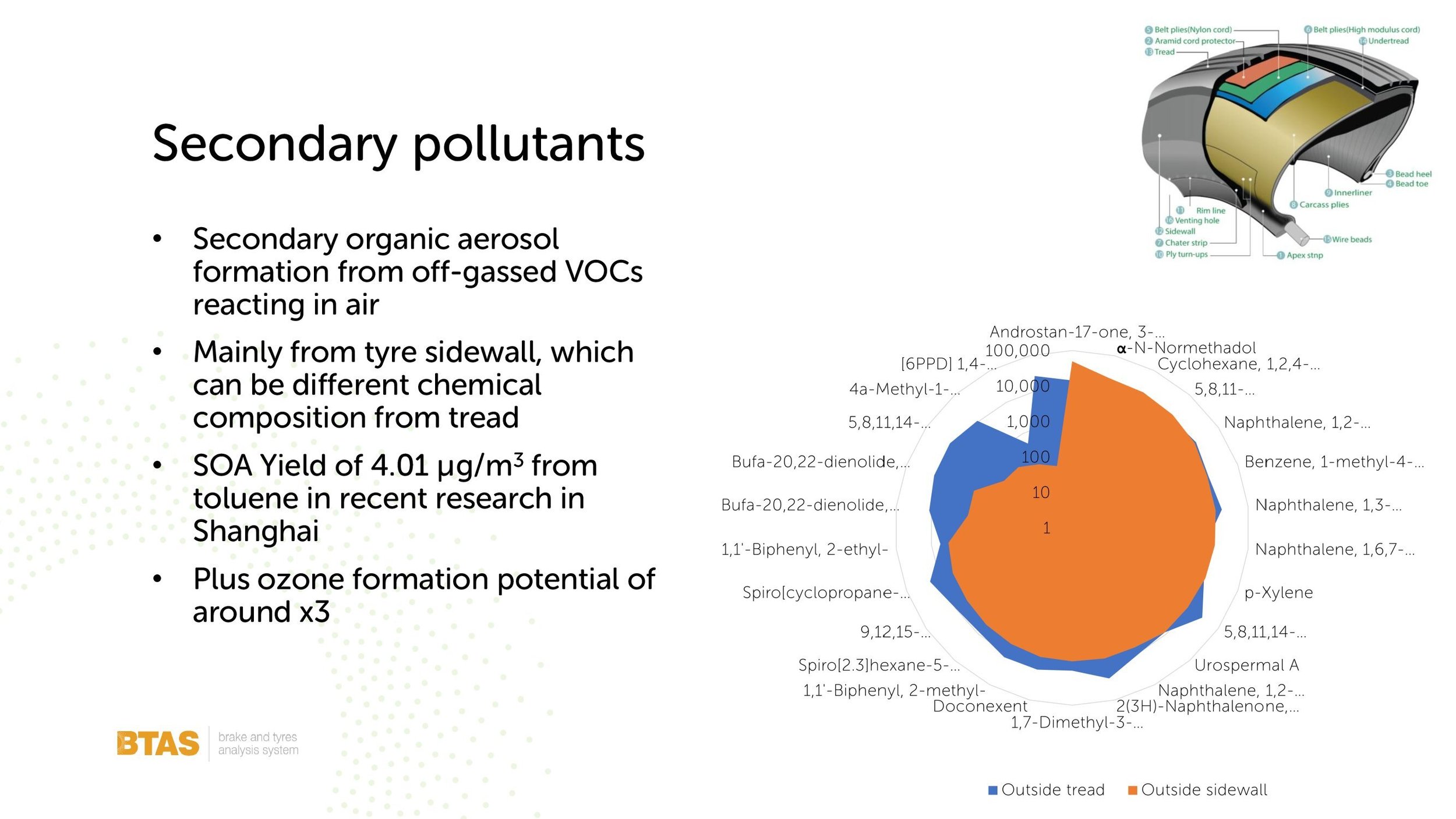

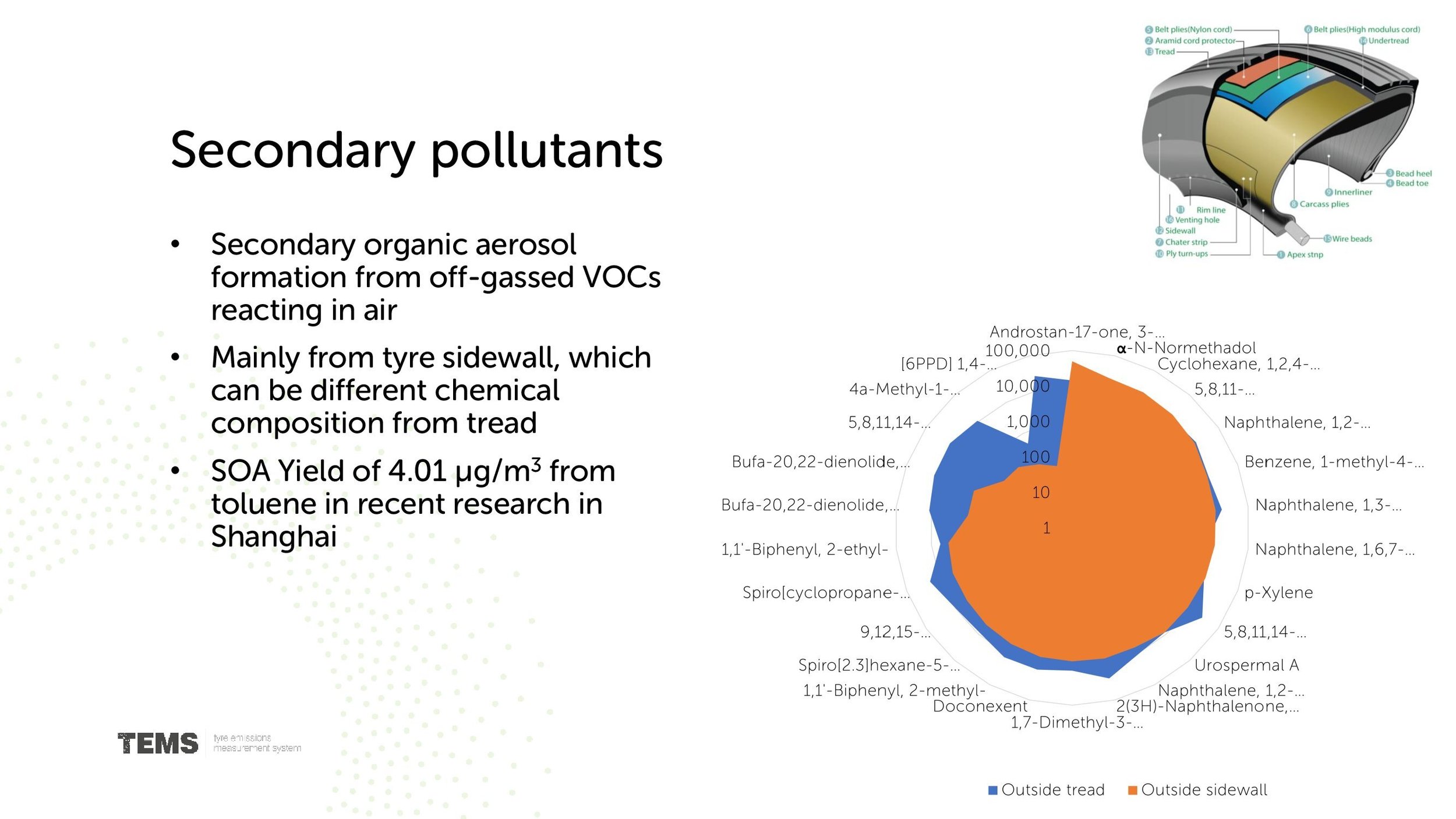

So, we can see that the levels of regulated exhaust pollutant emissions from the FHEV are now trivially low. Of those not regulated, the sub-23 nanometre, ultrafine particles are probably the greatest omission, which is being addressed by regulators soon, as set out below. What is left is a more serious concern about VOC emissions, especially from tyres. There are three main reasons we should be concerned about such emissions. First, VOCs can have a direct health effect through inhalation or contact with the skin – many are harmless, but the worst organic compounds can be carcinogenic. Second, VOCs can react in the air to create ‘secondary organic aerosols’ (SOA), i.e. new particles, for which the health and environmental effects are well described elsewhere. Third, these organic compounds have an ‘ozone formation potential’ (OFP), ground-level ozone being one of the main constituents of the smog hanging over city skylines.

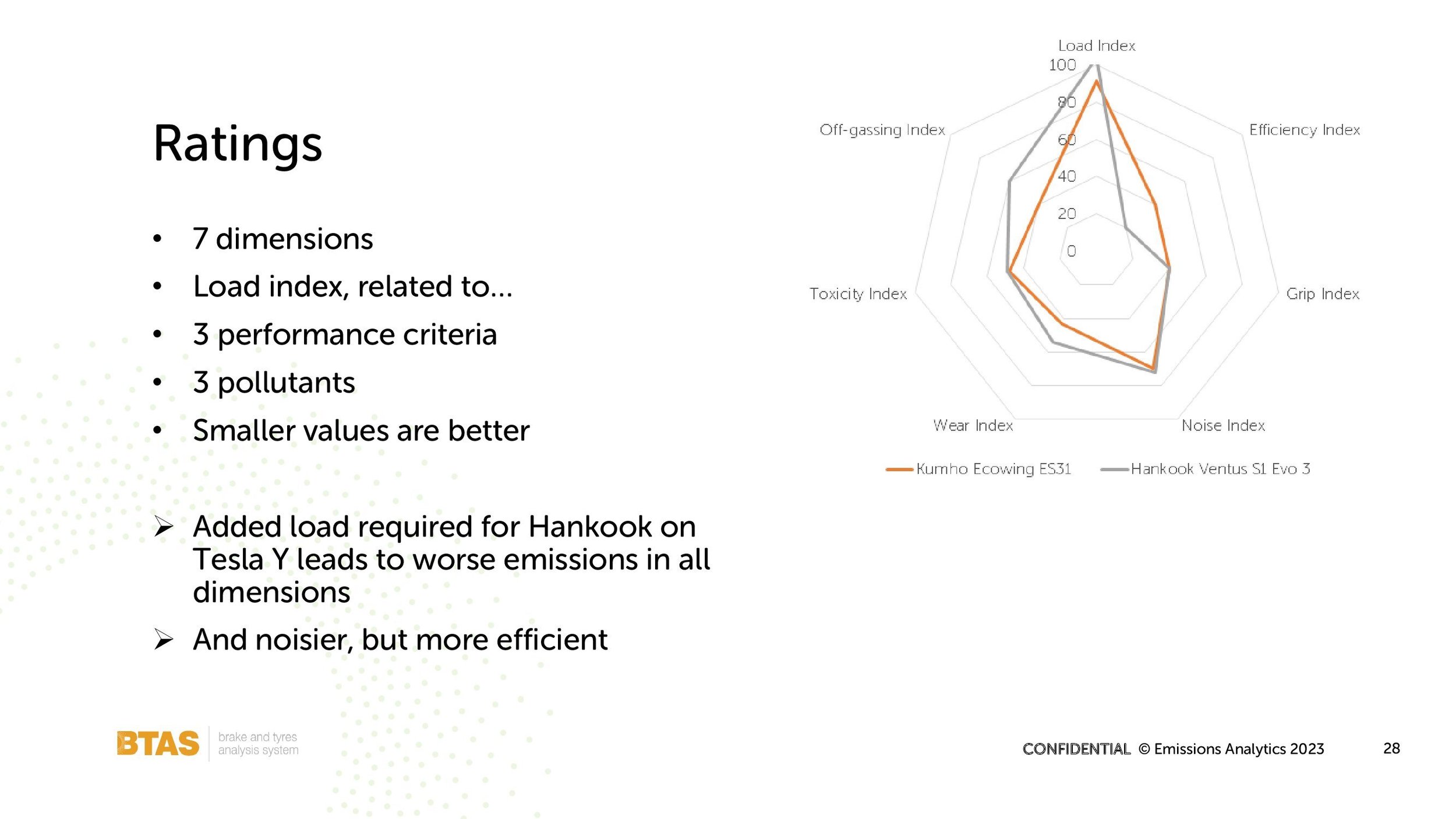

From the testing on the Tesla and Kia described above, we see tyre VOC emissions of 2.2 mg/km from the Kia and 6.1 mg/km, from the larger-wheeled Tesla. Taking the ‘secondary organic aerosol formation potential’ (SOAFP) for five target compounds and the average value for the remainder from Wang et al (2017), this implies a maximum possible particle formation of between 0.03 mg/km and 0.1 mg/km. The latter is shown in the table below, which is from the Hankook tyre on the Tesla. This may sound low, but tailpipe particle emissions are now as low as 0.02 mg/km, so the tyre VOC emissions could more than five times the tailpipe mass emissions.

Using a similar approach for ozone formation, the test could have yielded up to 13.2 mg/km. There are no direct regulatory benchmarks to compare this to, however.

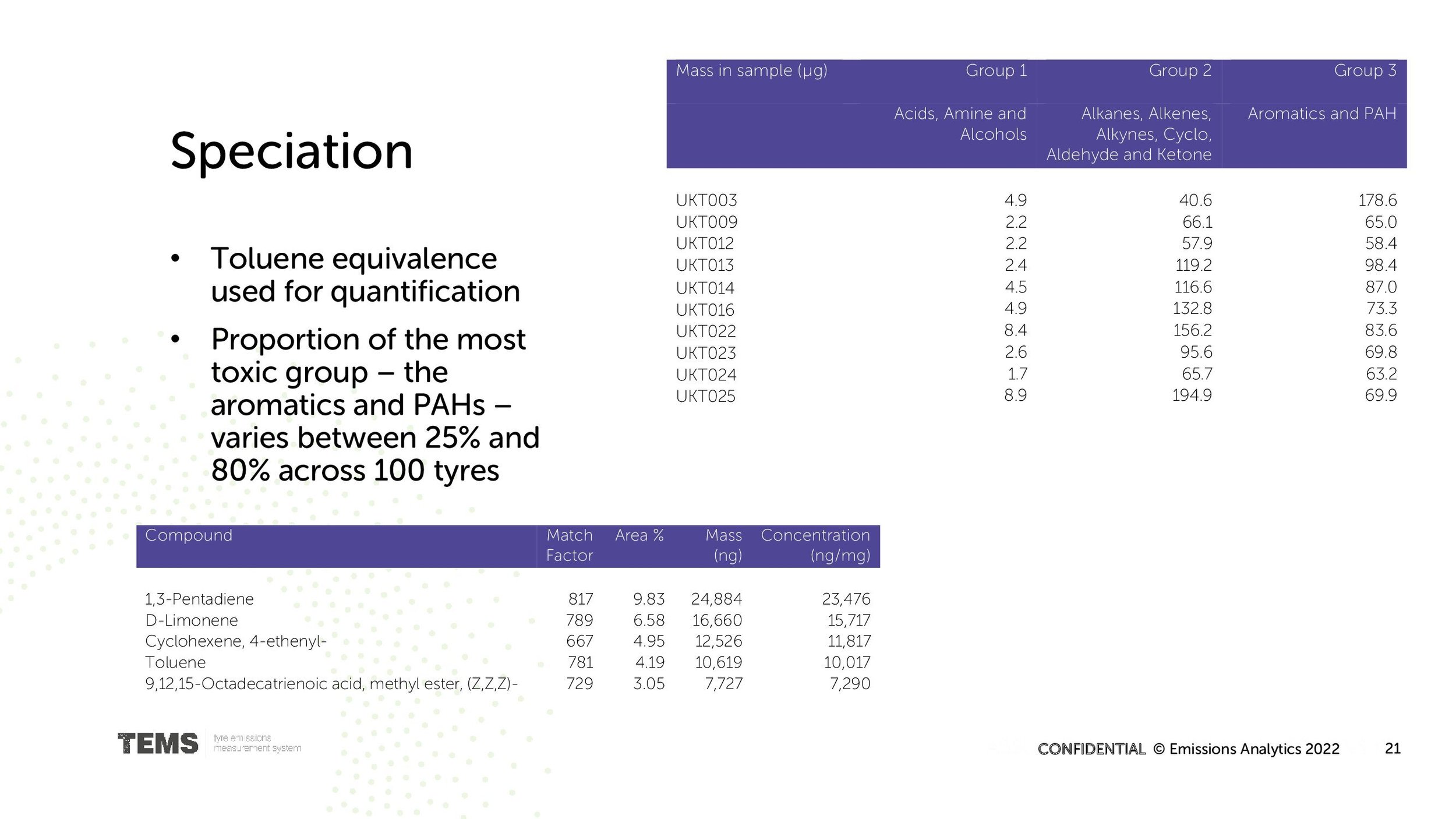

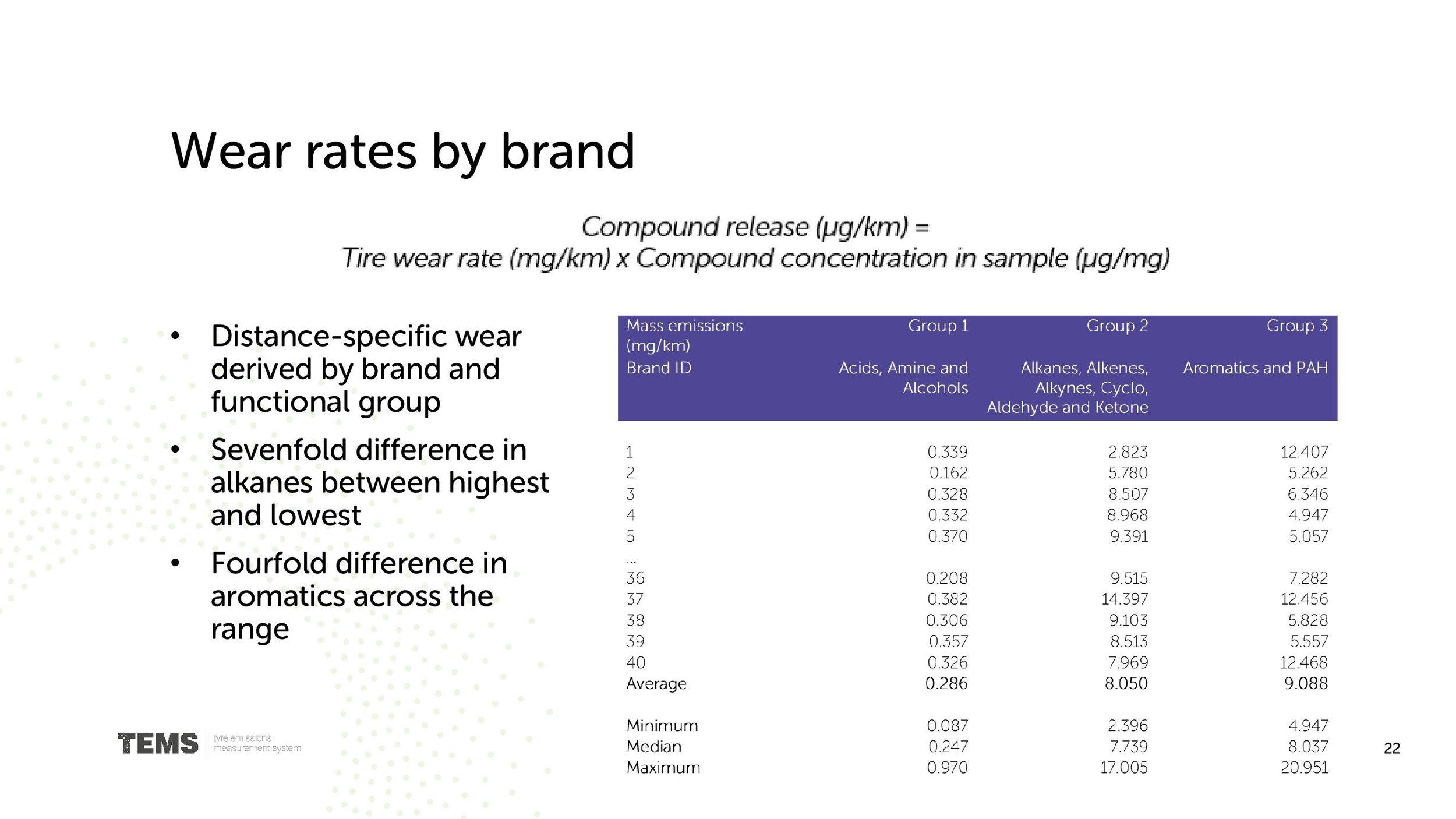

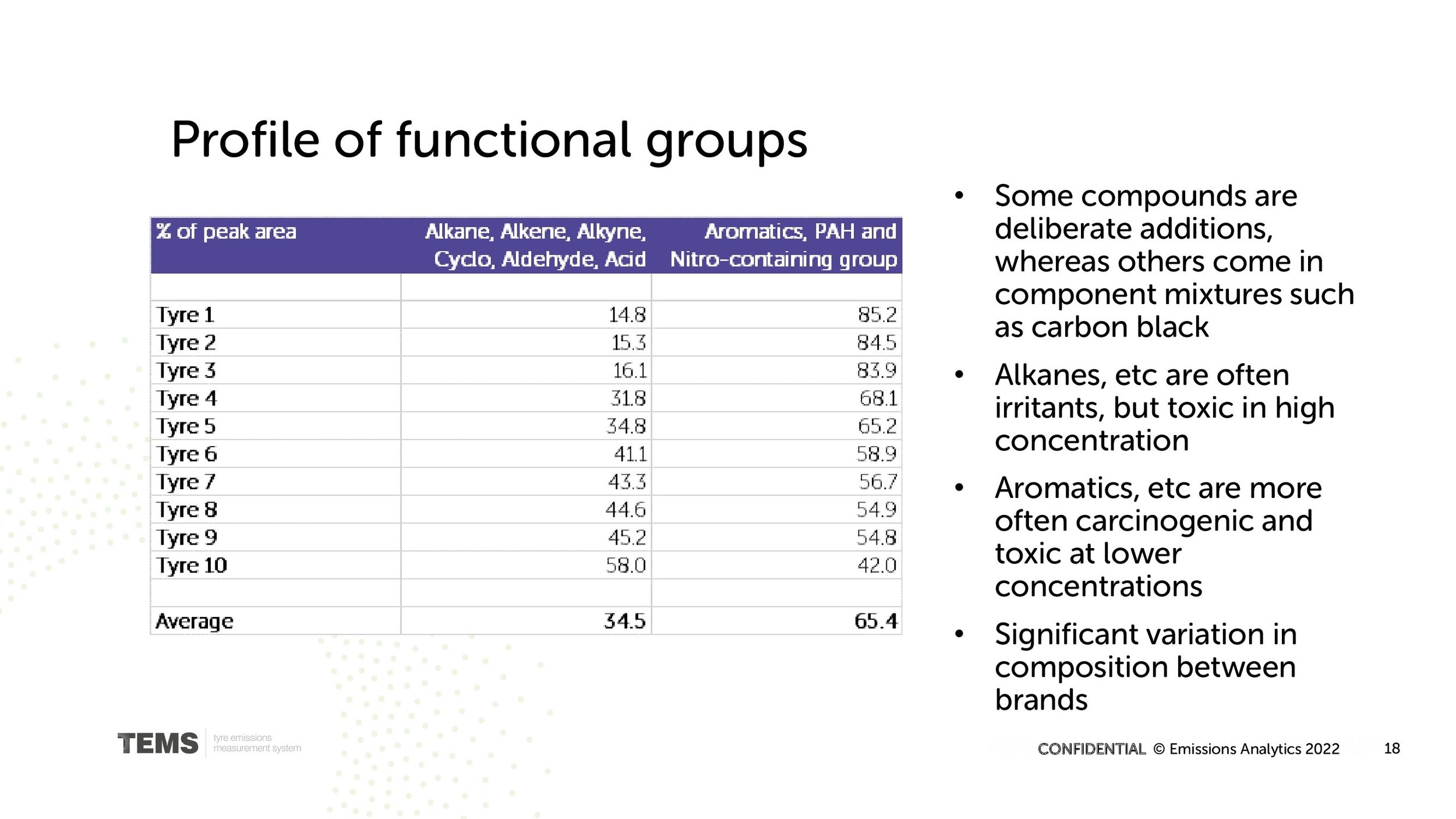

This shows not only that tyre size matters, but that chemical composition does as well. From over three hundred tyres tested by Emissions Analytics, the surface area of light duty vehicle tyres – from which the VOCs evaporate – can vary by around 100%, depending on whether you have a 155/60 R15 skinny summer tyre, or a 235/65 R17 specialist SUV tyre, for example. Across 73 tyre manufacturers tested, the proportion of aromatics – some of the more potentially toxic compounds, and highlighted compounds in the table above – vary in concentration from 78 to 582 micrograms per milligram of sample. In other words, the concentration of certain chemicals, and the surface area from which they can evaporate, varies significantly between tyres. As a consequence, vehicle size and weight, with the tyres that accompany that, evidently affect emissions in use, in addition to the materials required for their construction.

This shows not only that tyre size matters, but that chemical composition does as well. From over three hundred tyres tested by Emissions Analytics, the surface area of light duty vehicle tyres – from which the VOCs evaporate – can vary by around 100%, depending on whether you have a 155/60 R15 skinny summer tyre, or a 235/65 R17 specialist SUV tyre, for example. Across 73 tyre manufacturers tested, the proportion of aromatics – some of the more potentially toxic compounds, and highlighted compounds in the table above – vary in concentration from 78 to 582 micrograms per milligram of sample. In other words, the concentration of certain chemicals, and the surface area from which they can evaporate, varies significantly between tyres. As a consequence, vehicle size and weight, with the tyres that accompany that, evidently affect emissions in use, in addition to the materials required for their construction.

What does this mean for regulation? The current Euro 7 proposals are generally a sensible step, as set out in a previous newsletter, not least to make the regulations more technology neutral and tighten ultrafine emissions limits. A less prominent part of the proposal is to tighten the ‘evaporative emissions’ test. This is designed to limit the VOCs off-gassed during refuelling and the use of vehicles, for example vapour escaping from the fuel tank. The test is conducted in a controlled chamber and the escaping VOCs collected over a one-hour period when the vehicle is hot followed by 48 hours when it is cool, all with the ambient temperature varying across a ‘normal’ range. Currently, the total emissions must be less than 2 grams, although this may be significantly reduced with Euro 7. This is relevant because the test, although not specifically designed to do so, will pick up off-gassing from the vehicle’s tyres. However, this is one respect in which Euro 7 is not technology neutral: the evaporative test only applies to gasoline vehicles. So, BEVs with large tyres have no limits applied.

In conclusion, we have shown the risks of myopically looking at tailpipe emissions, and the dangers of asserting the environmental impact of vehicles simply from the type of powertrain. In short, environmental logic points towards a mixed car parc made up mainly of smaller BEVs to cover town driving and larger FHEVs for more general purposes, brought about as quickly as possible in order to get the black hole of older, dirty cars off the road as soon as possible. Vehicle weight, and hence emissions, should be minimised to allow the smallest tyres that are safe and effective. This is a lower risk approach, and from an economic point of view a ‘lower regret’ option as we would not be gambling resources of potentially up to $1 trillion globally, according to some reports, on a maxi-BEV technology that may not deliver its promises. If we pivot to this lighter approach, in ten years’ time, as with 1990s Britpop Oasis’ champagne supernova, you might not have to wipe that tear away now from your eye.

Presentation: Emissions Analytics Tire Technology Expo Presentation 22 March 2023

Our CEO & Founder, Nick Molden recently spoke at the Automotive Tire Technology 2023.

CEO & Founder, Nick Molden spoke at the Automotive Tire Technology 2023.

Presentation: How to reduce emissions of micro particles from tyres to minimise health and environmental impact and avoid reputational damage

Our CEO & Founder, Nick Molden recently spoke at the Automotive Tire Technology 2023.

CEO & Founder, Nick Molden spoke at the Automotive Tire Technology 2023.

How tyre emissions hide in plain sight

Emissions testing is usually preoccupied by testing for known, worrisome chemicals in the environment. Often they are in small amounts or concentrated at hotspots. Sophisticated equipment is deployed to find and measure them. We obsess with ever-tighter regulation of these pollutants we know about, even well beyond the point of diminishing environmental returns.

But it's not especially an electric vehicle problem

Emissions testing is usually preoccupied by testing for known, worrisome chemicals in the environment. Often they are in small amounts or concentrated at hotspots. Sophisticated equipment is deployed to find and measure them. We obsess with ever-tighter regulation of these pollutants we know about, even well beyond the point of diminishing environmental returns. At the same time, emissions from tyre wear from vehicles are all around us, and inside us, but we hardly see it. There is so much of it, and it is camouflaged by its chemical complexity, that we don’t notice. It is visible but unperceived. We urgently need to reprogramme our perceptive faculties to recognise the danger right in front of us.

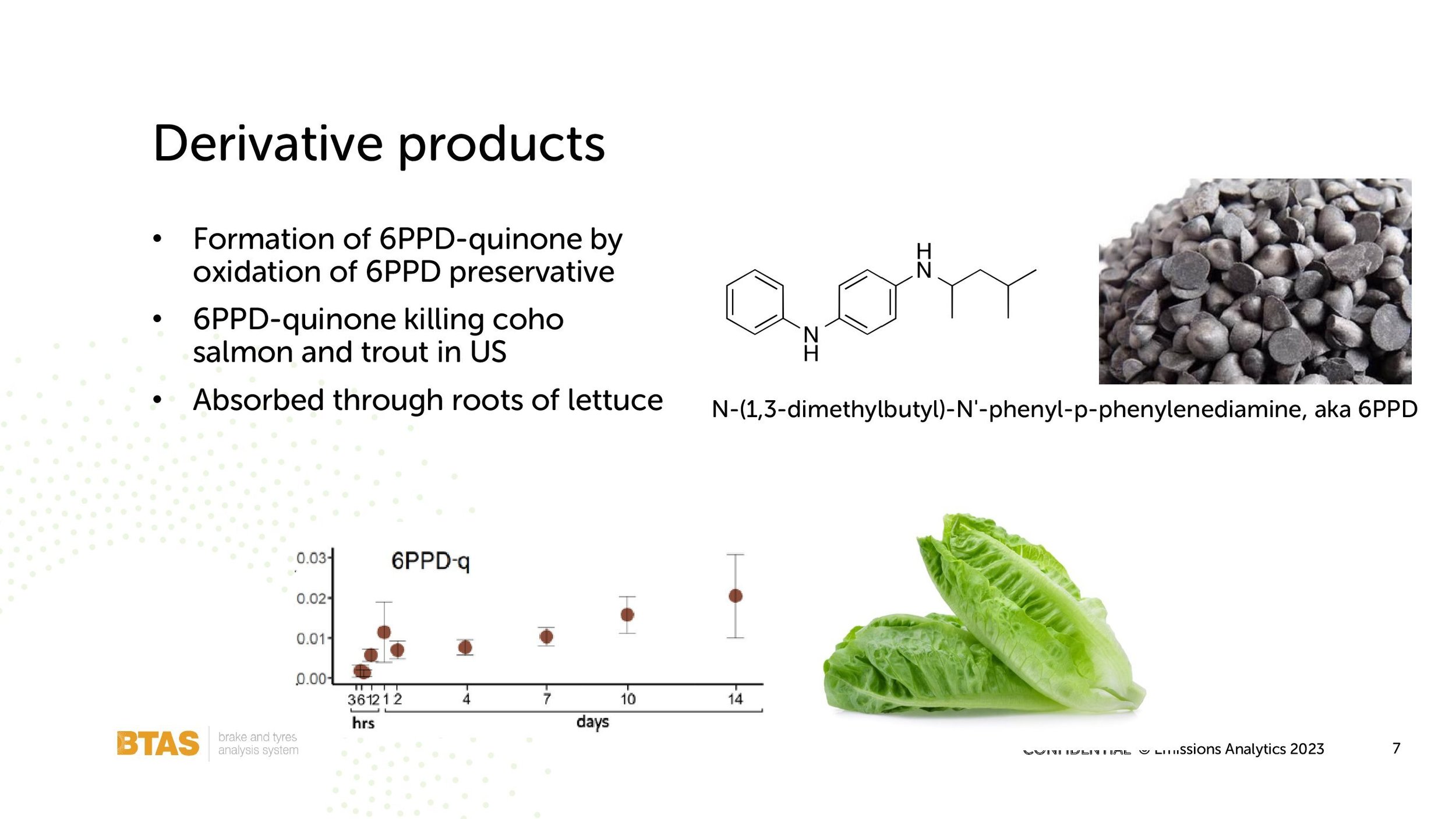

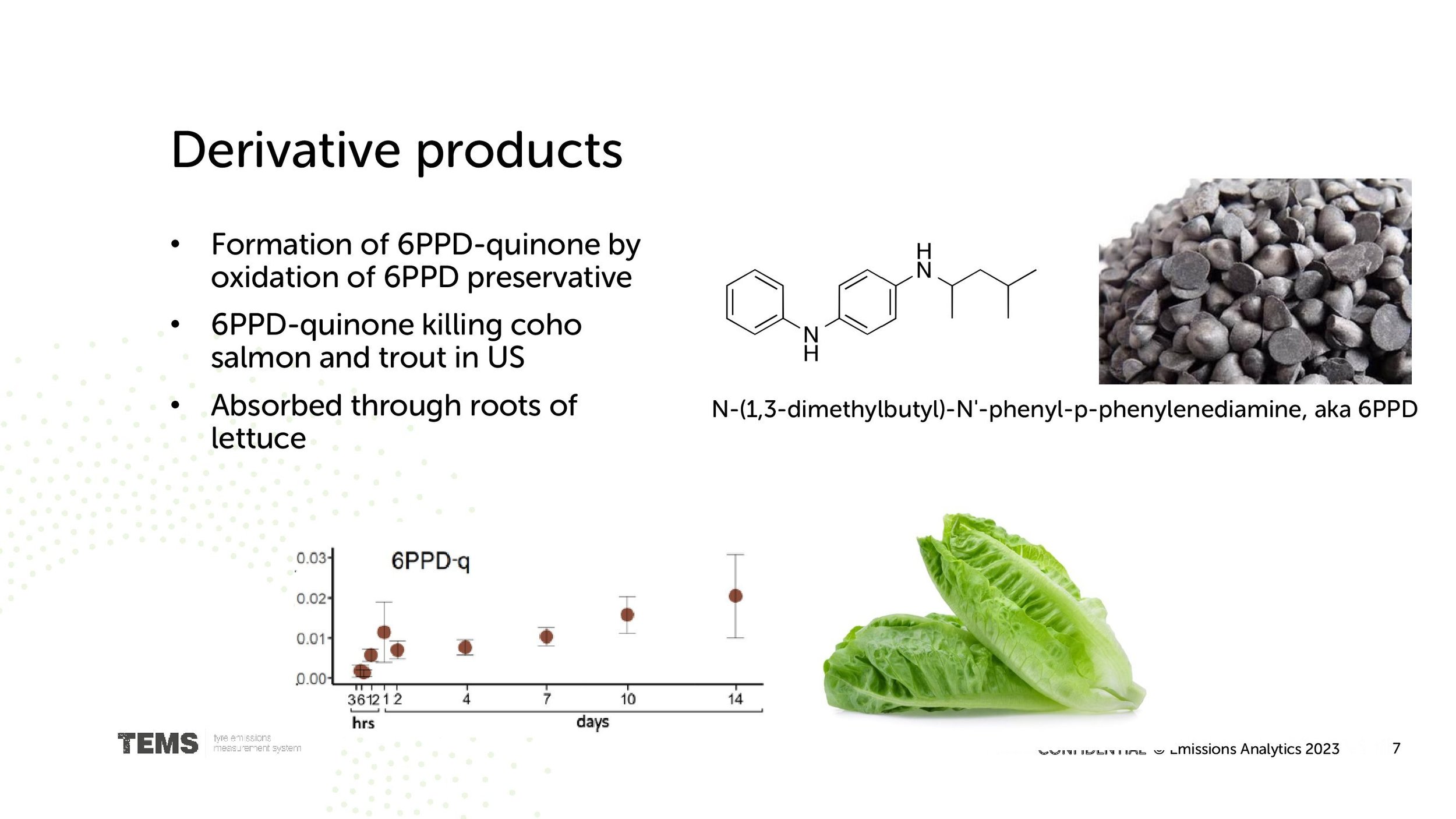

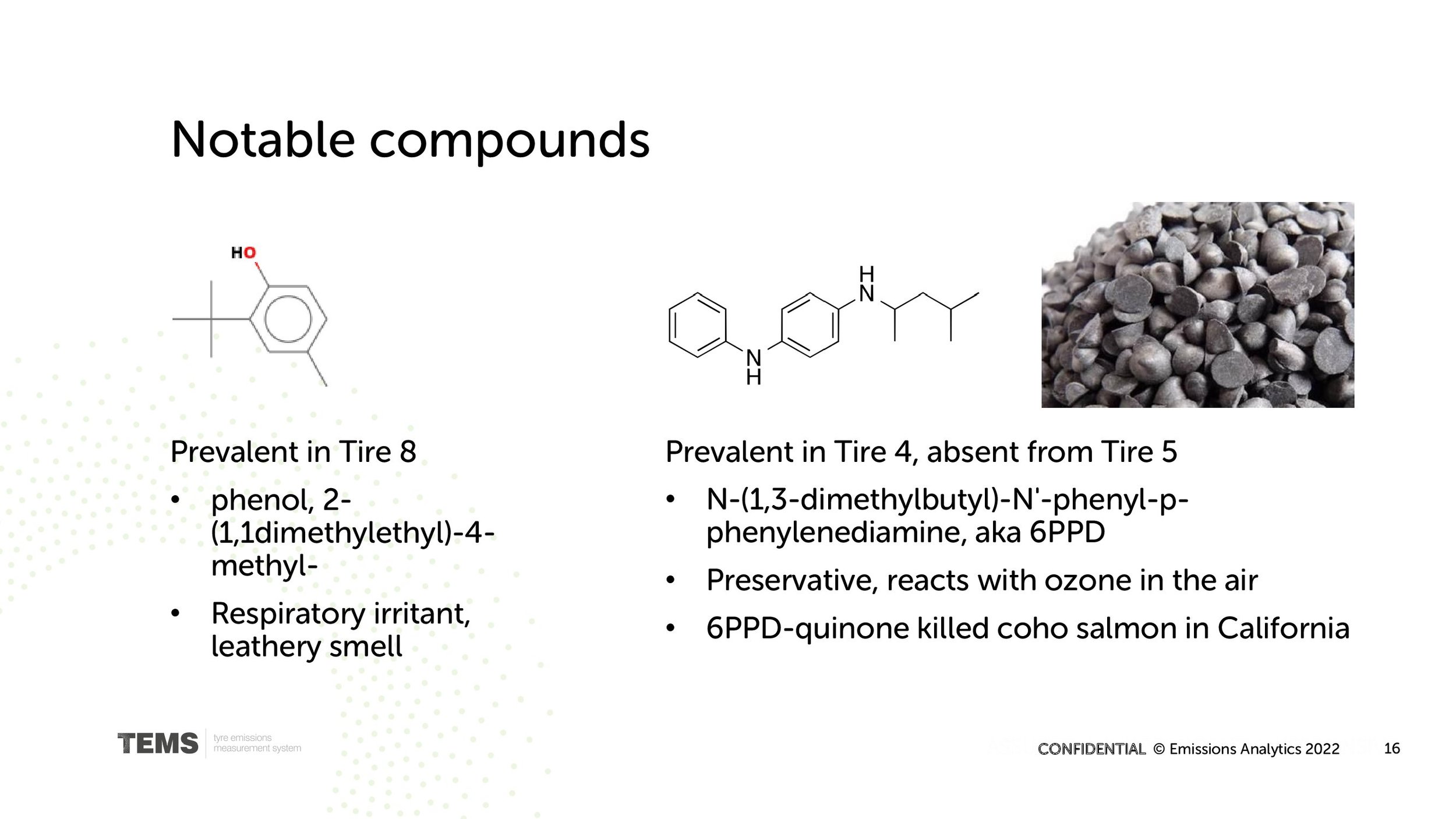

Recent peer-reviewed scientific research estimated that a median adult excretes 11.8 nanograms per kilogram of bodyweight of 6PPD and 6PPD-quinone in urine per day. These chemicals have been made famous by ground-breaking research on the West Coast of the US, which linked them to mass fatalities of coho salmon – and more recently various types of trout. 6PPD is a preservative present in almost all tyres and few other products, which forms 6PPD-quinone when it reacts with oxygen in the air, and this is the chemical that kills the fish. We covered this in an earlier newsletter. Now, the data on human urine from South China, which is soon to be published, strongly suggests that when we emit, we pass tyre emissions.

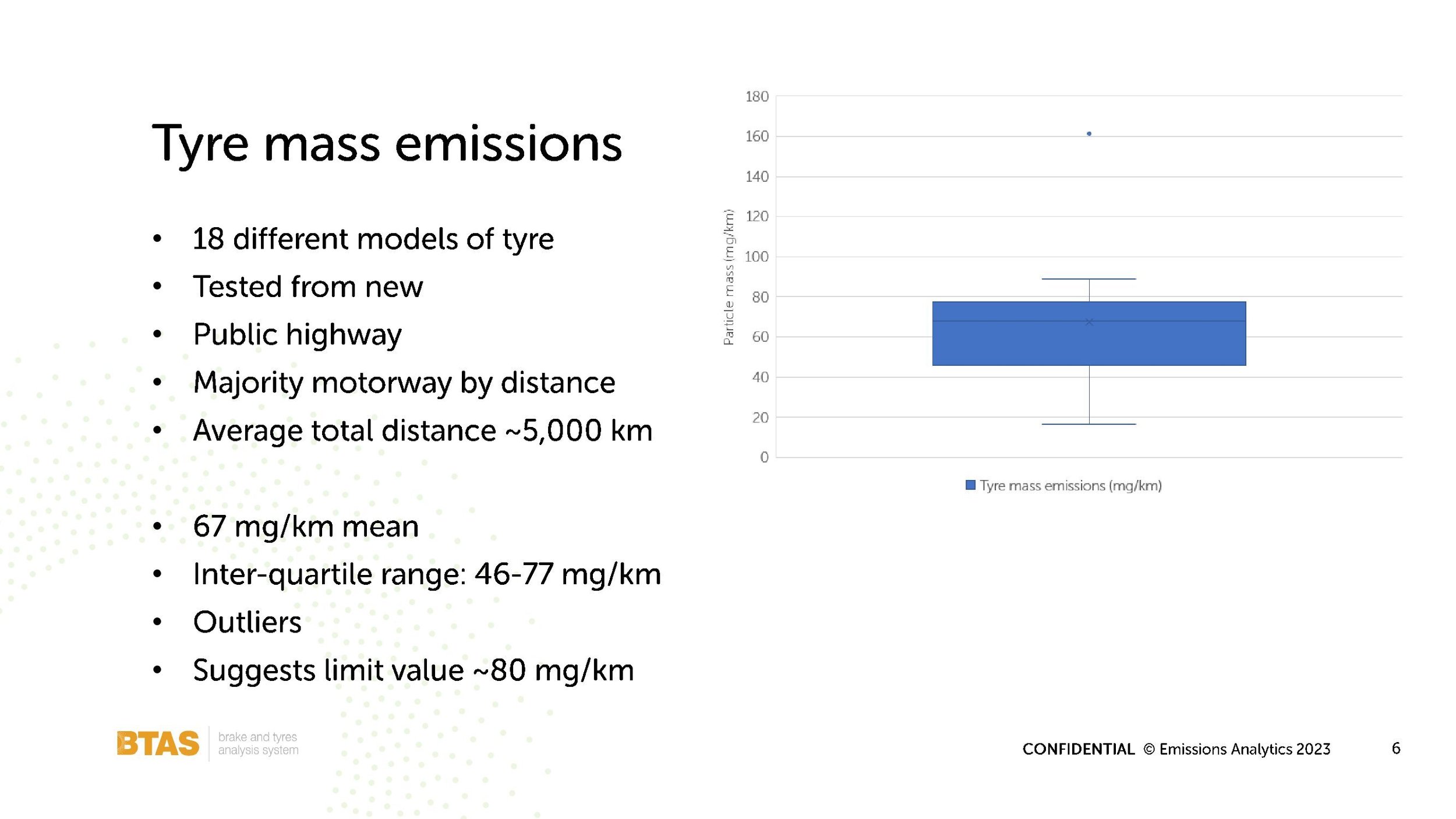

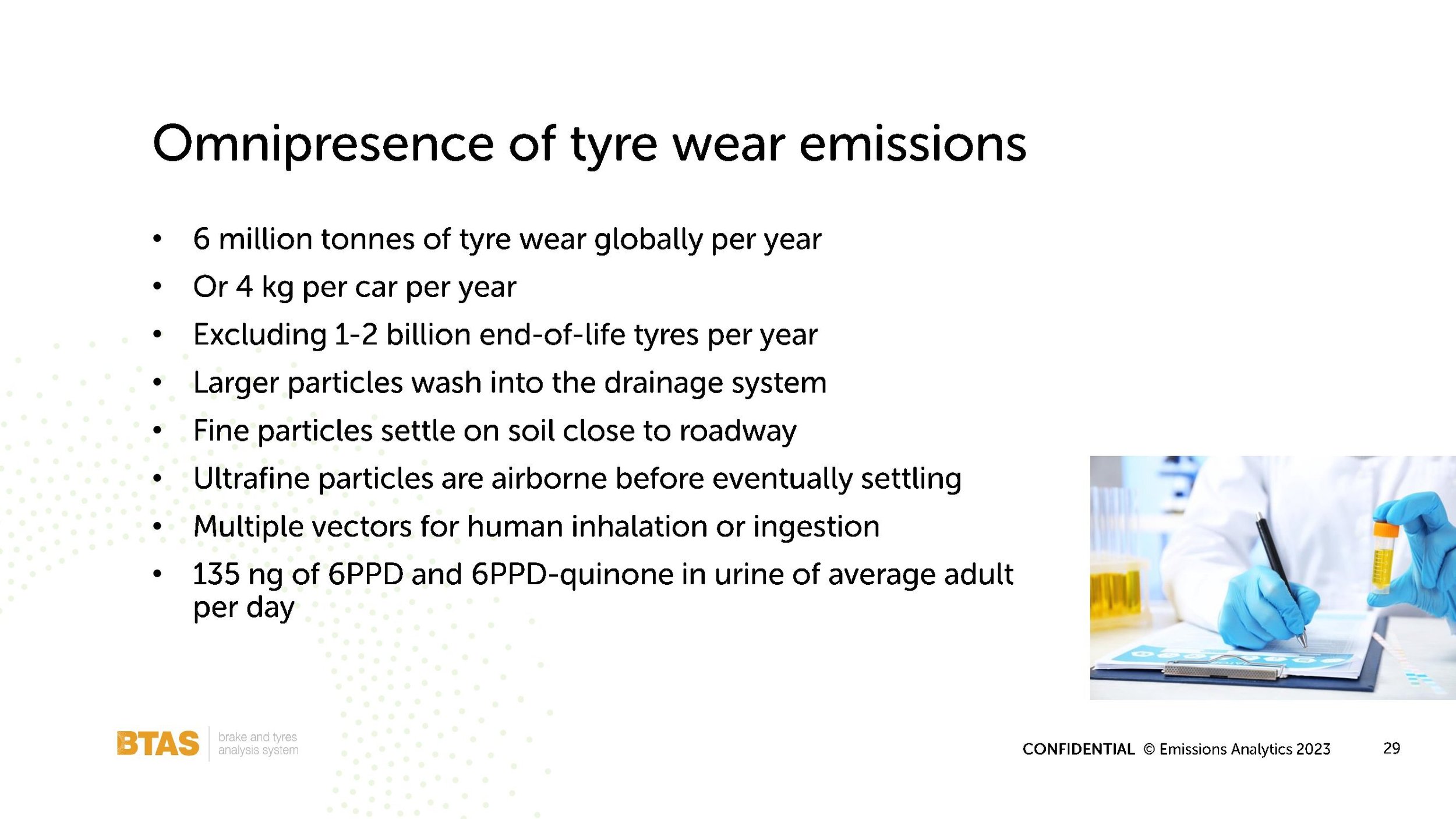

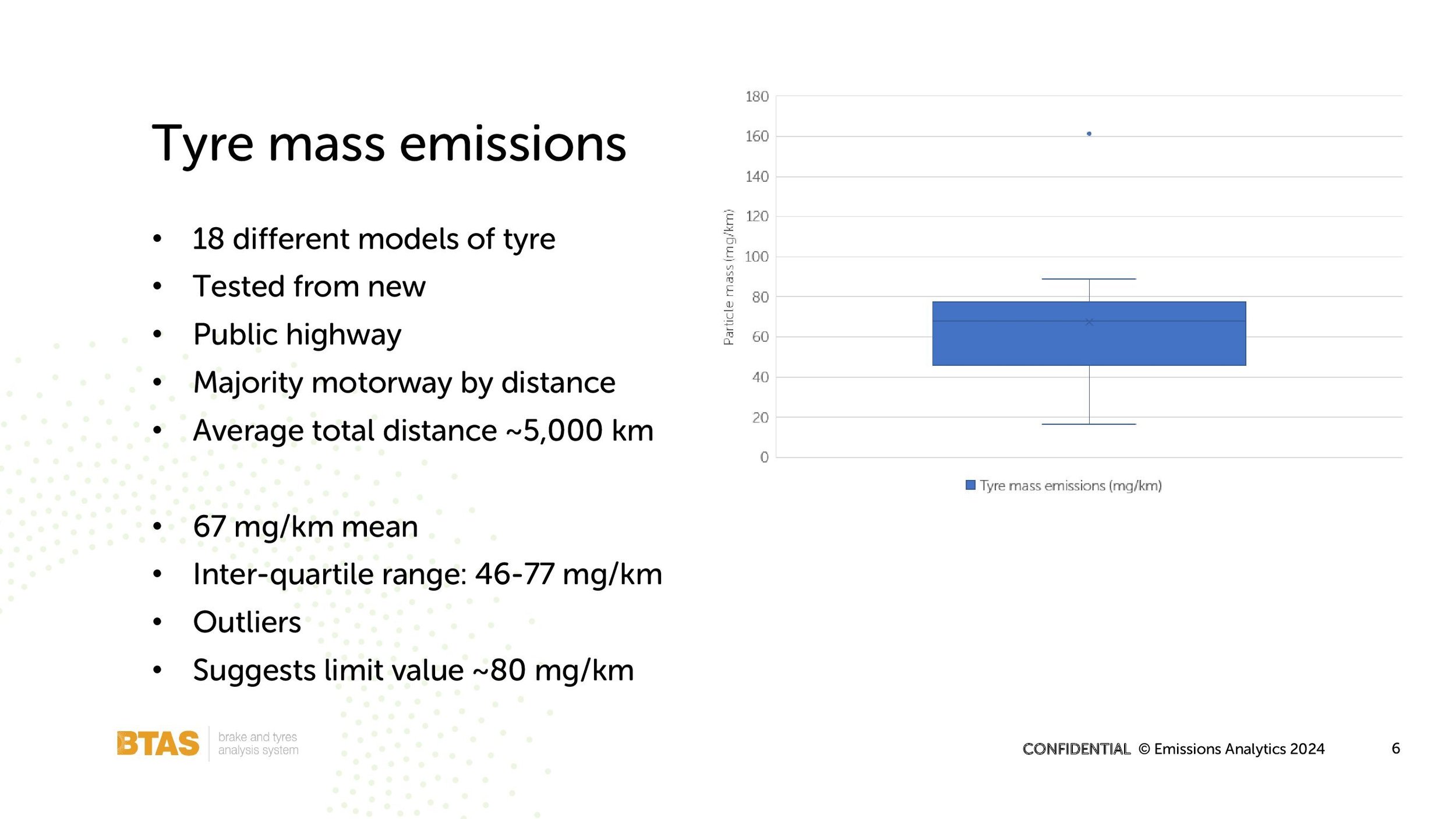

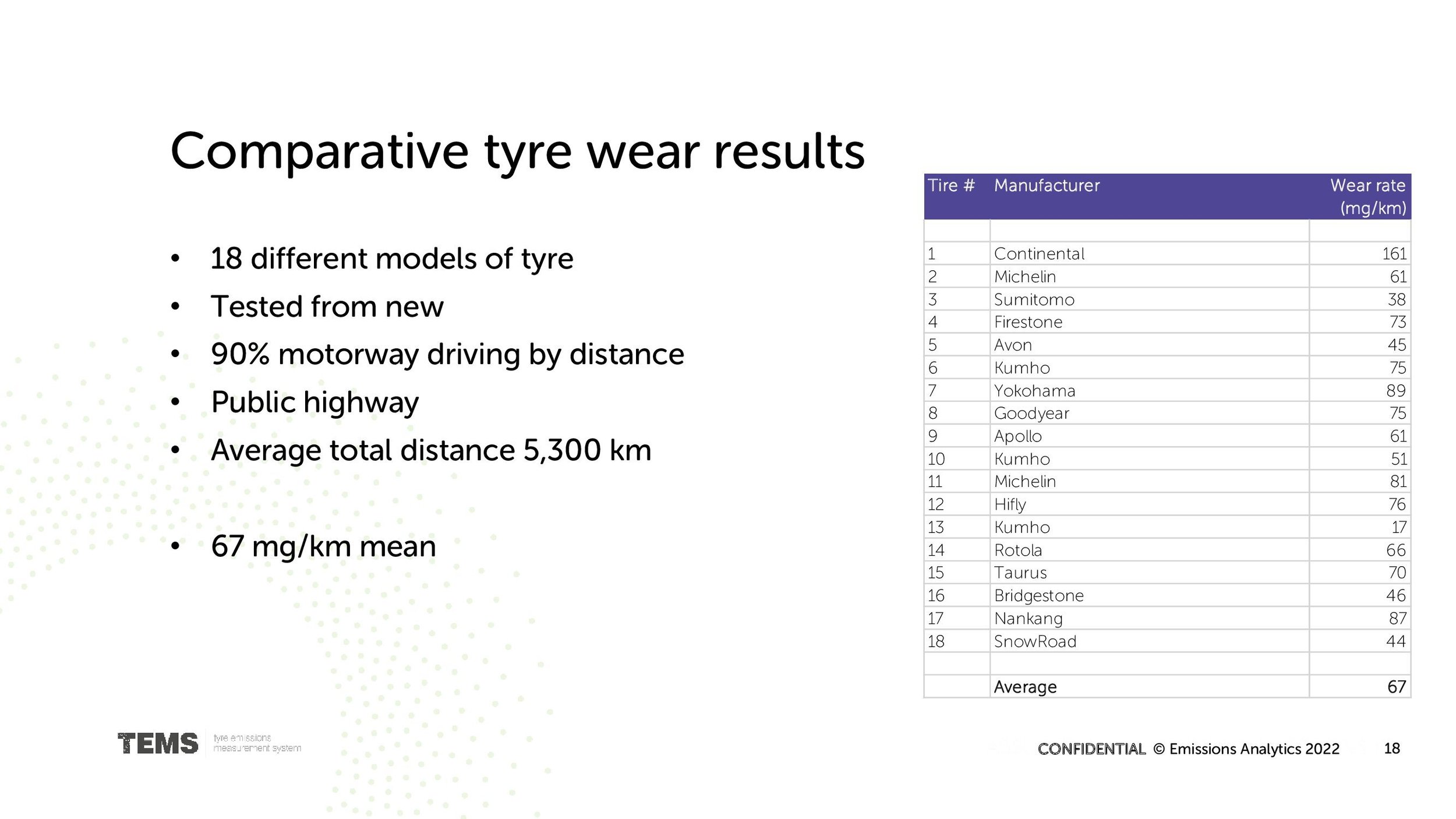

Emissions Analytics has been testing for the rate of tyre wear emissions in real-world conditions over a number of years, across thousands of miles on many different types of tyre. The current average wear rate for a whole vehicle is 67 mg/km from new tyres, and this is predicted to halve over the tyres’ lifetime. Therefore, particulate mass generated from tyre wear is nearly 2,000 times greater than that from the tailpipe of modern ICE vehicles, as previously reported. In addition, our testing suggests for every 500 kg extra vehicle weight – about the mass of a large battery – tyre wear emissions rise by 21%. By some, this has been interpreted as an attack on BEVs, as they are heavier. While it is true that this comprehensively disproves the notion – bizarrely incorporated in legal statute in many countries – that BEVs are zero emission, a better interpretation is that all tyre emissions are high compared to the tailpipe particle mass from the latest ICE vehicles. To complete the picture, it should also be recognised that tyre and tailpipe emissions approach parity when the comparator is an older diesel vehicle with no particulate filter installed, or on a vehicle with a compromised filter.

Therefore, we should not call the tyre emissions issue exclusively a BEV problem. The trend towards heavier ICE sports utility vehicles has been a contributor to these growing emissions rates as well. In fact, having now tested over 300 different tyre models for their chemical composition from around the world, there is an emerging picture that specialist BEV tyres designed to handle the greater weight and torque of the vehicle may contain fewer potentially toxic compounds. So, the wear rates may well remain high if the driver is using the available torque, but in terms of environmental damage this may be offset by better formulations. This mitigation does tend to come at a higher purchase price, however. It does further mean that, if a BEV is equipped with non-specialist tyres – most likely when the owner replaces the original manufacturer tyres – the emissions could be higher in both wear and potential toxicity. We will present further results on these innovative formulations in a later newsletter.

This analysis makes it clear that tyre wear emissions are being generated when any of the world’s 1.5 billion cars are driven. Latest estimates suggest they shed about 6 million tonnes of tyre material per year, or 4 kg per car per year. It is often suggested, however, that this is not a big problem, because the particles shed tend to be larger and get caught in storm drains and filtered out, or sit harmlessly by the roadside. There are many reasons to doubt this. First, in many countries, the particles are filtered out from storm drains and road run-off, but the resulting sludge is then sold back to farmers for fertiliser. Another undesirable form of circular economy.

By our estimates, around 10% of the total tyre particulate matter is airborne – primarily the ultrafine particles – but a majority is often said to settle on the land. Recent peer-reviewed scientific research from Casten et al in Environmental Science & Technology studied the uptake, metabolism and accumulation of tyre wear particles and derived compounds in lettuce. It found that 6PPD and 6PPD-quinone – among other compounds – were “…readily taken up by lettuce…” via the roots and then translocated to the leaves in a way that “…may be of concern to consumers.” The paper describes how tyre wear particles may leach derivative compounds even before entering the soil, but that “…the majority of compounds are expected to be released once TWP [tyre wear particles] enter the agricultural soils and come in contact with soil pore water.” This provides a challenge to potential regulation to understand derivative chemicals and their toxicity, as well as the original particles.

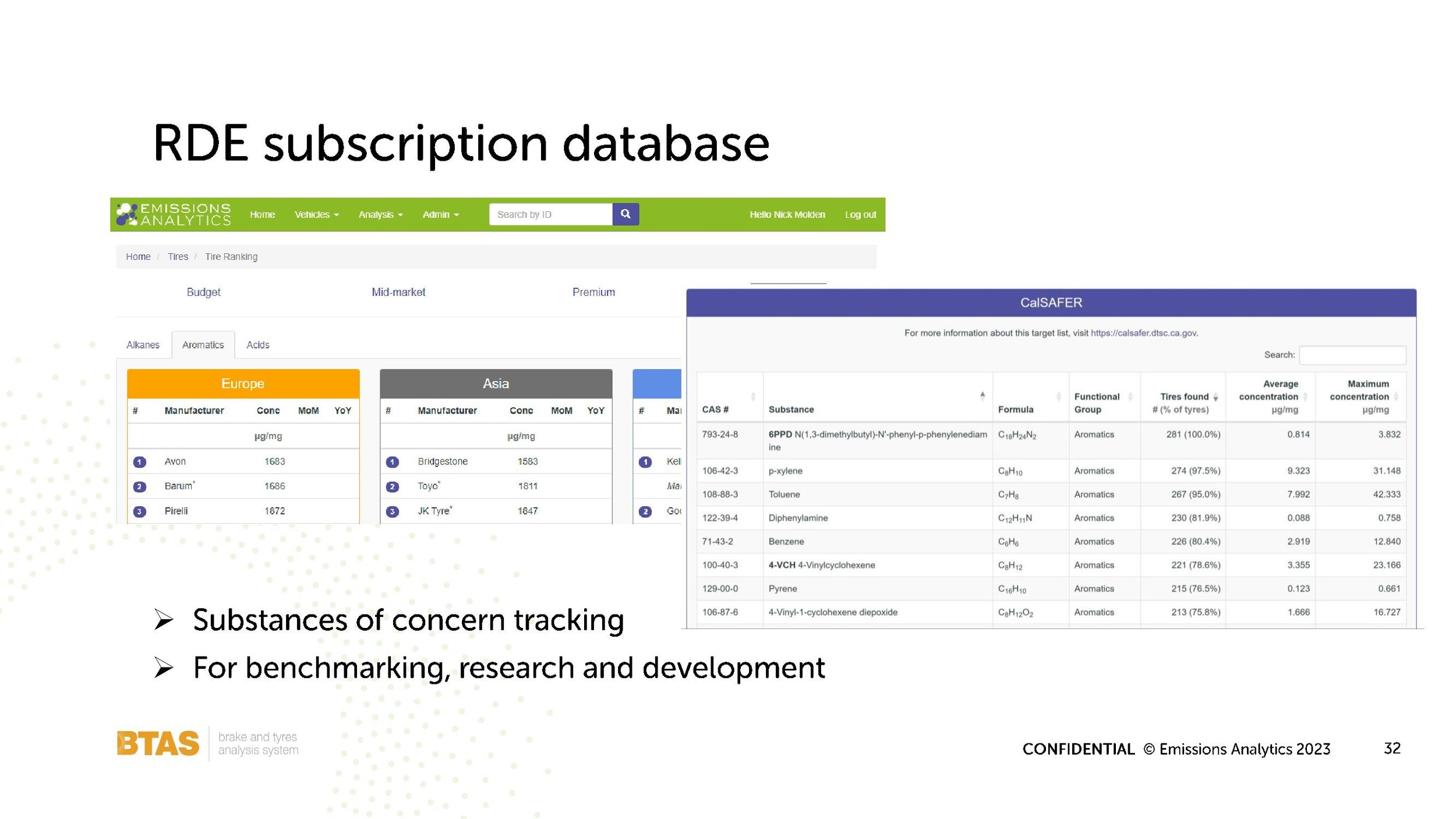

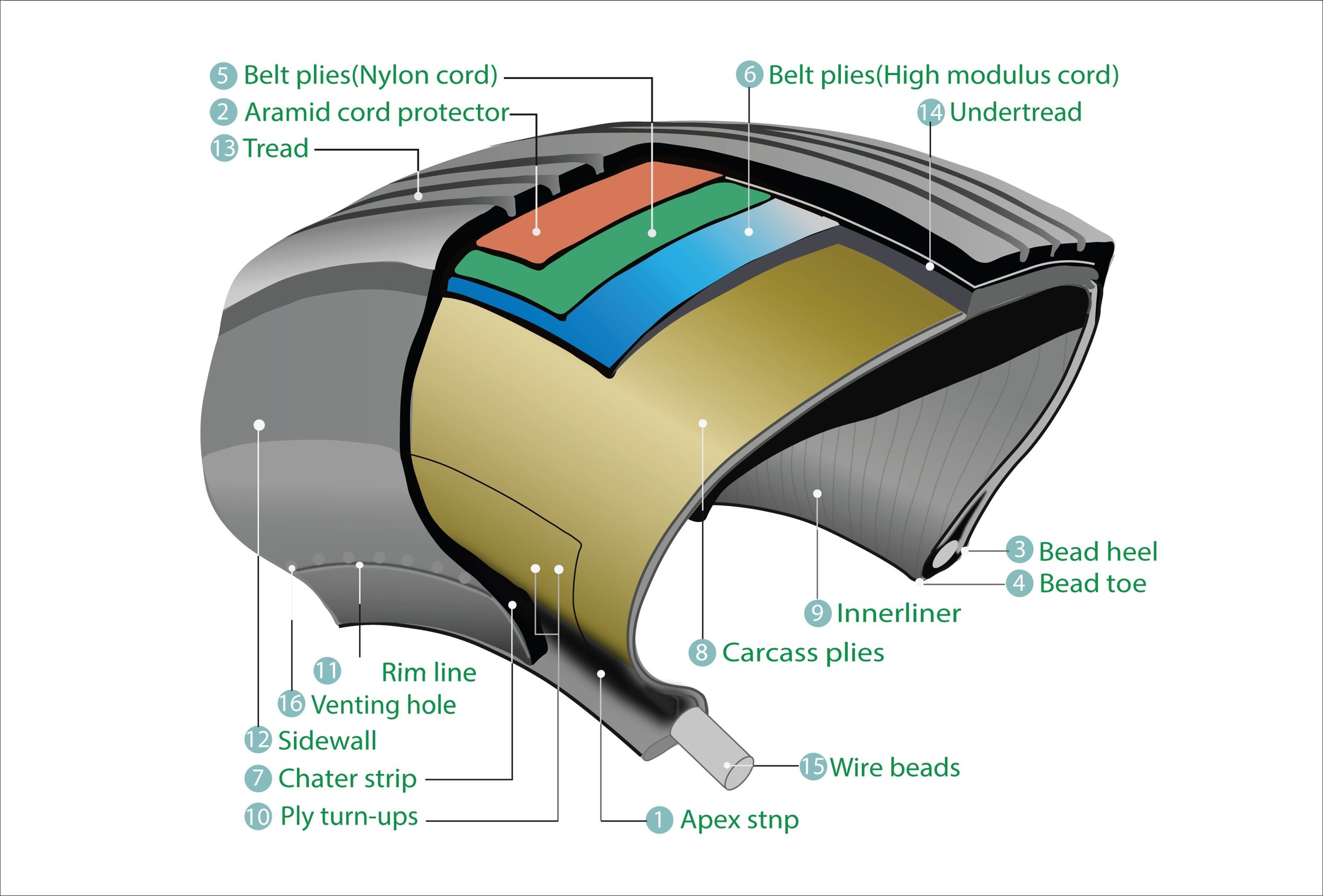

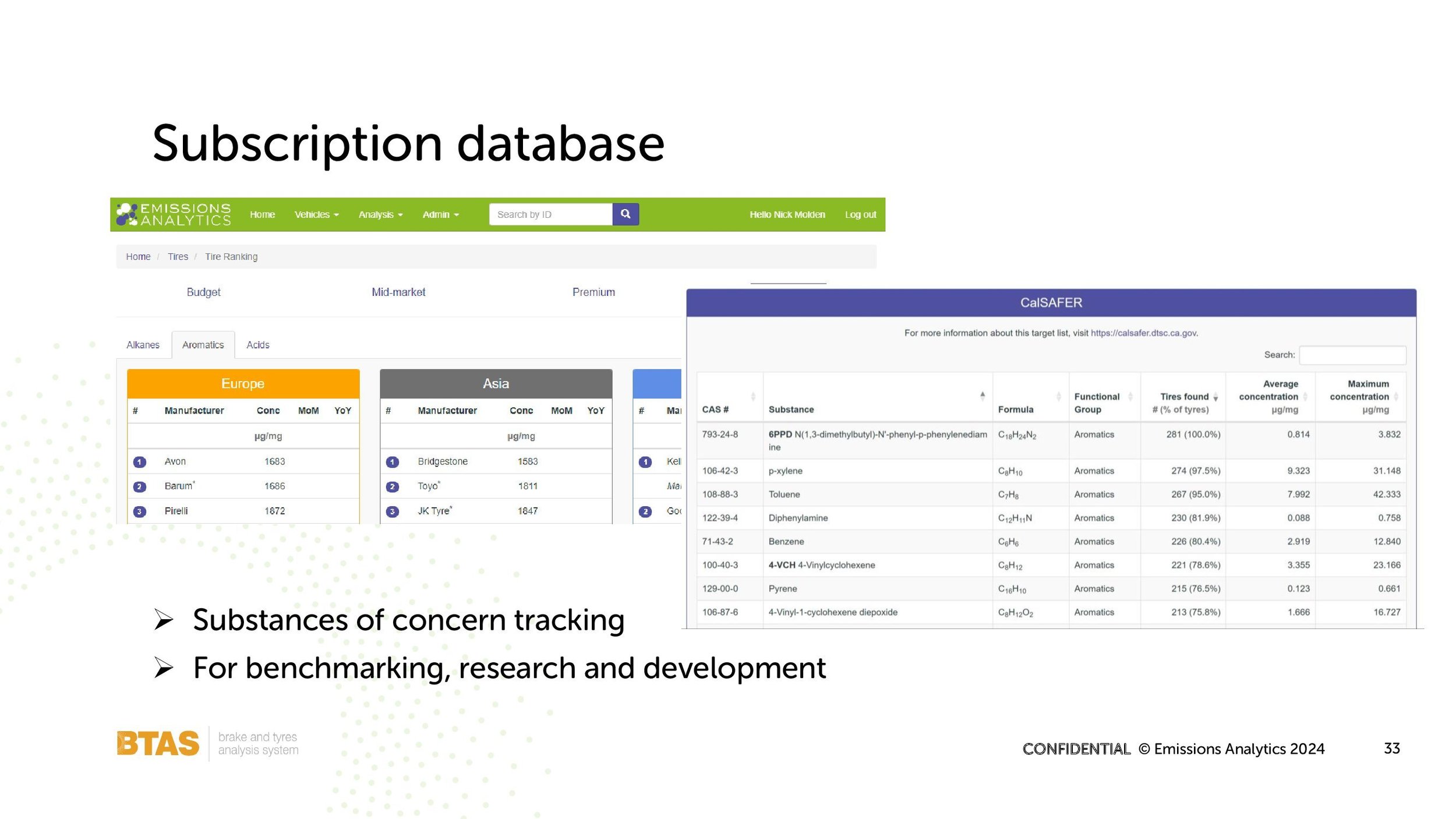

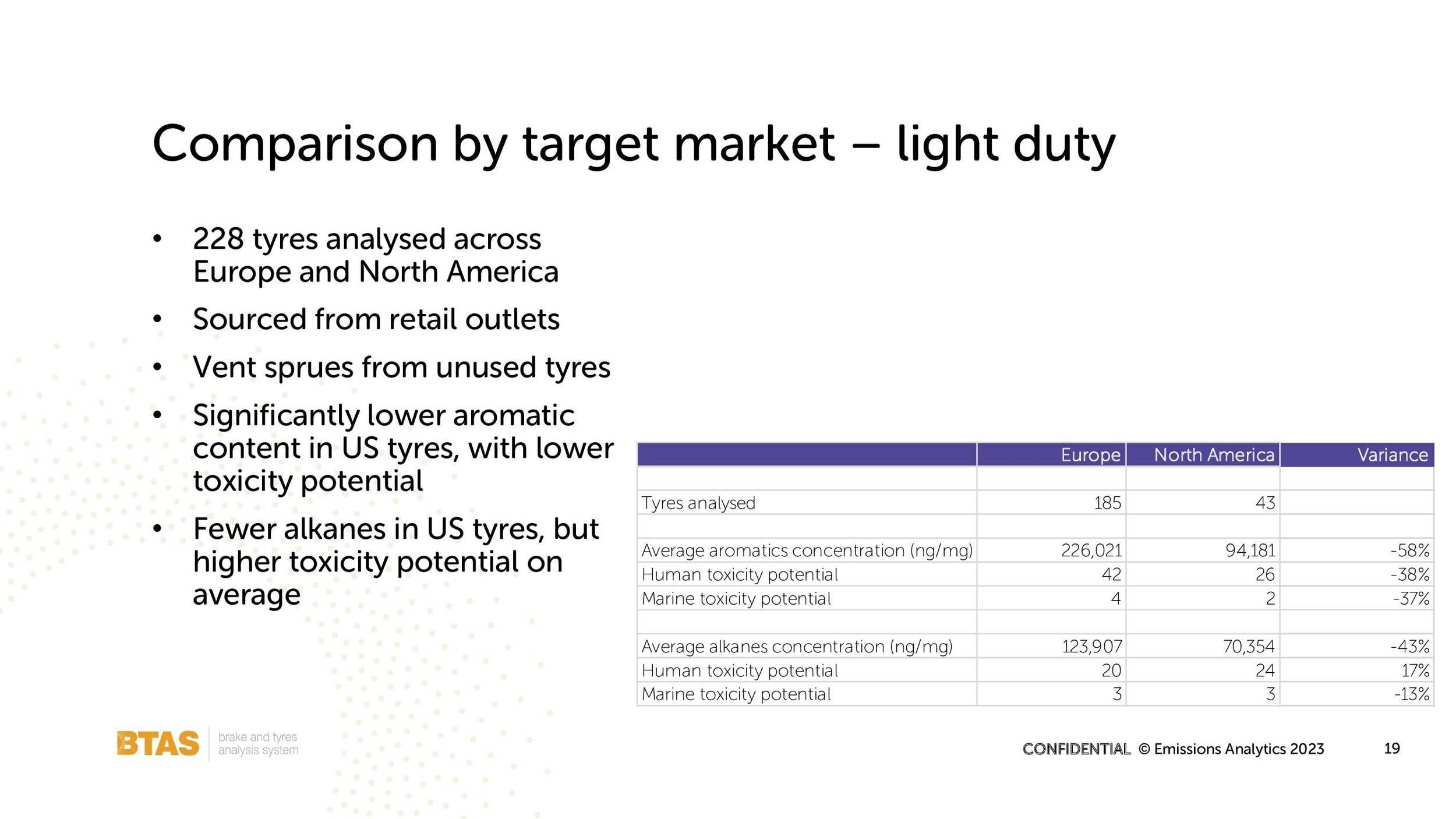

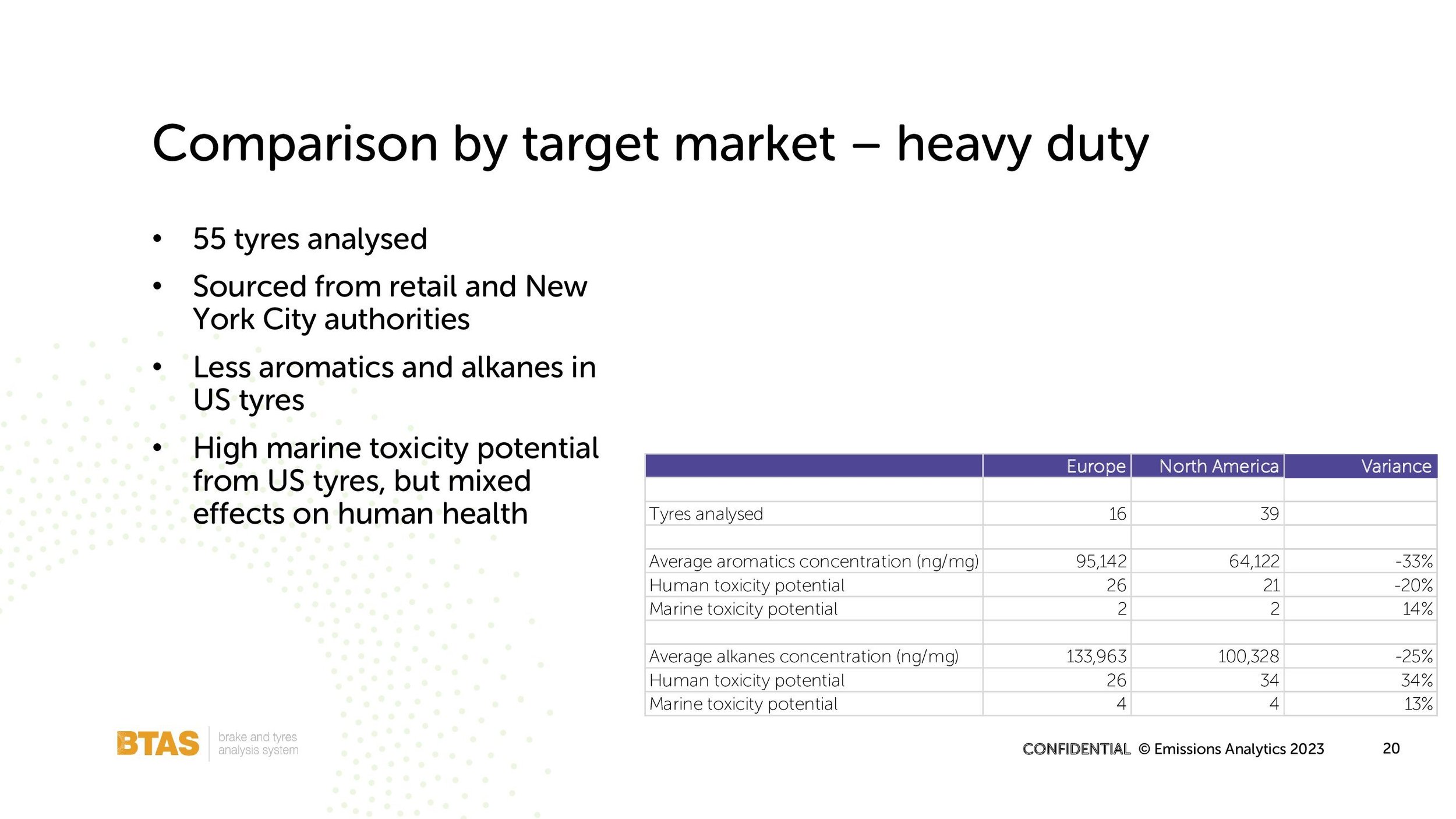

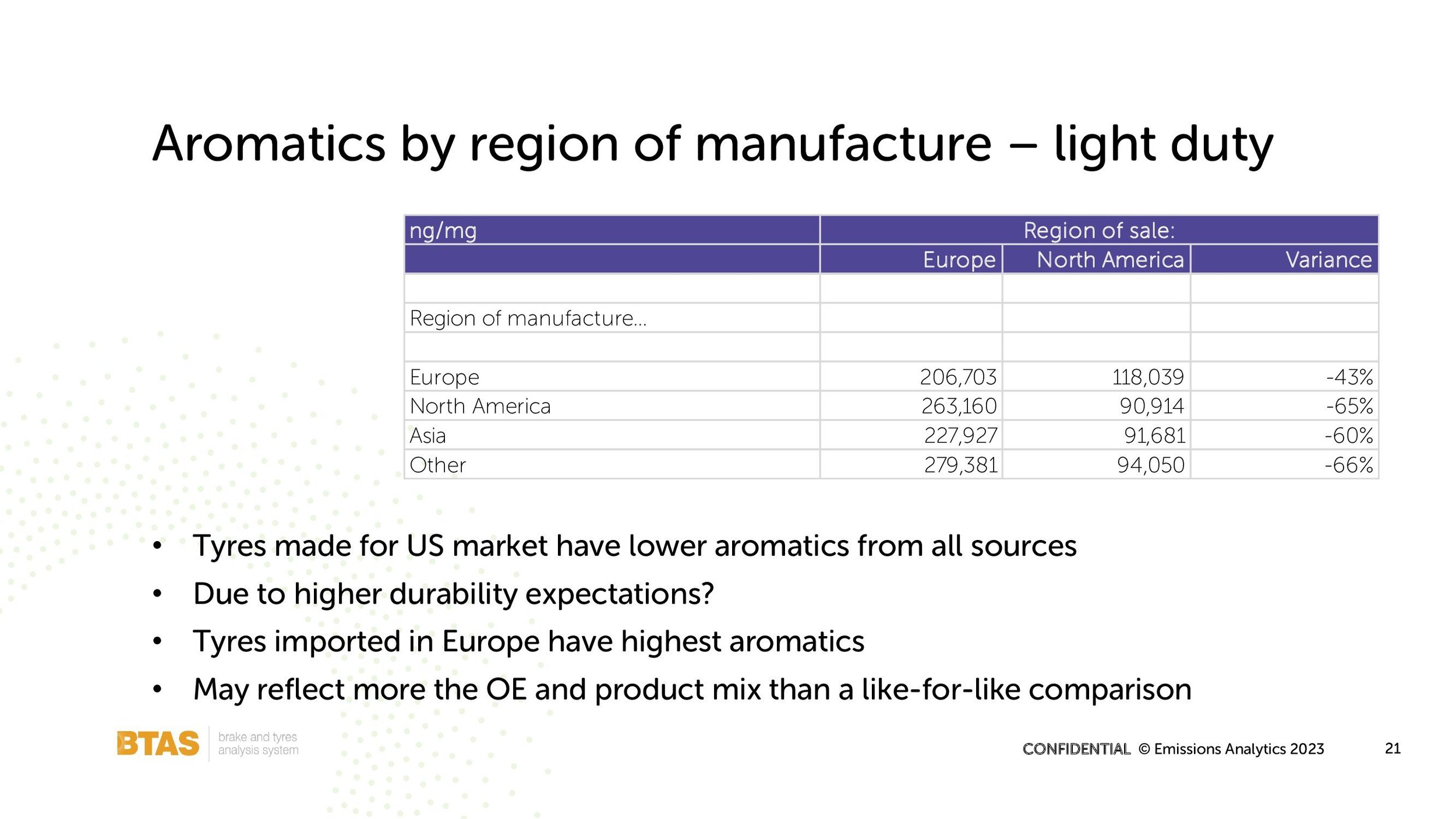

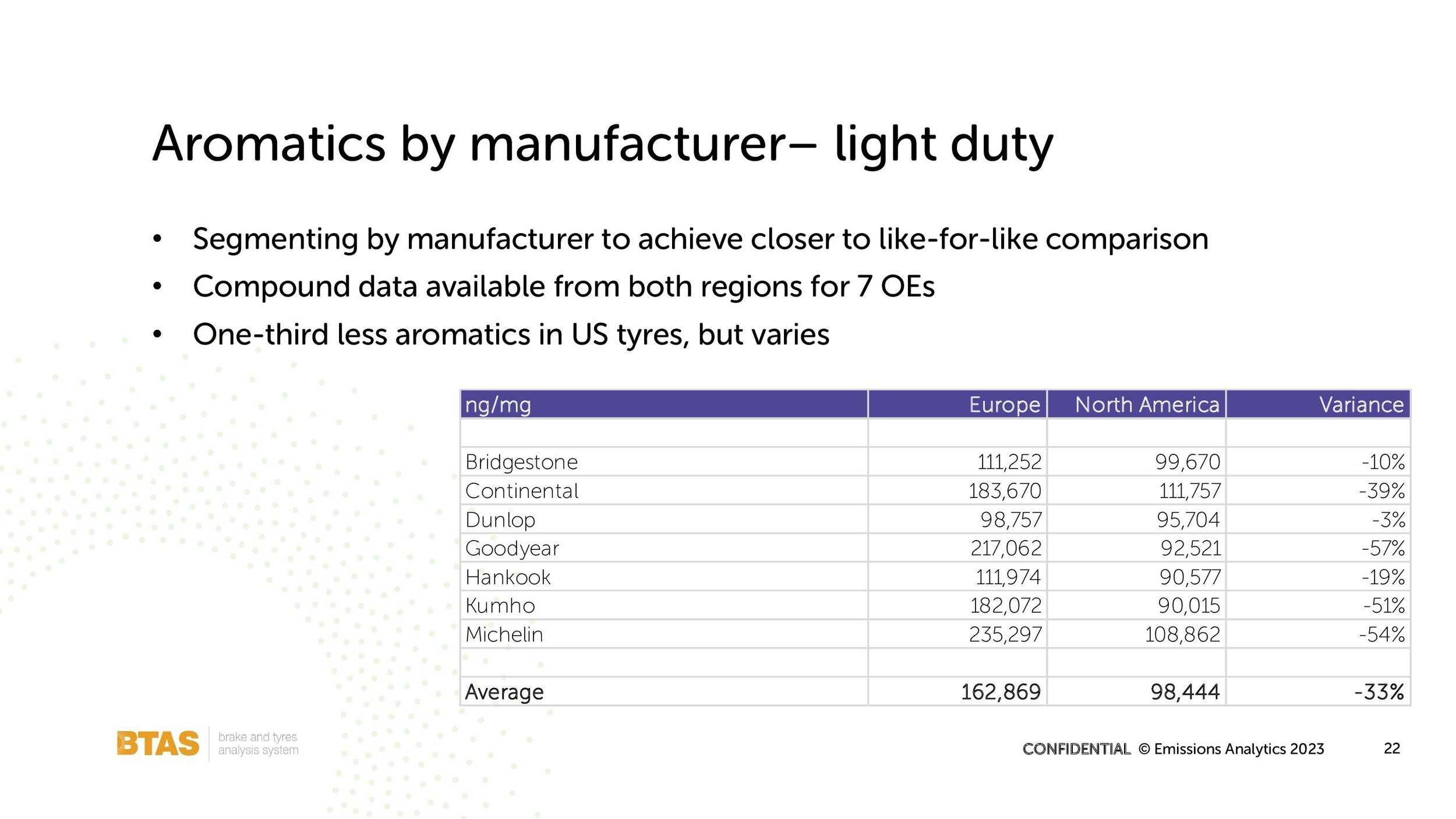

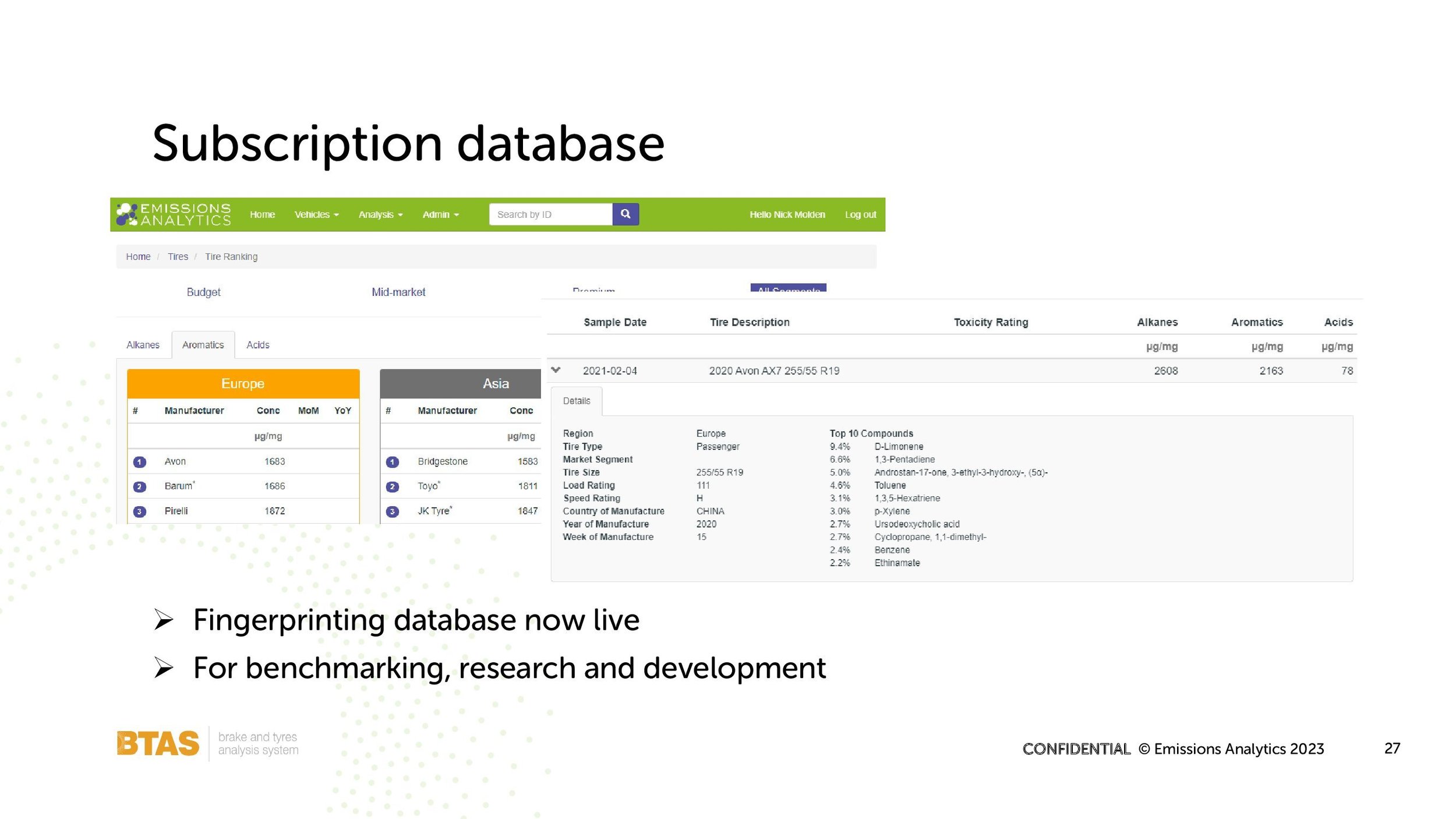

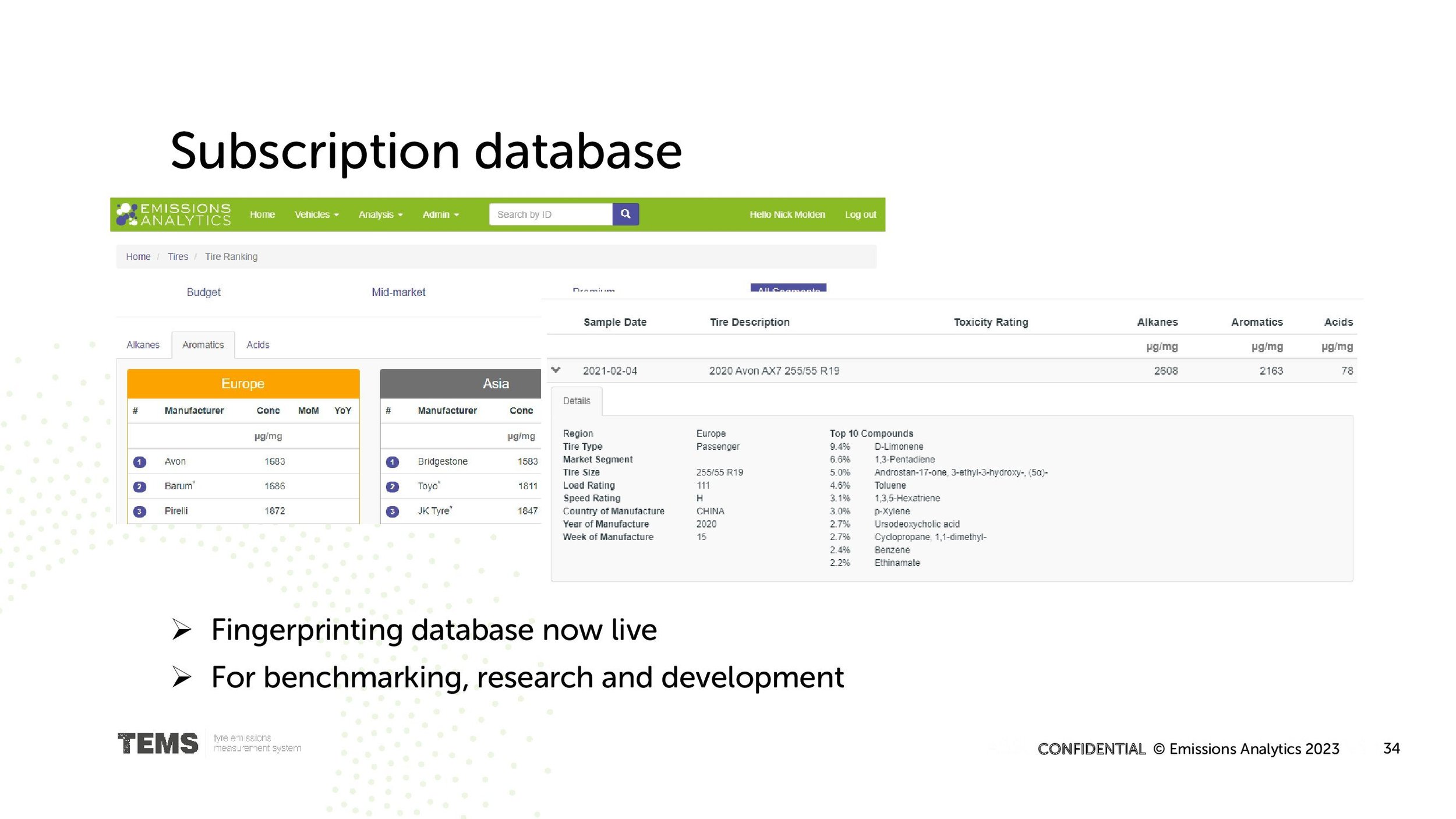

Fortunately, to aid this process, Emissions Analytics’ test programme aimed at mapping the chemical composition and leaching potential from tyre wear is progressing apace. Our subscription database has recently been expanded to add over one hundred tyre models from the US market – across light- and heavy-duty vehicles – to add to the hundreds of samples from the European market. The results help confirm one finding: that tyres are extremely complex and sophisticated in their construction. While this is impressive from an industrial and technology point of view, it helps create the problem set out at the start of this newsletter: the complexity helps camouflage their presence all around us in the environment.

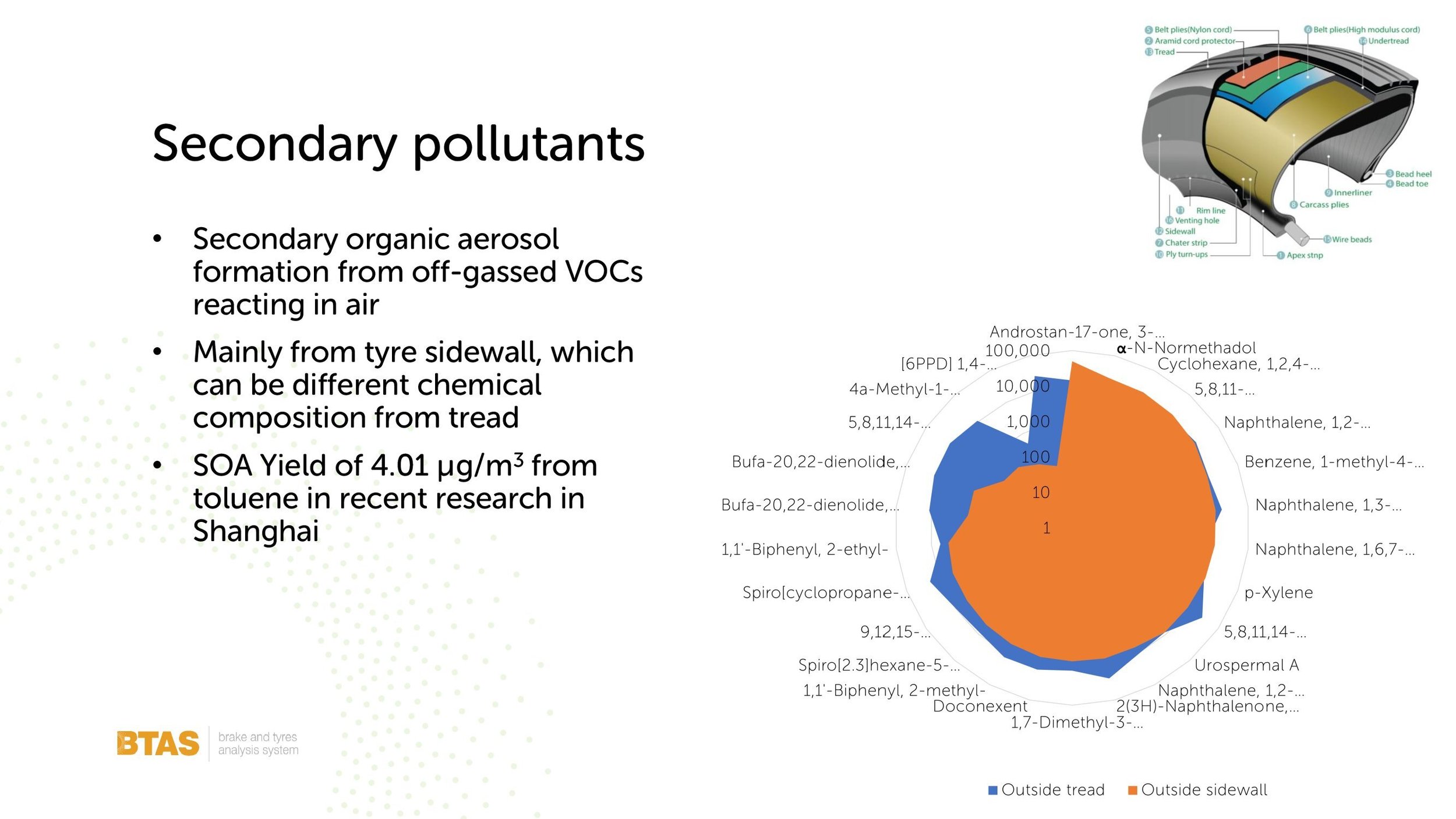

To illustrate this, we took one high-selling tyre from a major European manufacturer and took samples from five different locations: inside and outside tread, the centre band around the middle circumference, and the inside and outside sidewalls. It was expected that the inside and outside tread composition should be similar, as only some performance tyres have asymmetric construction – this was indeed the case for the tyre tested. The centre band was expected to be different as it needs properties including conductivity, although the differences were relatively small and specific.

But what of the comparison between the outside tread and outside sidewall? The tread primarily has exposure to the physical stresses caused by driving, while the sidewall helps maintain the structural integrity while being exposed to sunlight much of the time. The chart below shows the 25 most prevalent organic compounds found – using our specialist two-dimensional gas chromatography and time-of-flight mass spectrometry method – plus 6PPD. The average number of compounds found was 350 per sample. The scale is in nanograms of compounds per milligram of tyre sample, expressed logarithmically. The coloured areas represent the tread and sidewall respectively.

This shows that the sidewall has higher concentrations of certain chemicals, not least androstan-17-one‚ 3-ethyl-3-hydroxy-‚ (5α)-, which is a chemical found naturally in nutgrass, and lends certain properties to the tyre. It is also higher in naphthalene‚ 1‚6‚7-trimethyl-, which is part of the naphthalene group and known to be harmful if swallowed and very toxic to aquatic life at certain concentrations, with potentially long-lasting effects. The tread has higher concentrations of other chemicals, for which many have little or no toxicological information available. An exception is 1‚1'-Biphenyl‚ 2-methyl-, which is a known skin irritant, can cause eye damage, and affect the respiratory tract. Perhaps surprising, the concentration of 6PPD was higher in the tread than the sidewall, despite the sidewall being more exposed to sunlight.

These chemicals are all important to understand, and they can affect the environment in multiple ways. The tyre gets abraded, and the resulting particles can get inhaled or ingested by humans. As they settle on soil they can enter the food chain, as can particles that enter the waterways and either end up as drinking water for humans or inside fish and other animals then eaten by humans. Chemicals on the surface of the tyre can also react with the air or other chemicals to produce derivative products with toxicological effects, as with 6PPD leading to 6PPD-quinone. Such reactions can also lead to the formation of secondary organic aerosols, i.e. more particles. All along, chemicals originally bound up in the tyre particles may leach out at different rates and with different effects.

We conclude from this that, while different parts of the tyre have different chemical compositions, reflecting their different roles, many of the compounds are common. We are now able to identify both these common compounds and the differentiating compounds, which makes possible wider, targeted environmental monitoring to understand the sources and ultimate fate of tyre emissions. It also opens up paths to reducing the environmental impact, such as the California Environmental Protection Agency’s proposed targeting of 6PPD, which will force tyre manufacturers to consider alternatives. It is the assessment of the properties of the alternatives which will be important, to ensure we don’t switch one problem for another.

So, as you drizzle your salad with some tasty, oily dressing, you now know that the lettuce itself may be carrying various compounds that originated from the crude oil used to make the tyres, that wore as you drove to work, and that settled on the neighbouring farmer’s field. These chemicals are all around us, and inside us.

At least, however, we now know what to look for and can measure them out in the real world. Their camouflage is blown.

The circular economy

Reusing, recycling, repairing and sharing are defining hallmarks of a circular economy idea that is being promoted worldwide, but especially in Europe.

Zero-emission vehicles are zero-emission because they are

Reusing, recycling, repairing and sharing are defining hallmarks of a circular economy idea that is being promoted worldwide, but especially in Europe. It is not surprising that Europe leads the way, not through altruism, but for good economic reasons, as many key materials for a growing economy become scarce or expensive. Europe lacks deposits of many of them, but also makes it uneconomic to extract or refine them for industrial use.

But while resource reuse is logically and economically plausible, other aspects of environmental policy are circular in a less attractive way. Especially since Dieselgate, arguments between different shades of opinion as to the future of battery electric vehicles (BEVs) and internal combustion engines (ICEs) have become so raw, antagonised by ad hominem attacks. Yet, there are rarely disagreements between the sides on the underlying facts

Everyone knows that carbon dioxide (CO2) emissions are affecting the climate;

And that no vehicle is truly zero emission;

That BEVs are highly energy efficient, but batteries have low energy density;

That ICEs have poor efficiency, but compensate with high energy density fuels;

That BEVs reduce lifetime CO2 by ~50%, but this varies greatly by location;

That full, non-plug-in hybrids reduce CO2 by up to 30%, but that isn’t enough;

That battery and motor materials are scarce and often located in risky places;

That processing materials take lots of energy and creates local pollution;

That renewable electricity is mostly intermittent, increasing its real cost; and

That all vehicles create pollution, whether tyre wear or in their construction.

So, if there is a broad based of factual agreement, why the emotionalised debate?

We would propose that reason is that transport policy is suffering a bout of “a priorism.” This is typically defined as the systematic refusal to count anything as evidence against the truth of a purportedly empirical statement. Put another way, the argumentation for electrical vehicles is, like a green economy, circular. By defining BEVs as zero-emission in the European fleet average carbon dioxide (CO2) regulations, the answer is being assumed in the question. Therefore, BEVs cannot – despite any evidence to the contrary – be anything other than zero-emission. Even though, by common consent, they aren’t really.

It’s a form of cognitive dissonance – the mental anguish that arises when two beliefs contradict one another. BEV advocates know rationally that there are emissions from the manufacture of their vehicles, yet maintain that they are zero emission, because that is how the regulation defines them. Such internal conflict leads to anxiety and, from there, calm, rational discussion become difficult. As a psychiatrist explained: “If competing values, beliefs, attitudes, etc are not resolved or integrated, it greatly inhibits the ability of groups to have constructive dialogue, making it difficult, if not impossible, to arrive at a satisfactory compromise.” With the heavy emotional investment in beliefs on all sides, positions have become entrenched.

Why go on about this? Firstly, decarbonisation is an extremely important issue now, with global temperatures rising. Second, we need be sure that products that promise CO2 reduction do deliver in practice. Third, selfishly, Emissions Analytics aims to bring about a better understanding of real-world emissions through independent testing, to inform better policy and decision-making. While we are snagged on a logical fallacy, however, no amount of real-world testing is going to help move the debate forward. As Just Stop Oil protestors are literally stuck, we are stuck in an argumentative loop.

Defining BEVs as zero-emission was no accident by authorities. A further deliberate act has been not to designate other technologies such as renewable or synthetic fuels as zero-emission in any circumstances. Even if an innovative liquid fuel were created by green electricity and sequestering CO2 from the air, it would still create CO2 when burnt in the vehicle, and so would, officially, be as bad as the equivalent fossil fuel. By ignoring upstream emissions, BEVs get a double benefit: the upstream negative emissions of alternative fuels are ignored just as the upstream positive emissions of BEVs are.

To the argument that incorporating anything outside the official certification test in emissions targets is too difficult, consider the credit given to ‘eco-innovations’. Under the current European certification regime, eco-innovations are novel technologies that produce real-world CO2 reductions beyond what is measured on the certification cycle.

Each eco-innovation must prove its efficacy through a test programme, following technical guidelines from the European Commission. There are also various qualifying rules, such that the benefit should be at least 1 g/km, the technology should contribute only to the safety or performance rather than the comfort of the vehicle, and must not depend on driver behaviour. In short, the European Commission has designed and legislated for a system that complements the core CO2 targets, where real-world benefit can be proven. Under the eco-innovation rules, the maximum benefit a vehicle could be given was 7 g/km in its type approval CO2. Synthetic fuels, theoretically, could achieve up to 100% reduction in CO2, yet there is no equivalent system to recognise their value. The best we have so far is that the Commission has been mandated to prepare a report on the possibilities by 2026. These fuels are, it should be noted, being pushed through the renewable fuels directives, which does foster the industry to some extent, but it does not help manufacturers meet their fleet CO2 targets, so makes no difference to the incentives to produce and sell BEVs.

Therefore, we can conclude that the absence of a mechanism to credit or punish upstream emissions is a choice by governments and regulators. So long as this is the case, there is no technology that can compete with BEVs except hydrogen. In fact, a hydrogen fuel cell vehicle powered by ‘grey’ hydrogen – hydrogen created from natural gas using steam methane reformation without capturing the greenhouse gases made in the process – would be counted as zero-emission, while a synthetic fuel created with clean electricity and sequestering CO2 from the air would be as bad as a fossil fuel, despite the former being very dirty and the latter clean. This is clearly not an effective or honest route to maximum CO2 reduction, but that is the choice being made.

It is important to strike a note of caution about alternative fuels, however. Creating synthetic fuels is highly energy intensive and so cannot be scaled to make a sufficiently big difference until we have plentiful, cheap low-carbon electricity. Fuels made from renewable feedstocks such a used cooking oil to create replacement diesel such as hydrogenated vegetable oil (HVO) are subject to limited supply of the feedstock, as well as the conversion also requiring energy.

The optimal approach would be to offer an allowance for these fuels in the fleet-average targets, but subject to two important tests. First, provenance would need to be verified to make sure what was being sold was genuine – with the pressure on feedstocks, fraud is a real possibility. Second, the chemical composition of the feedstocks may lead to new or increased tailpipe emissions. This is where Emissions Analytics has been developing cutting-edge techniques using two-dimensional gas chromatography and time-of-flight mass spectrometry. This allows the almost complete chemical profiling of both the fuels and the exhaust gases produced.

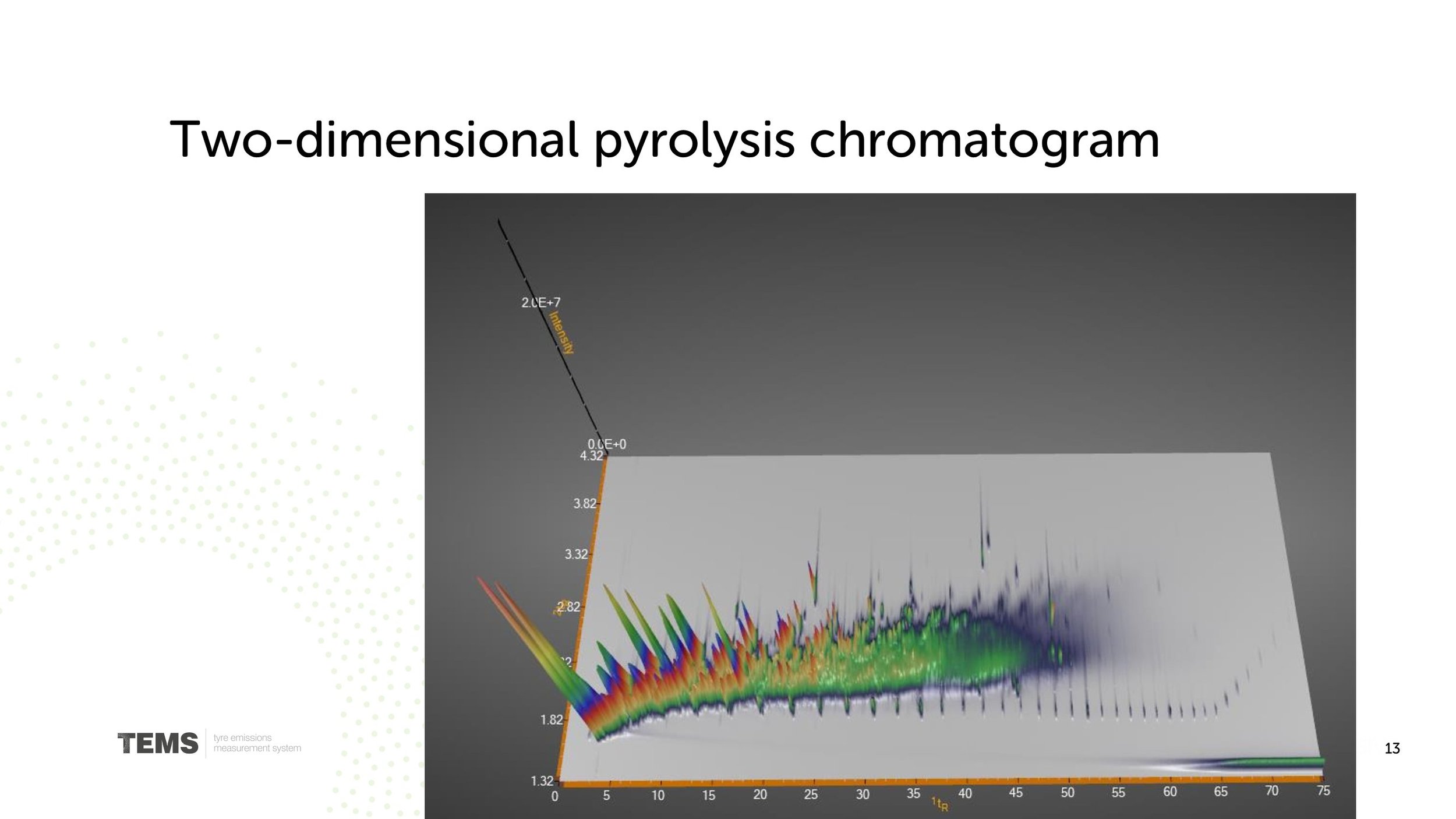

A fuel fingerprint is shown in the chromatogram above. In short, the plot depicts hundreds of distinct organic compounds, separated in two dimensions, approximately to the molecule size and electrical charge. The intensity of the colour represents the prevalence of the compound. Taking HVO, as an example, any fuel sample can be compared to a reference HVO fingerprint. In a recent project, four different HVO products were purchased in the marketplace and subjected to this fingerprinting. Three of these matched well, with an average of 342 organic compounds, of which just 0.1% were aromatics (often carcinogenic) and 0.8% oxygenated (containing oxygen atoms). One of the fuels deviated significantly, with 522 compounds, of which 13.2% were aromatics and 14% oxygenated. The dissonant sample was shown to match standard B7 diesel closely, which led to the conclusion that standard diesel with little or no HVO added was being passed off as HVO to customers.

Burnt in the engine, these fuels of different chemical composition may well lead to different exhaust emissions, and some of those emissions might not be regulated. For example, when E10 gasoline was introduced, the concern was that the oxygenates from the added ethanol would lead to more acetaldehyde emissions, which are not directly covered by the Euro regulations. Emissions Analytics’ on-road testing can measure individual species of volatile organic compounds (VOCs) at the tailpipe, for example its EQUA programme shows that the average formaldehyde emissions from standard diesel is 0.32 mg/km.

As this demonstrates, it is possible to validate the low-emission credentials of these fuels, and so there is no reason not to incorporate them into the CO2 target system and Euro 7 pollutant emissions limits. The latter would require only a small step beyond the current proposal in order specifically to target species such as formaldehyde and acetaldehyde from light-duty vehicles.

While the European Commission considers its 2026 renewable fuels report, BEVs will continue to enjoy a legislated advantage. In many respects they are excellent products: quiet torque and cheaper operation, especially for city dwellers. Their market share will likely continue to grow, and would probably even continue to grow without the current lavish subsidies, as some car buyers value them highly. They do not, however, suit many real-world needs, or suit them as well as ICE vehicles; and they are definitely not zero-emission, whether for lifecycle CO2 or tyre wear emissions. Yet, when governments perform their Net Zero calculus, there is only one powertrain realistically available as the solution. BEVs will always win. But that is not a surprise – the answer was in the question.

Until the question is corrected, we will continue to live in an anxiety-inducing state of cognitive dissonance. Maybe this suits certain interested parties, as the different sides slug it out, with no prospect of changing the result. But maybe a more effective, healthier, happier approach would be to consider properly the real-world emissions of the various decarbonisation options and to unleash competition and innovation. A corollary of that would be that we would realise that there are no zero-emission options currently, and there will never be until the grid is decarbonised and expanded. Instead, we could have a sensible discussion about accelerating wind, solar, nuclear and any other available, scalable alternatives, to clean the grid as soon as possible.

Until then, we can perhaps best summarise this situation by cannibalising Henry Ford’s statement that a customer, “…can have a car painted any colour that he [sic] wants so long as it is black.” So long as key materials are scarce and expensive and the electricity grid remains dirty in most places, a multi-lane, multi-technology, multi-fuel approach would be more robust. We need every conceivable innovation to reduce greenhouse gas emissions. But what the current fleet targets mean is that you can have any car you like, as long as it’s fully electric.

Following the tyre tracks… Where do tyre emissions go?

We know, from earlier research, that tyres emit lots of particles, both coarser and the more potentially dangerous ultrafines. To put this in context, the levels are less than from exhausts of many older diesel vehicles without filters, but orders of magnitude greater than from the exhausts of modern internal combustion engine vehicles with the latest filters. But, where do these particles go, and can they be found in the environment?

We know, from earlier research, that tyres emit lots of particles, both coarser and the more potentially dangerous ultrafines. To put this in context, the levels are less than from exhausts of many older diesel vehicles without filters, but orders of magnitude greater than from the exhausts of modern internal combustion engine vehicles with the latest filters. But, where do these particles go, and can they be found in the environment?

As a consequence of the size distribution of particles in tyre wear, as set out in our earlier newsletter, it is reasonable to believe that the particles go to air, soil and water. Some tyre particles will be directly deposited on the road verge or in rivers near roads, but the smaller ones will settle further away after a period of time. The tyre particles contain on average over 400 organic compounds, plus a range of metals. Together, this makes for a complex product that is emitted into the environment in many different ways.

Compare this with tailpipe emissions. While there are many volatile organic compounds in exhaust fumes, the pollution is dominated by carbon dioxide (CO2) and nitrogen oxides in modern vehicles, with some carbon monoxide and ultrafine particles. Therefore, the environmental impact is dominated by a small number of compounds almost all of which are suspended in air for an extended period.

The differences between tyre and tailpipe emissions presents an interesting paradox: as tyres are more complex, they may leave a more easily identifiable fingerprint in the environment. If we take an air sample and observe some CO2, it is impossible to ascribe that to a source, whether vehicular or from human exhalation. Even with NOx, it is impossible to say whether that comes from a car, truck, home heating or an industrial source. In contrast, if we find some benzene‚ 1‚2‚4-trimethyl- in river water, for example, there is a fair chance it originated from tyres. Seeing multiple compounds in the environment that we know can come from tyres only increases that confidence. The very complex nature of tyres means such a fingerprint can be left. In contrast, for tailpipe emissions, we have to fall back on constructing ‘inventories’ – look-up tables containing average values – to characterise what emissions come from different types of vehicle, derived from testing those vehicles, and often combined with activity data.

Although it took many years of work, researchers in the US were eventually able to link the death of significant numbers of coho salmon, and latterly also trout, to the chemical preservative 6PPD in tyres. This was covered in our earlier newsletter, 'Fishy'. Therefore, it is complex, but possible, to determine the original source of pollutants or causes deleterious effects observed in the environment. How can this approach be generalised?

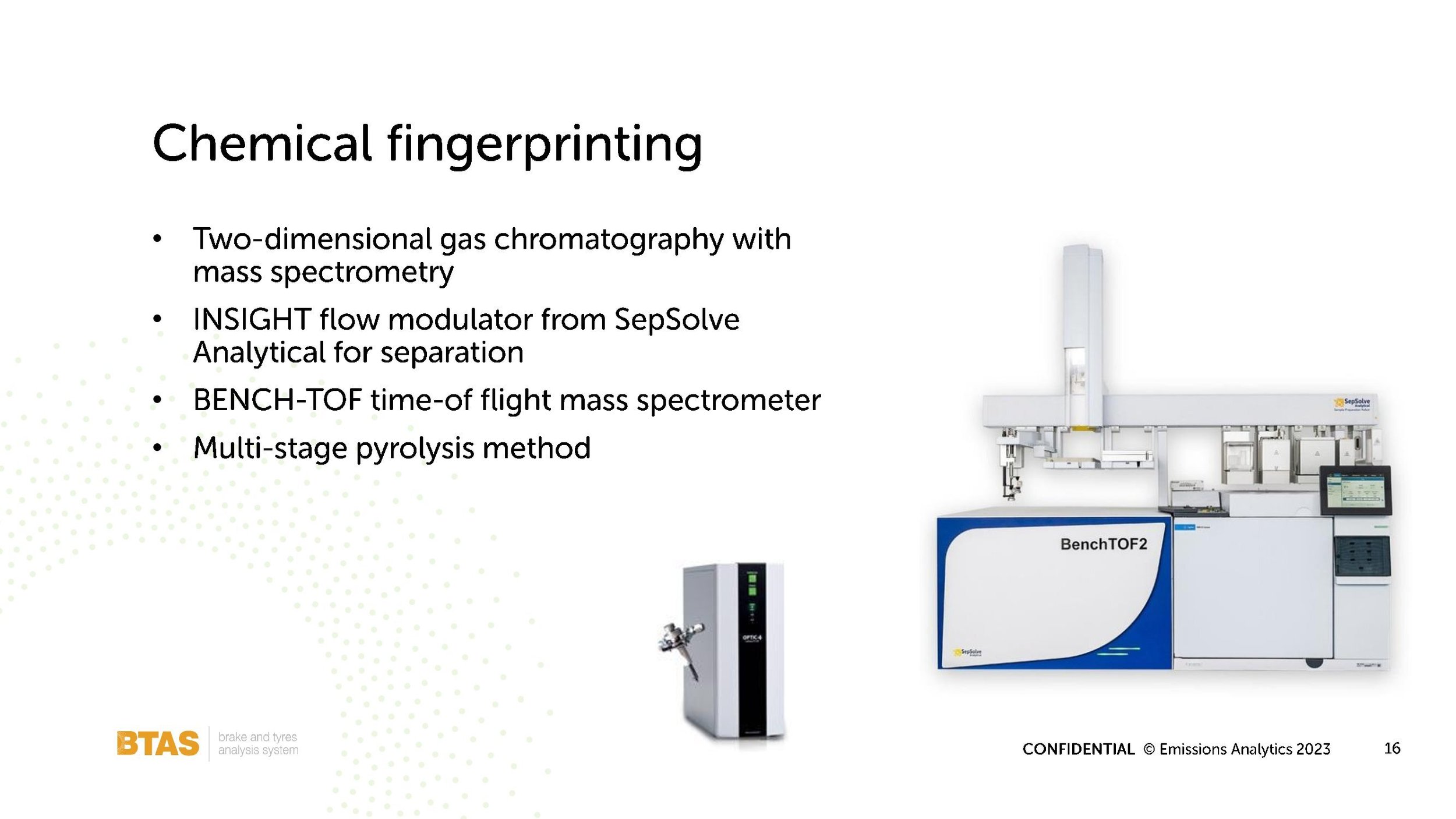

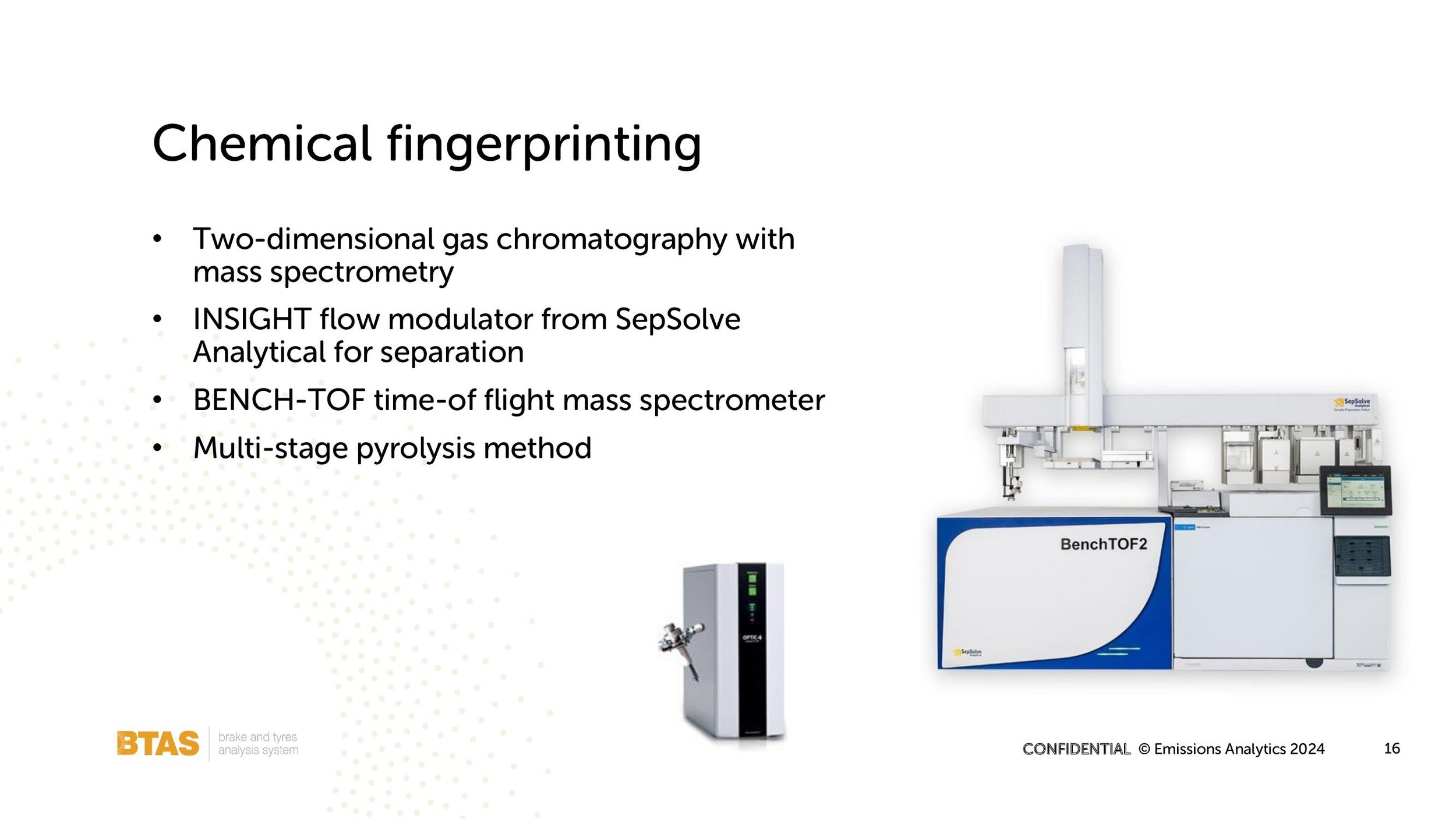

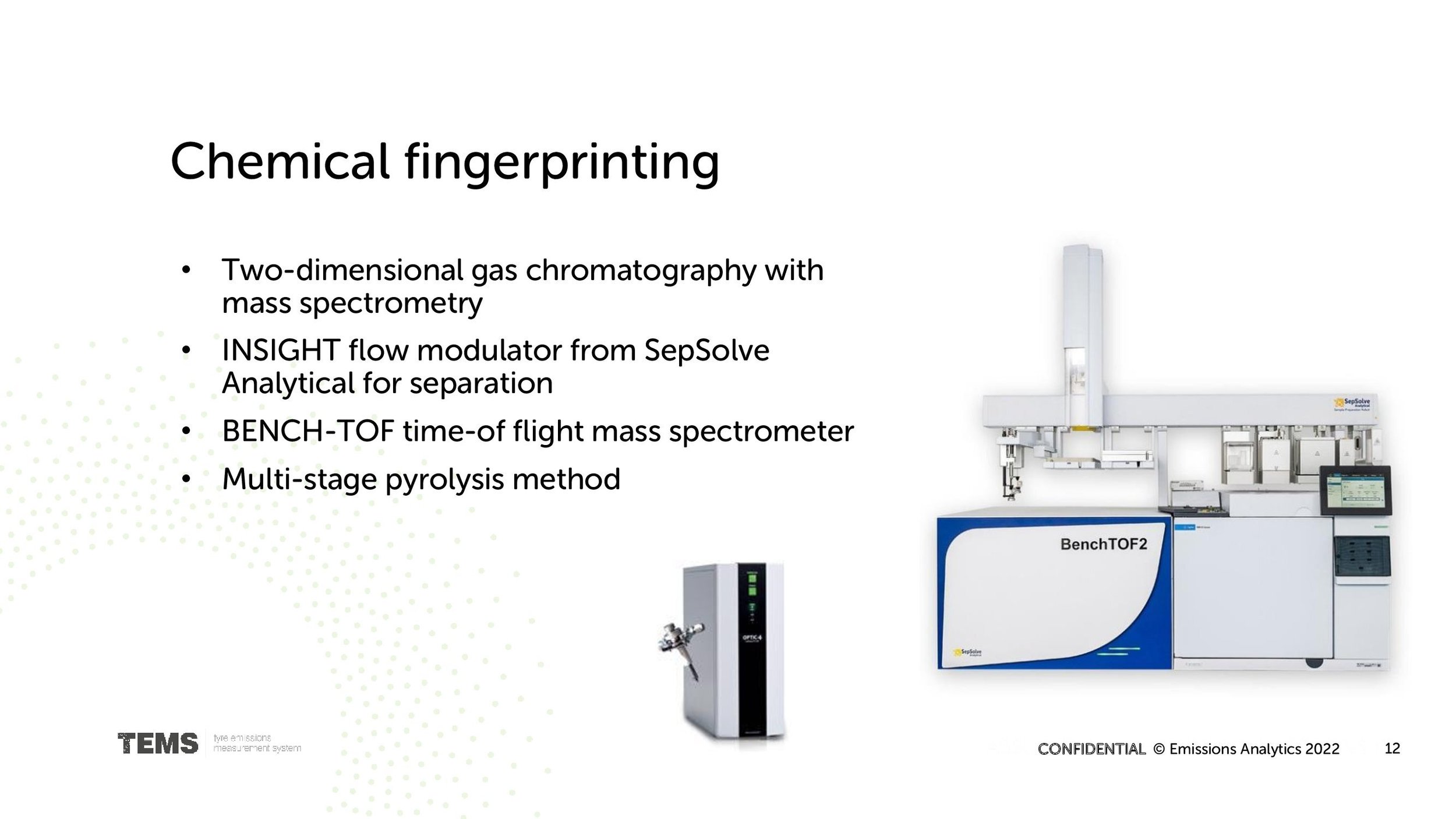

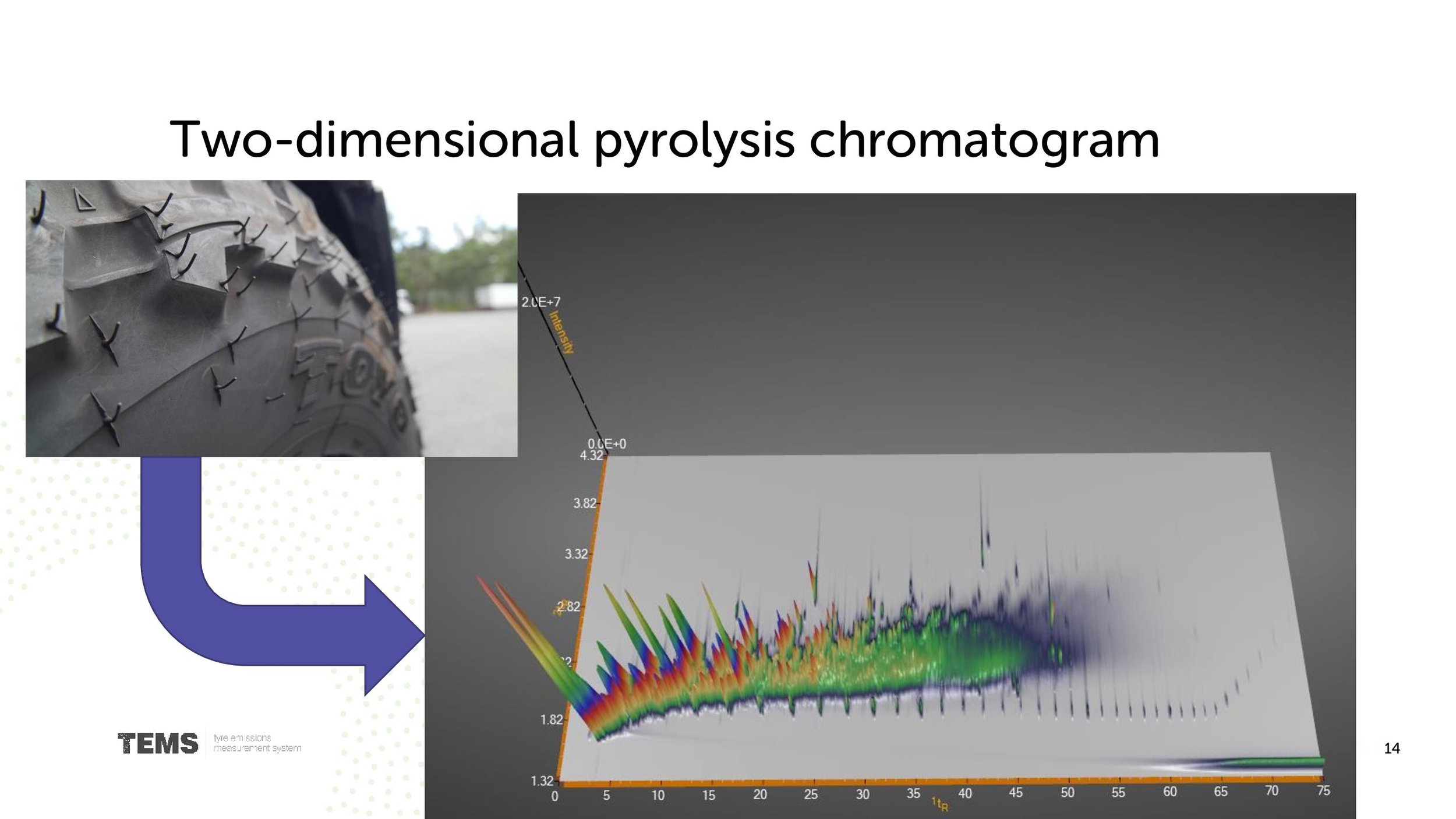

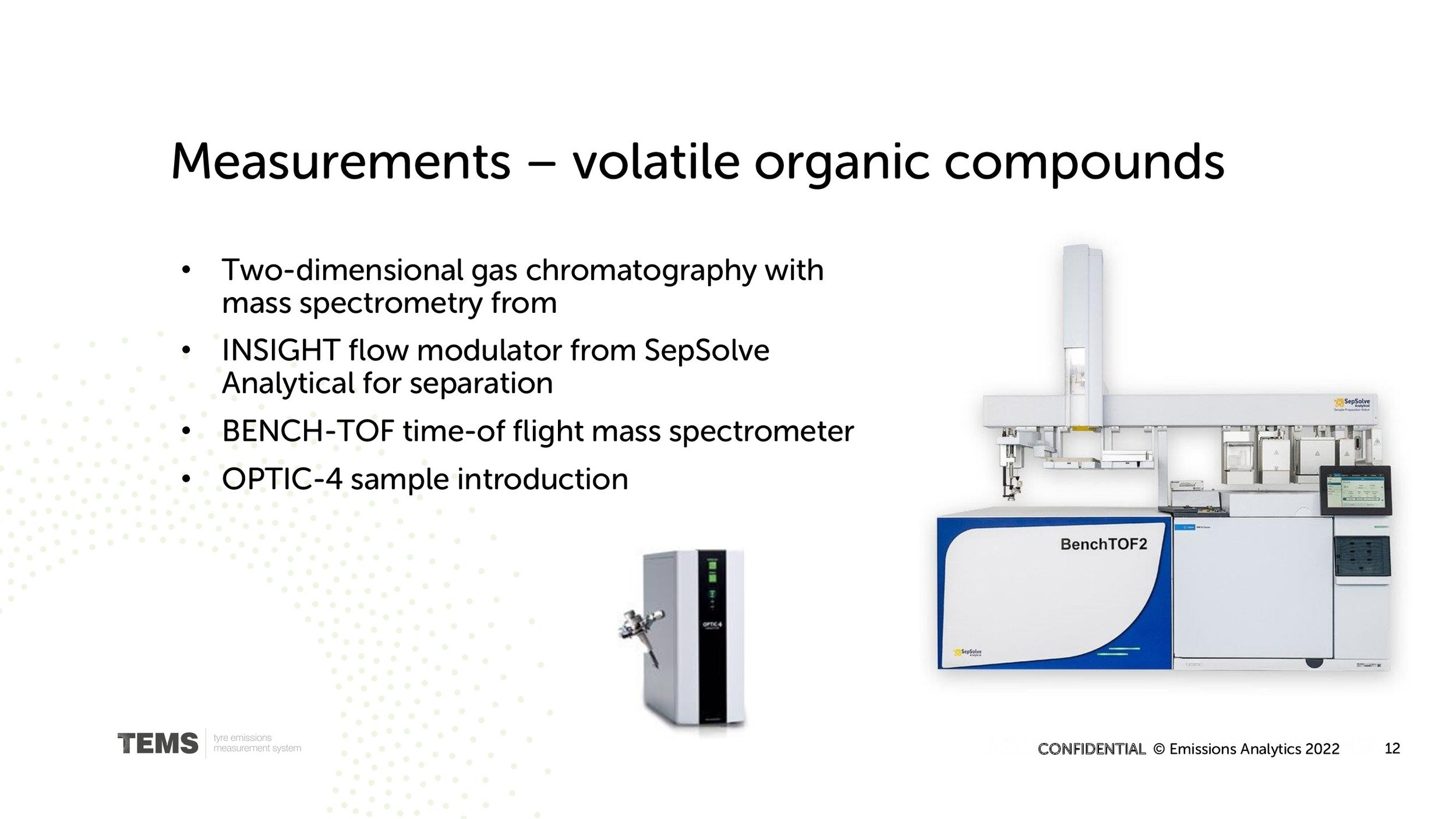

Emissions Analytics has compiled a database of organic compound profiles of hundreds of different tyre models, drawn from over 40 different brands. To achieve this, we have developed a highly optimised analytical pyrolysis method to understand as closely as possible the compounds in the original tyre. This method uses a two-dimensional chromatography system to separate the compounds, which are then identified and quantified using a time-of-flight mass spectrometer. From this, the chemical fingerprint of an ‘average’ tyre can be determined by taking the mean concentration of each compound across all the tyres analysed.

Taking a real sample, we can see how this fingerprinting might work. A water sample was taken from an undisclosed body of water that was believed potentially to contain contaminants or leachates from tyres. It was analysed by ‘solid-phase microextraction’, which essentially involves dipping a thin fibre into the water, which extracts the compounds within. A blank sample of water should show no organic compounds on the chromatogram. Analysis of the sample in fact identified 115 organic compounds, many at the parts-per-billion level. The chromatogram is below, which shows compounds across a wide area and, consequently, many different functional groups.

From this we can conclude that there is very likely to be contamination in this water sample. However, how confident can we be that it comes from tyres?

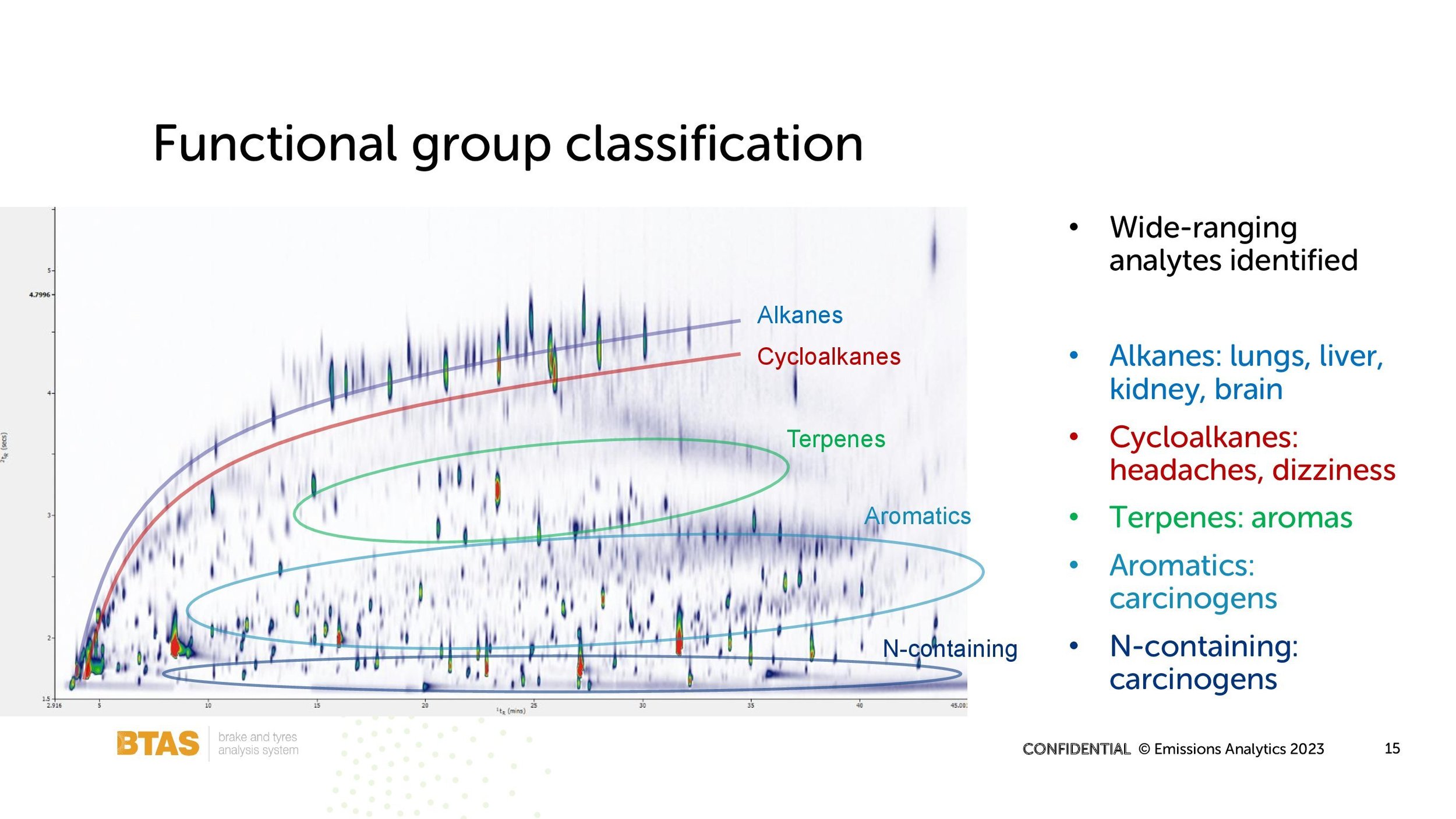

To assess this, we can aggregate the individual compounds represented by the peaks on the chromatogram into functional groups based on their chemical properties: acids, alcohols, aldehydes, and so on. From an environmental and health perspective, the aromatics group is the most concerning as they are often carcinogenic. The esters and terpenes functional groups represent the least concerning compounds, and are most commonly fragrances and flavours. To estimate the prevalence of each group, the area under the peak on each compound is taken, and expressed as a percentage of the total peak area across the whole chromatogram. This gives a chemical profile of the water sample. This can then be compared with the concentrations of chemicals in the Emissions Analytics’ database, averaged across all the tyres tested, in nanograms of target chemical per milligram of sample. The chart below then compares these measures of prevalence between the water sample and the reference database.

The most striking element is the peak of aromatics, which gives good evidence that it is chemicals from tyres that are present in the water. The biggest difference is in the terpenes, principally limonene, which are generally not water soluble and therefore float, so are likely to have been under-sampled. As well as the similar aromatic peaks, there are similar absences of acids and esters between the two samples. The presence of some compounds from the aldehyde and alkane groups suggests the presence of a low level of non-tyre pollution as well in this water sample. Overall, this is a simplified version of what is possible, as more granular functional groups, and even individual compounds, can be used in the fingerprinting.

The same essential approach can be applied to identify tyre wear compounds in soil. Previous research typically identified a small number of organic ‘tracer’ compounds and then used one-dimensional gas chromatography and mass spectrometry (GC-MS) to measure those tracers in the environmental sample. In a recent paper in Chemosphere, ‘Determination of tire wear markers in soil samples and their distribution in roadside soil’, styrene-butadiene rubber (SBR) was used as the tracer, together with thermal desorption and GC-MS, to quantify the distribution of tyre wear at different distances from the roadside. In a further paper in Critical Reviews in Environmental Science and Technology from 2022, ‘Tire wear particles: An emerging threat to soil health’, the use of traditional tracers such as 2-(4-morpholinyl) benzothiazole and hydrogenated resin acids was mentioned, but indicated the need for new and better markers that do not easily leach into water, and are resistant to heat and light exposure. The approach to fingerprinting water samples using two-dimensional gas chromatography and a fingerprinting database may provide that way forward.

Less has been done so far on looking for ultrafine tyre particles in air. Almost by definition, there will be low mass concentrations of tyre particles in air, due to their small size. This is likely to underestimate the potential health effects of such particles, due to their large relative surface area, and the potential for transporting other pollutants, such as VOCs, deep into the human body. This remains, however, work in progress without definitive conclusions. For now, Emissions Analytics is collecting particles as they are shed from tyres in real driving environments. Inevitably, such collection gathers some proportion of non-tyre particles, such as from brakes, road wear and resuspension. The same essential fingerprinting process is being used to estimate what that proportion of non-tyre ‘interference’ in a sample is.

In short, while tyres are highly complex products, containing hundreds of different chemical compounds, the latest analytical techniques present the opportunity for more sophisticated fingerprinting techniques compared to traditional tracer analysis. The tyre tracks can now be followed to understand the ultimate fate of tyre wear in the air, soil and water, and indirectly the effect on human and animal health.

Emissions Analytics featured in Tire Technology International

Emissions Analytics featured in Tire Technology International

Nick Molden interviews with Tire Technology on Emissions Analytics new tyre wear research.

Click the link below to view the edition or scroll below for the interview.

Fishy

Not since the Chevrolet Corvette Stingray or perhaps, more recently, the Citroen Nemo, have cars and fish been so closely associated. But this time it is not branding, but rather the pollution of one by the other.

Not since the Chevrolet Corvette Stingray or perhaps, more recently, the Citroen Nemo, have cars and fish been so closely associated. But this time it is not branding, but rather the pollution of one by the other. That laws are not being broken should be stated up front, and hopefully this will spare us the term ‘Trout-gate’, but nevertheless we need to consider the rapidly emerging evidence linking tyre wear emissions to serious effects on marine wildlife.

Emissions Analytics, in previous newsletters, has evidenced the magnitude of tyre wear emissions, in both mass and number. Many have rightly asked why, if these emissions are so high, has it not been an issue before – which is a good question. An answer is that, until very recently, tailpipe emissions have been high – especially for nitrogen oxides, of Dieselgate fame – and manufacturers have been pursued by authorities and car owners in many states around the world. There are few rules regarding tyre wear emissions, but it is the move towards battery electric vehicles (BEVs), which are typically around 40% heavier than standard internal combustion engine (ICE) vehicles, and which can lead to significantly higher tyre wear, that has brought the issue into focus.

While that has been going on, academic research has been able to link the effects of a chemical in tyres to certain fish populations. A ground-breaking article in Science in 2020, linked a common preservative in tyres – N-phenyl-N'-(1,3-dimethylbutyl)-p-phenylenediamine, commonly known as 6PPD – to unexplained acute mortality when adult salmon migrate to urban creeks to reproduce. Adding 6PPD to tyres prevents hardening and cracking – which can impair durability and safety in operation. 6PPD reacts with ozone in the air to produce 6PPD-quinone, which is the specific compound measured in waters off the US West Coast. However, it was noted, this is unlikely to be an affect unique to coho salmon, or indeed this geographical location.

A more recent study, published in 2022, looked at species of trout, char and sturgeon, and concluded that 6PPD also has toxic effects on both rainbow and brook trout, while the other species were apparently unaffected. More concerning is the potential reinforcing effects when combined with other ambient chemicals, as analysed in this 2022 paper in Science of the Total Environment. The study looked at the effects on population growth of 6PPD and salt on the Brachionus calyciflorus freshwater herbivore. The presence of salt, which could come from road treatment, was found to amplify the effects of 6PPD on these organisms.

These effects matter not just because of the direct impact on wildlife, but also due to the economic effects. Declining populations of salmon and trout may well have detrimental effects on fishing industries. In 2019, commercial landings of coho salmon in the US totalled approximately 12 million kilograms and were valued at more than $30 million, according to NOAA Fisheries. Around 95% of the US coho salmon harvest comes from Alaska, where the impact of declining fish stocks on the livelihoods of the local population could be significant. Rainbow trout production for food in the US is around 27 million kilograms, with about three quarters coming from Idaho. Revenues generated are typically over $70-90 million per year.

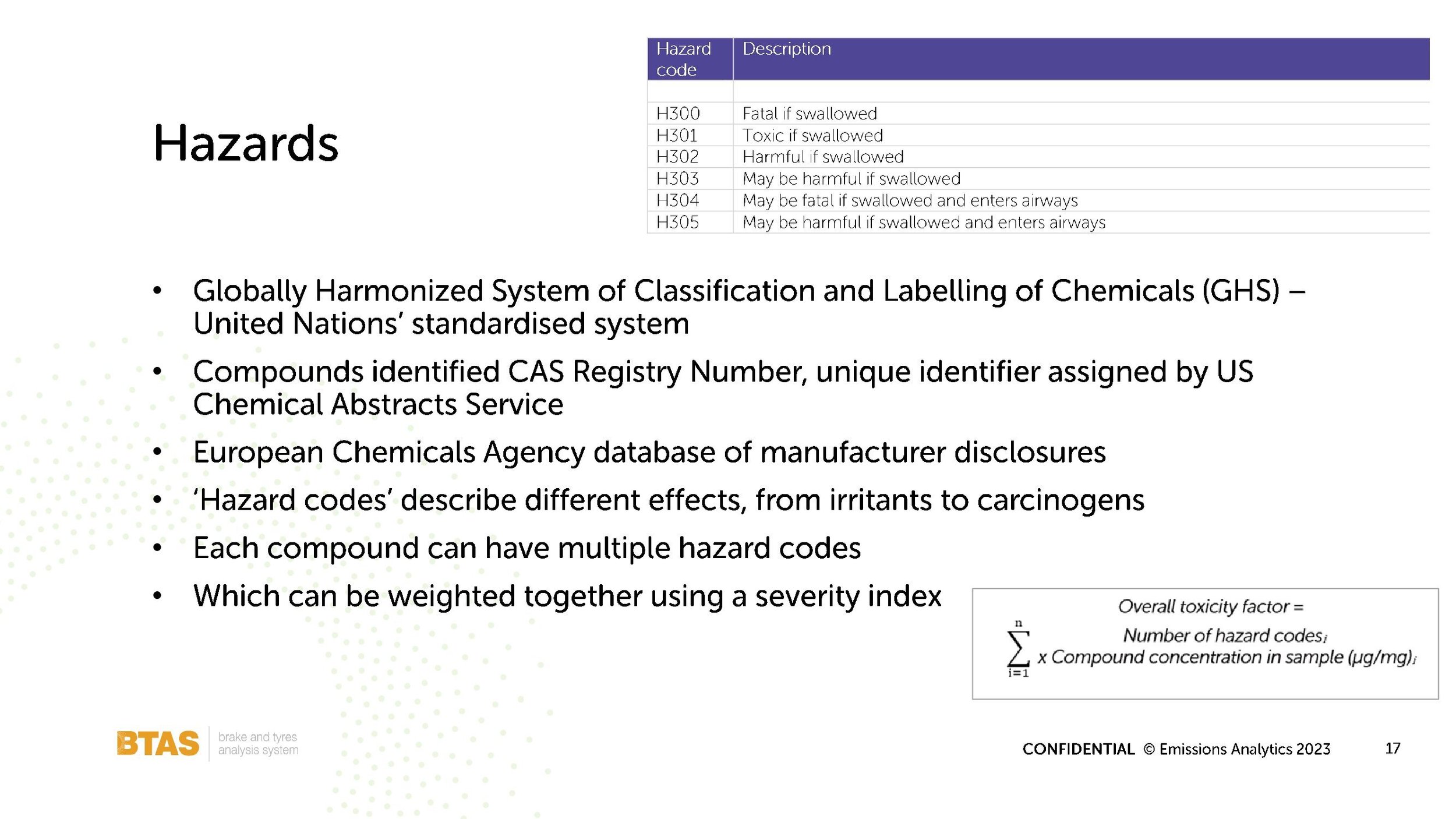

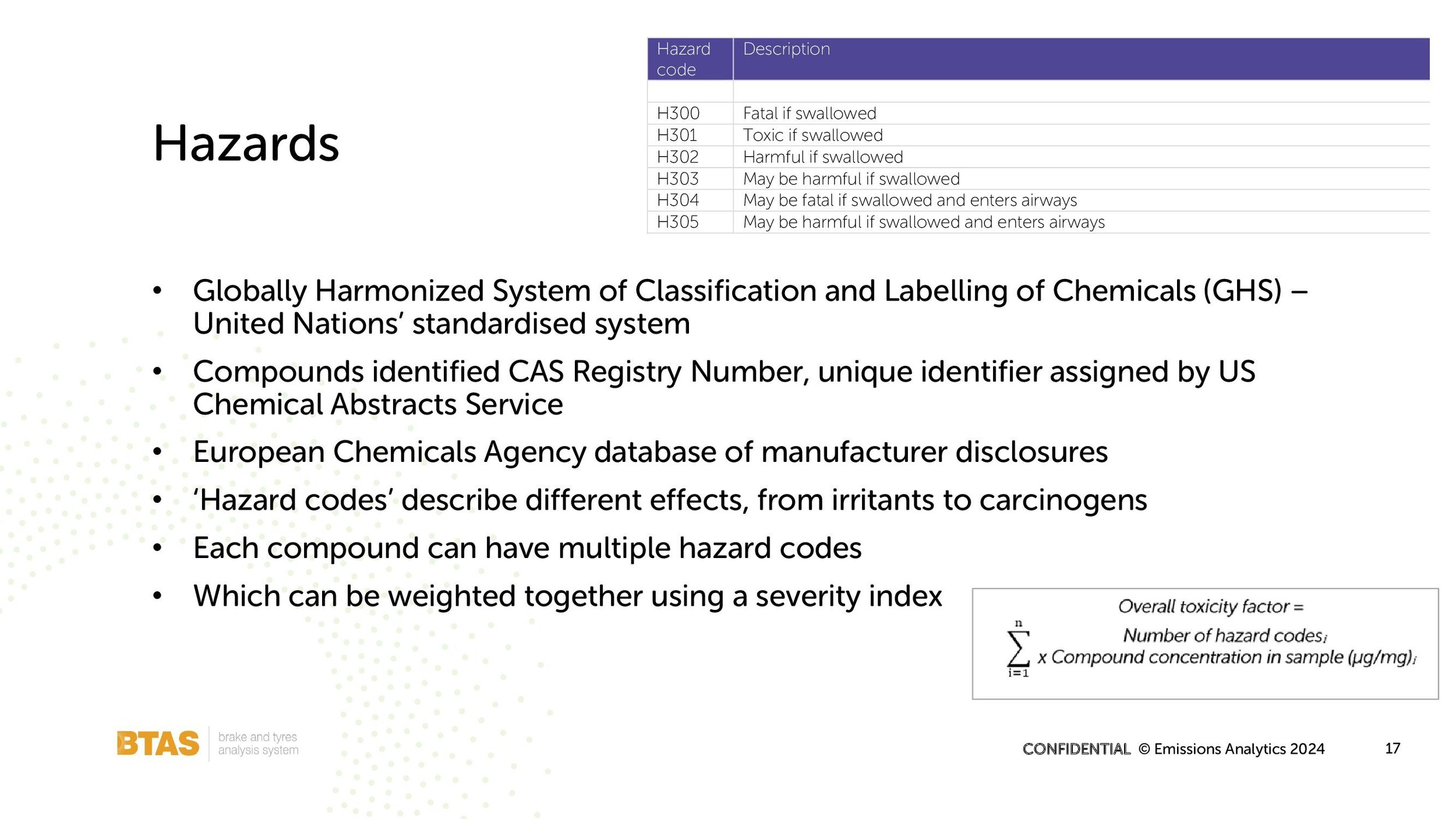

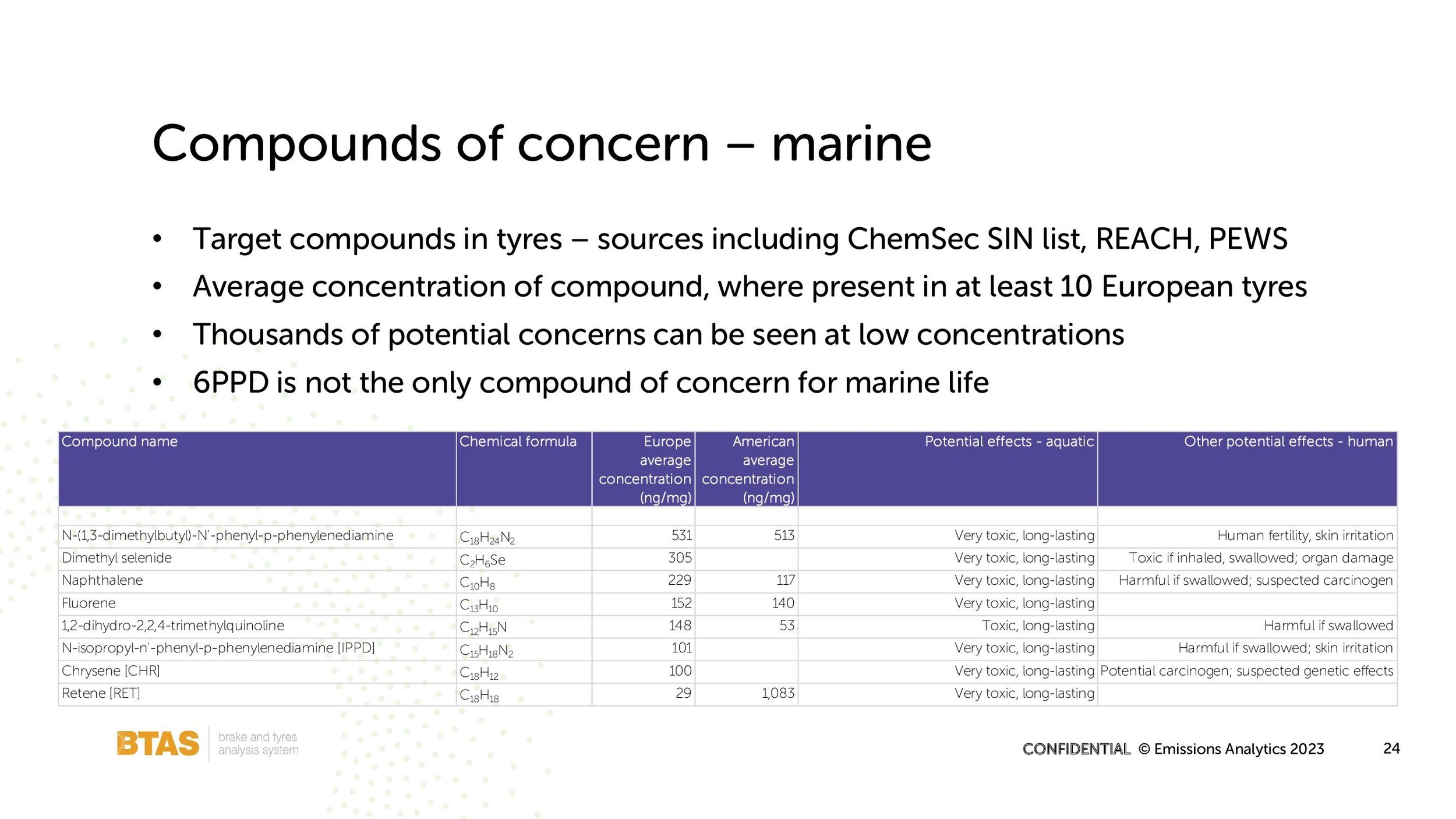

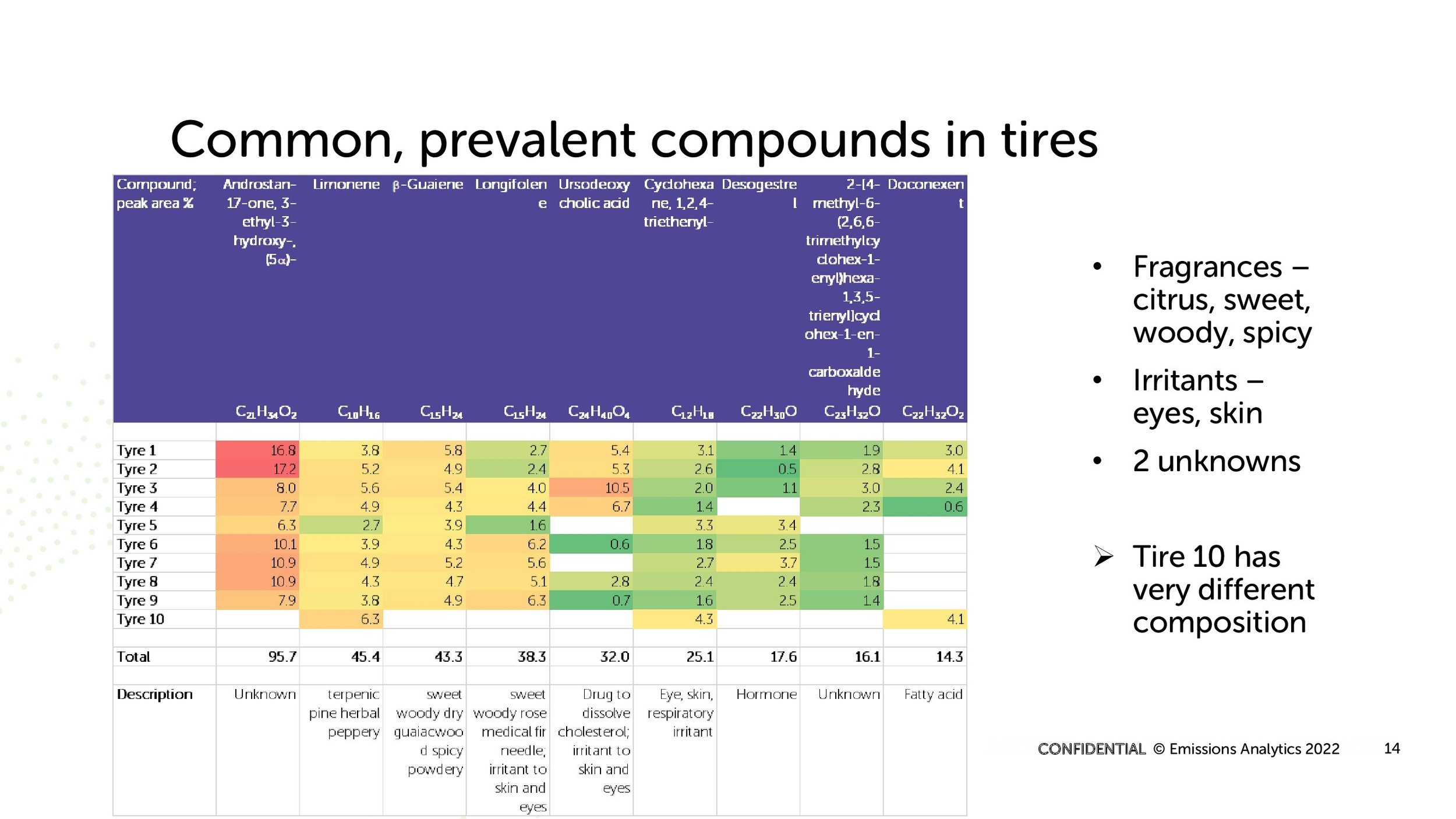

As the academic evidence has accumulated, Emissions Analytics has been building a detailed database of the organic compounds in hundreds of new tyres on the market. The test equipment and method has been described in previous newsletters. As a result, we are now able to start quantifying the potential release of such chemicals, which can then provide a baseline from which policy could target their reduction. Before this can happen, however, it is necessary to evolve the traditional association of vehicle emissions with air quality, to a wider concept of the effect of vehicle emissions on the environment more generally – most importantly on marine and soil environments. This is essential if we are not to underestimate the effects of tyres.

While the most common in tyres, 6PPD is not the only preservative available. Potential other compounds are 7PPD (N-(1,4-dimethylpentyl)-N'-phenyl-p-phenylenediamine) and IPPD (N-Isopropyl-N′-phenyl-1,4-phenylenediamine). Across the more than 200 tyres tested so far, we can see the prevalence of each of these compounds, as set out in the table below.

The concentration is the amount of the compound – on a toluene equivalent basis of quantification – as a proportion of the tyre sample mass, and is measured using two-dimensional gas chromatography and time-of-flight mass spectrometry on samples taken directly from new tyres. Although the method is highly sensitive – picking up compounds at concentrations as low as parts-per-trillion – there is a lower limit of detection and, therefore, where the compounds are reported as not present, the concentration may just be below that lower limit.

These results show that a small minority of tyres currently contain IPPD, whereas almost all contain 6PPD. While it is a reasonable hypothesis that 6PPD and IPPD are substitutes for one another, the correlation between their concentrations in this dataset is weak, apparently because other factors determine each brand’s approach to the use of preservatives.

Drilling down to the individual tyres and their manufacturers, we can see how concentrations and compound mixes vary between the five manufacturers using the smallest amount of IPPD as a proportion of their total use of preservatives, compared to the five using the most, as shown in the table below.

If the average concentration of 6PPD is multiplied by the average lifetime wear rate of a set of tyres of 37 mg/km, that is approximately 33 µg/km of 6PPD released by an average car. When that is applied across the roughly 250 million cars on the roads of Europe and an average distance of about 16,000 km per year, the total 6PPD potentially released annually into the environment is approximately 130 tonnes in Europe.

As a cross-reference for the plausibility of significant 6PPD being released in this way, another study from 2022 assessed the concentration and leachability of 6PPD and 6PPD-quinone in road dust collected in Tokyo, Japan. The widespread presence of these compounds was confirmed by their presence in all the samples collected. Concentrations were higher typically where there was more traffic volume, suggesting a strong dependency, along with a weaker dependency on seasonal conditions.

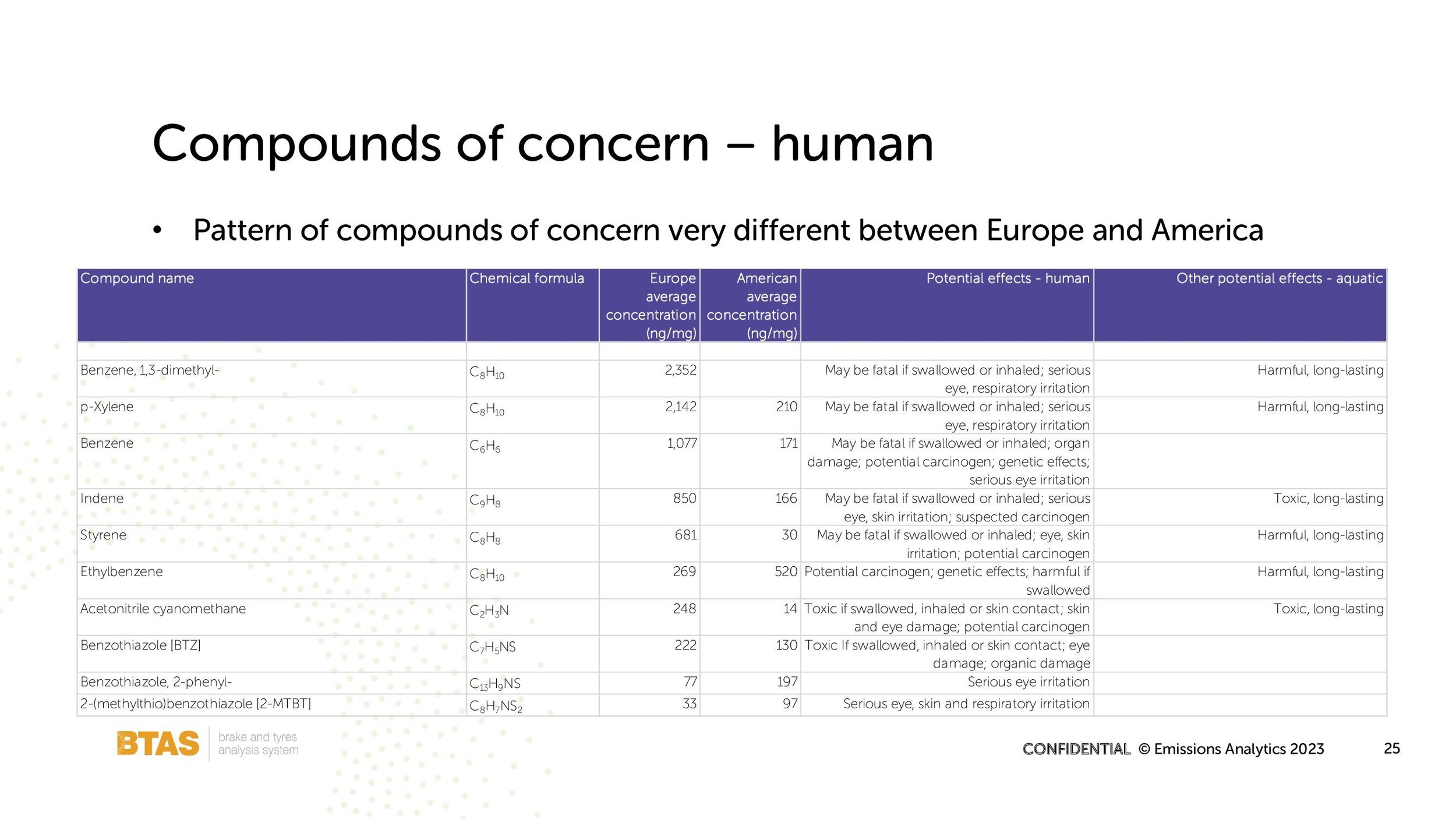

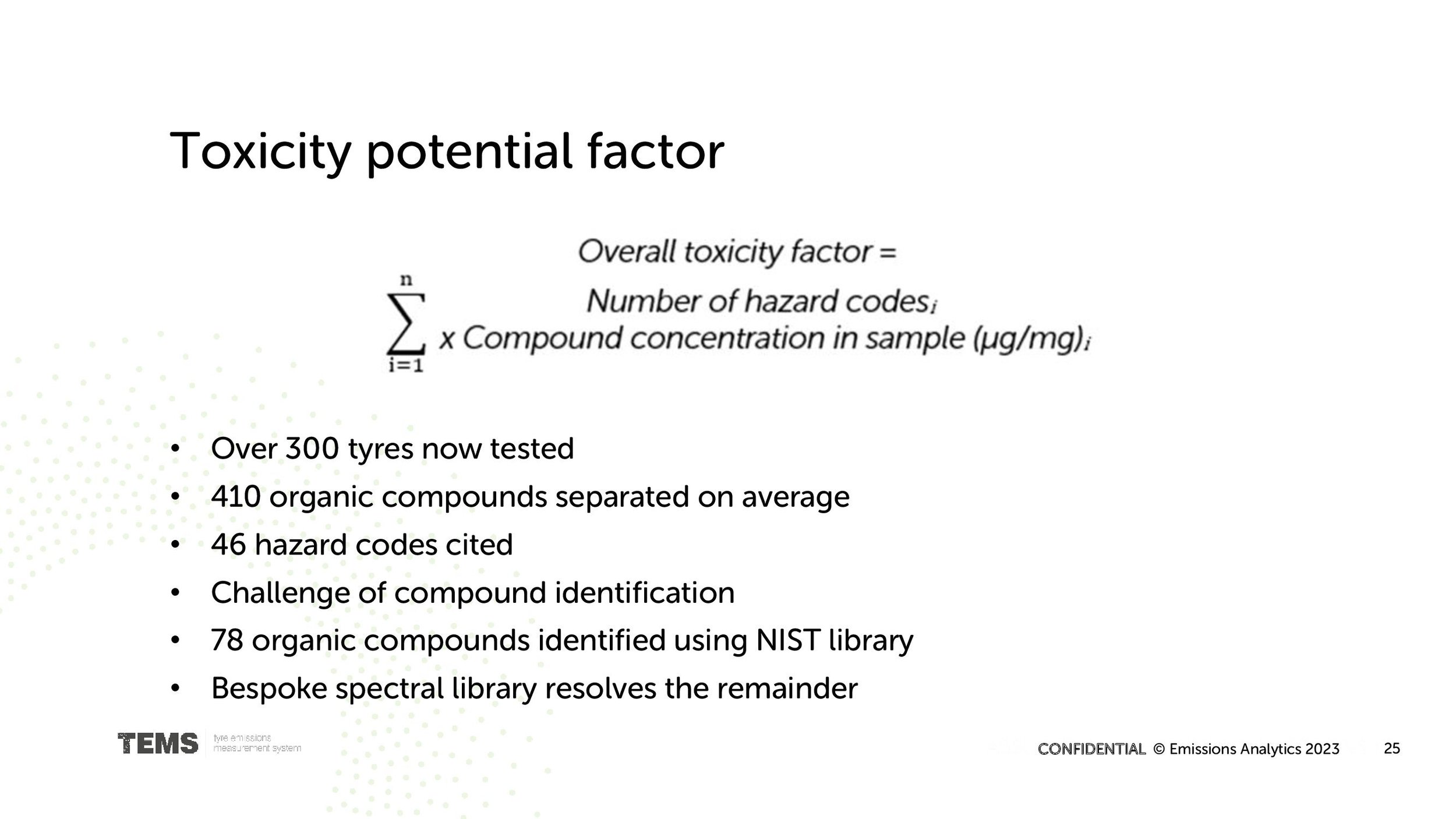

In the analysis above we have considered the environmental impacts of just two compounds in tyres. On average, across all the tyres tested, 410 organic compounds are identified per tyre, across functional groups such as alkanes, aldehydes, aromatics and polycyclic aromatic hydrocarbons. Therefore, there is significant further research to do to understand the potential effects of the multitude of other compounds in tyres. Furthermore, less than one quarter of the compounds are identified by the standard spectral libraries with a sufficient level of confidence, and consequently there is a significant number of compounds unknown to all except perhaps the tyre manufacturer itself.

Authorities and regulators and now looking at this area actively. The Department of Toxic Substances Control (DTSC) in California is proposing a regulation to list Motor Vehicle Tires containing 6PPD as a ‘Priority Product’. DTSC has determined that there is potential for exposure to 6PPD from these products and for that exposure, “to cause or contribute to significant or widespread adverse impacts.” A public consultation is ongoing. The UNECE together with the EU are now actively working on a standardised method for measuring tyre wear rates, which would be a natural precursor to wider consideration of the chemical composition of tyres beyond the few compounds currently limited under REACH.

In summary, with the growing ability to identify compounds both inherent in tyres and mixed into samples collected in the environment, it is possible that we will progressively find further links between tyre ingredients or derivative compounds and deleterious environmental effects. Emissions Analytics is continuing its work to test a wide range of tyres around the world and resolve the currently unidentified compounds. What we can be certain of today is that tyres – while all looking very similar – are made with recipes that vary significantly between products, and that the total material released each year is large, dwarfing the particulate matter released from the tailpipes of modern combustion engines, which Emissions Analytics also continues to track through its EQUA programme.

Emissions Analytics Featured on BBC Radio 4’s More or Less

Emissions Analytics featured on BBC Radio 4 on our tyre research.

On 22nd June 2022, Emissions Analytics featured on BBC Radio 4’s on our tyre research.

To listen to the research we have conducted on tyre wear please click on the link below and scroll to 19 minutes and 15 seconds.

PRESS RELEASE: Emissions Analytics launches new chemical fingerprint tyre database available by subscription

Leading international vehicle emissions testing company, Emissions Analytics, today launches an innovative tyre database, the product of over two years of testing and evaluation.

Leading international vehicle emissions testing company, Emissions Analytics, today launches an innovative tyre database, the product of over two years of testing and evaluation.

Non-exhaust emissions are of growing environmental concern with tyre emissions under significant scrutiny. The EU-Commissioned research paper ‘Plastics in the Marine Environment’ found that tyres were the leading single cause of marine microplastics, amounting to 270 million tonnes per annum. It is crucial that as an industry, we develop our understanding of the nature and magnitude of this challenge.

The product of over two years of testing and evaluation, Emissions Analytics launches EQUA Tyre, an innovative organic compound profiling and benchmarking database, containing test results and raw data from independently-sourced samples from over 40 manufacturers and hundreds of different models of tyre.

Tyres are a complex mix of components and compounds. To be able to separate and identify all the organic compounds, Emissions Analytics utilises two-dimensional gas chromatography coupled with time-of-flight mass spectrometry to yield a unique and detailed chemical fingerprint for each tyre. The test method is designed to simulate the leaching of organic compounds over time from tyres and their wear products.

EQUA Tyre joins the broader stable of EQUA databases, comprising EQUA Tailpipe and EQUA Cabin for over 2,500 vehicles.

Research results show that certain product formulations lead to environmental impacts three times higher than alternative formulations. As a consequence, tyres not only vary significantly in wear rates, but also in chemical composition and environmental effects.

The aim of EQUA Tyre is to bring transparency to an area that has historically been under-researched, and which is now in the spotlight as a result of ever-heavier vehicles and rapidly cleaning tailpipes.

This launch comes at an important time, as the European Union considers the potential new Euro 7 vehicle emissions regulation and whether to incorporate limits for non-exhaust emissions.

The purpose of the EQUA Tyre database is to furnish tyre OEMs and other suppliers, regulatory bodies and non-governmental interested parties with access to a comprehensive, independent assessment of tyre composition.

This potentially points to the best ways to drive reductions in environmental and health impact through incentives to develop improved products. It further offers the opportunity to understand the sources of microplastics being observed in air, water and soil samples.

The resulting data is unique in the global tyre industry and the first major effort towards a comprehensive understanding of tyre composition affecting all matters, from tyre performance to environmental impact.

Access to this unique database will be available on corporate subscription and we are pleased also to offer confidential laboratory testing services to our partners globally.

On the launch of the database, Emissions Analytics’ founder and chief executive officer, Nick Molden, commented: “Tyres are rapidly eclipsing the tailpipe as a major source of emissions from vehicles, but the nature of tyre wear is poorly understood. The new EQUA Tyre database marks a milestone in measurement, and which can offer a foundation for developing solutions.”

If you would like to access to our tyre database, please contact us.

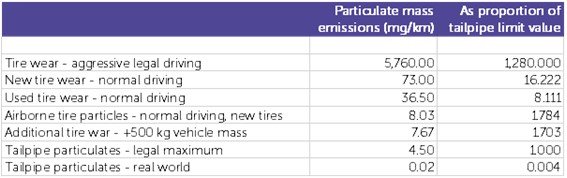

Gaining traction, losing tread Pollution from tire wear now 1,850 times worse than exhaust emissions

By some distance, the research Emissions Analytics published in early 2020 claiming that tire particulate wear emissions were 1,000 times worse than exhaust emissions generated the most feedback of any subject we have tackled so far – feedback that was a mixture of surprise and scepticism

By some distance, the research Emissions Analytics published in early 2020 claiming that tire particulate wear emissions were 1,000 times worse than exhaust emissions generated the most feedback of any subject we have tackled so far – feedback that was a mixture of surprise and scepticism.

Of particular attention was whether such a rate of wear would mean that any tire could be spent within just a few thousand miles with legal driving, however aggressive. Particularly vocal were the battery electric vehicle (BEV) community, sensitive to any suggestion that the added weight of these vehicles might lead to tire wear emissions that might confound the ‘zero emissions’ tag. Such was the reaction, the story was translated into over 40 languages worldwide.

Since that study, which was transparently designed to quantify the worst-case tire emissions under legal driving, Emissions Analytics has been testing and analysing tire wear emissions in more detail across a wider range of driving conditions, and has performed a detailed chemical analysis of hundreds of new tires. Furthermore, we have worked with the National Physical Laboratory in the UK objectively to quantify the uncertainties in our measurements of chemical composition.

The headline conclusion we draw now is that, comparing real-world tailpipe particulate mass emissions to tire wear emissions, both in ‘normal’ driving, the latter is actually around 1,850 times greater than the former. Yes, in normal driving the ratio is almost double the previous figure for aggressive driving.

Quoting such ratios, however, needs careful interpretation. The fundamental trends that drive this ratio are: tailpipe particulate emissions are much lower on new cars, and tire wear emissions increase with vehicle mass and aggressiveness of driving style. Tailpipe emissions are falling over time, as exhaust filters become more efficient and with the prospect of extending the measurement of particulates under the potential future Euro 7 regulation, while tire wear emissions are rising as vehicles become heavier and added power and torque is placed at the driver’s disposal. On current trends, the ratio may well continue to increase.

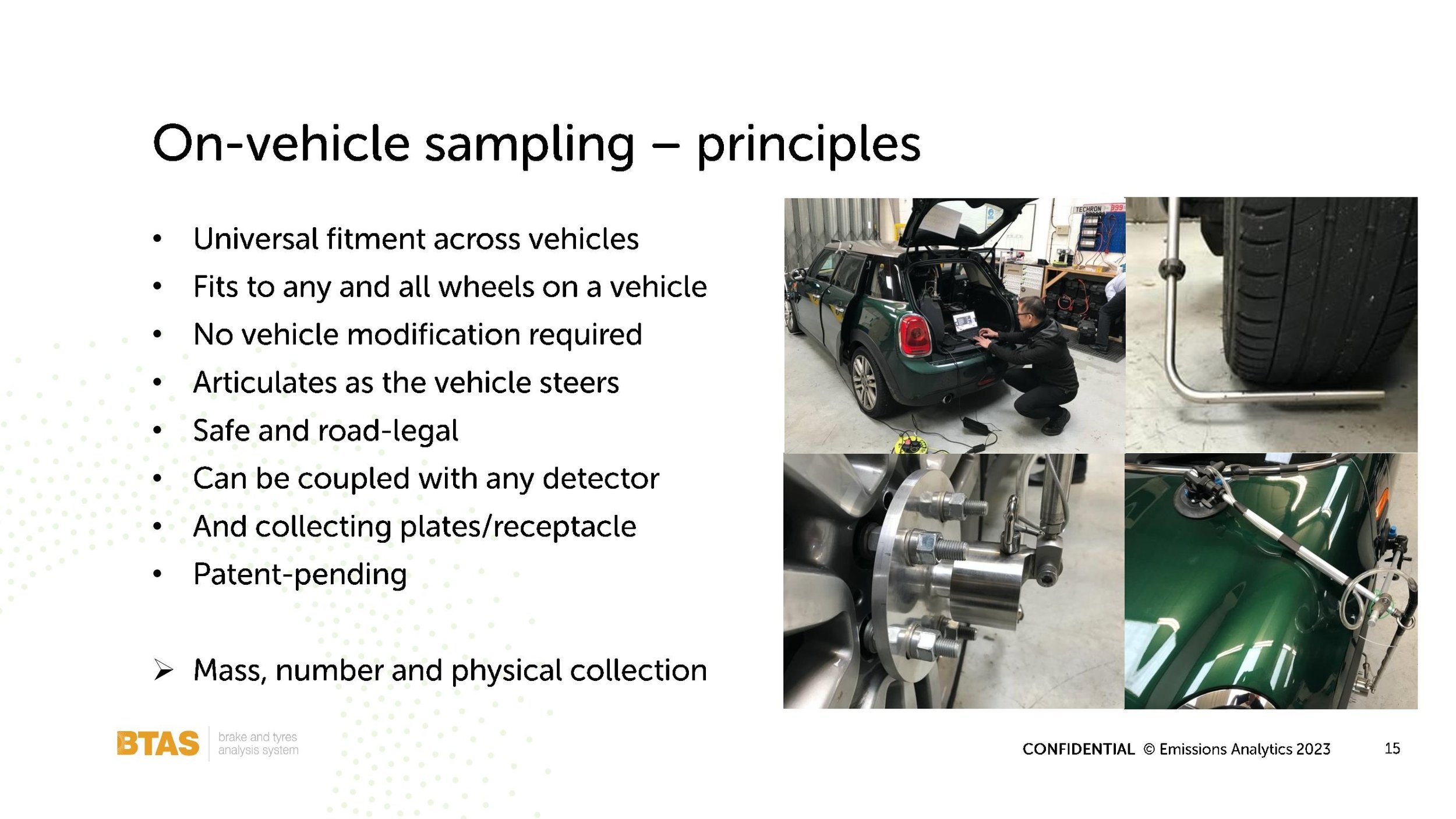

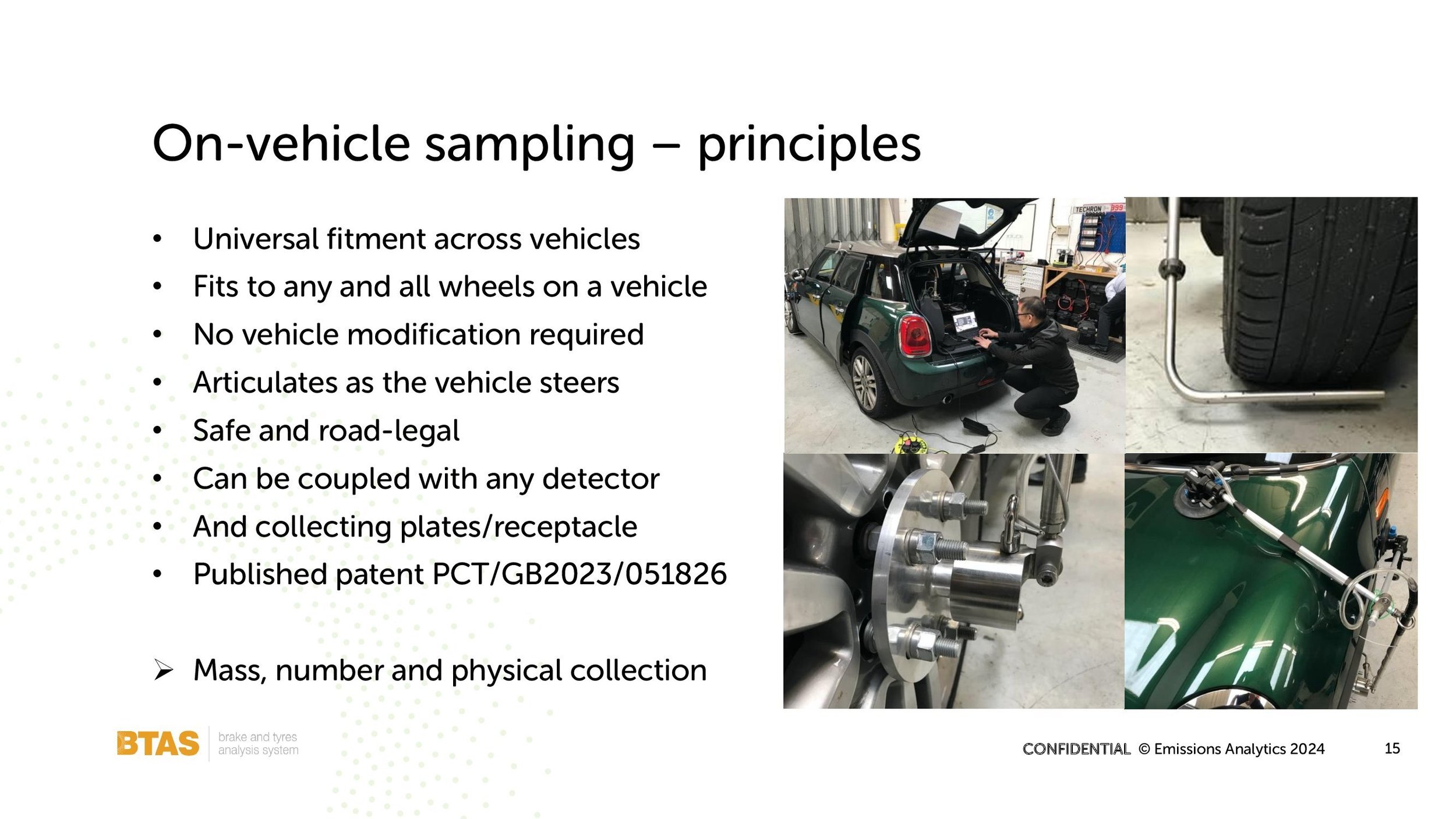

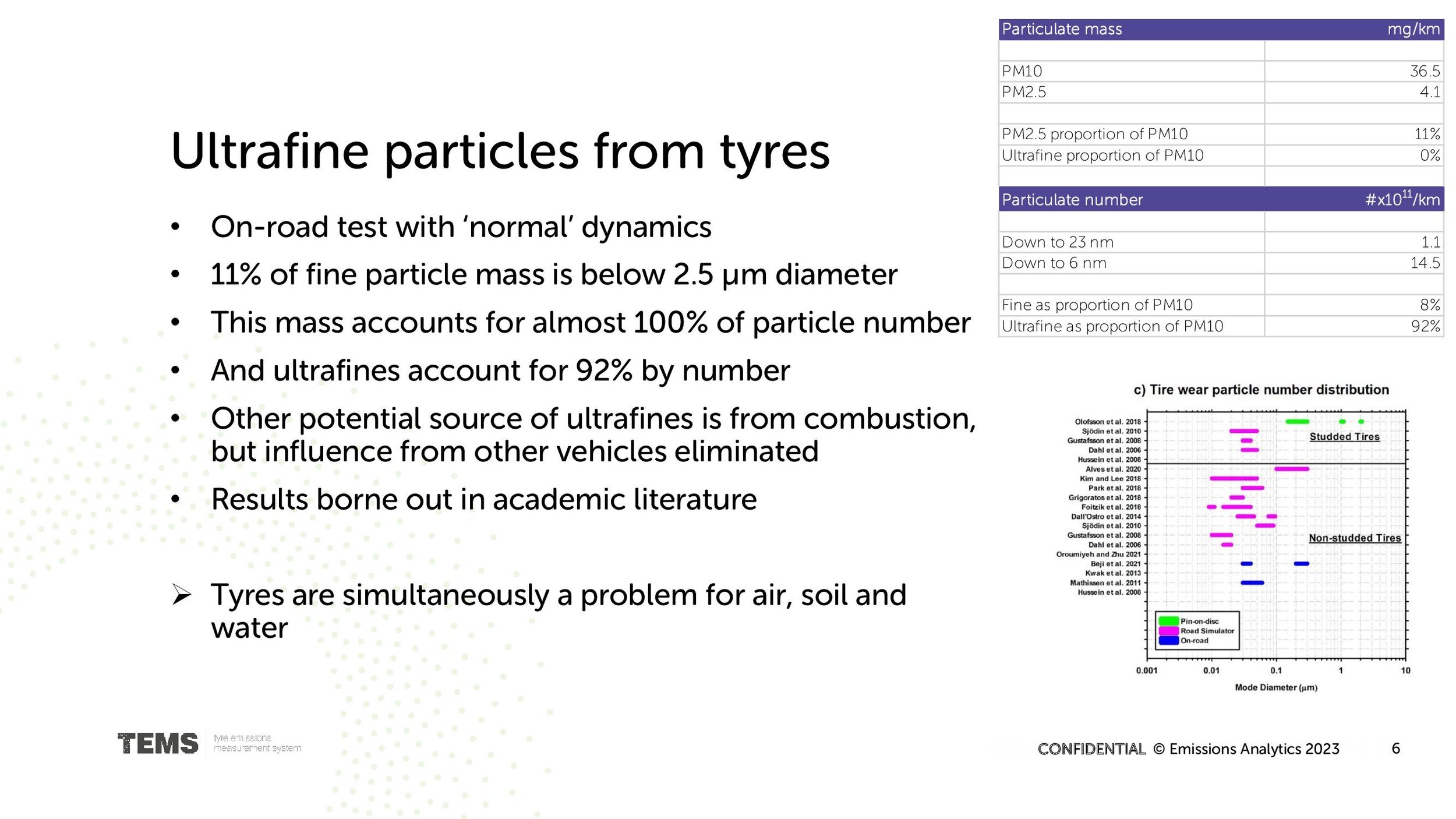

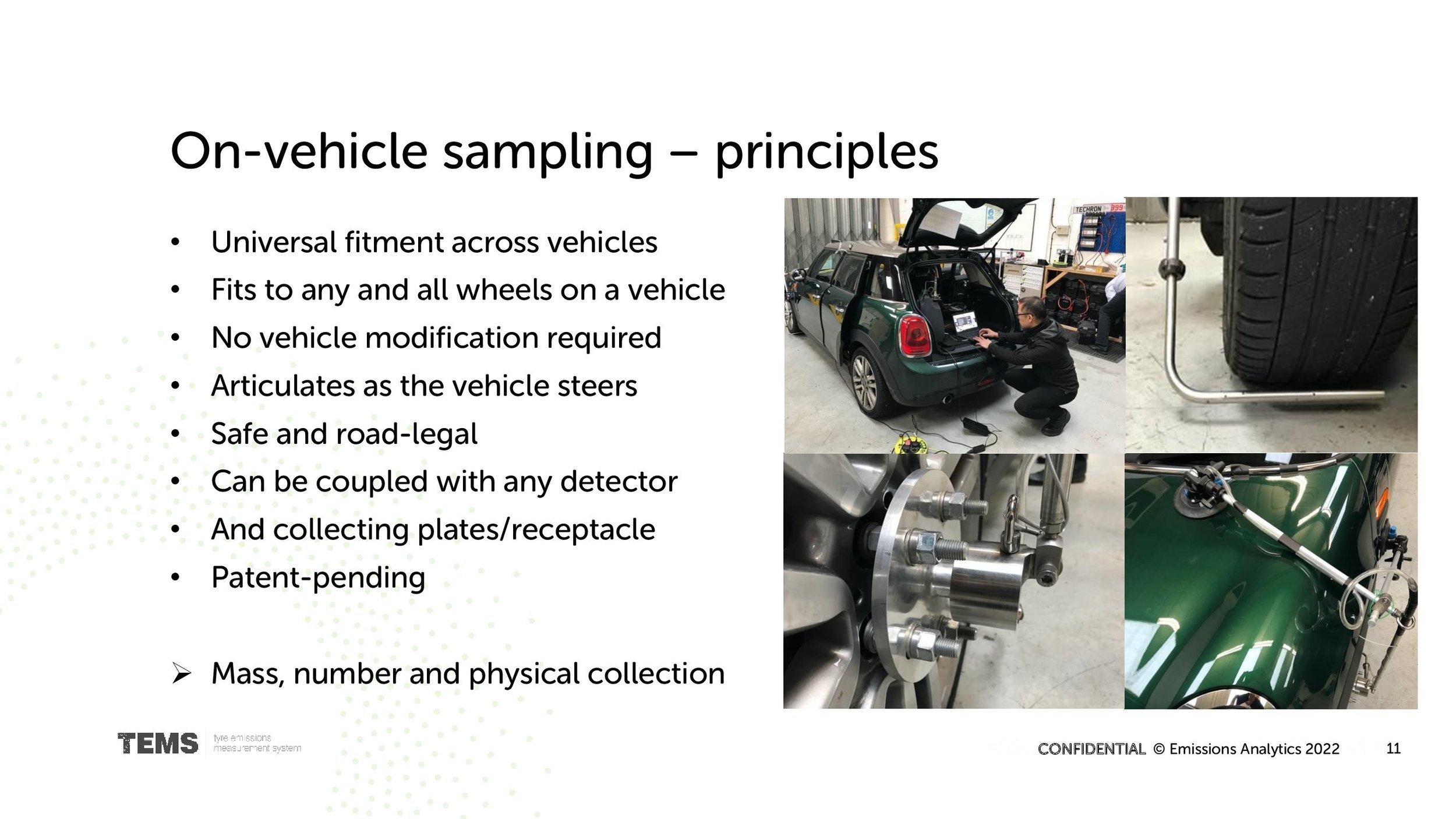

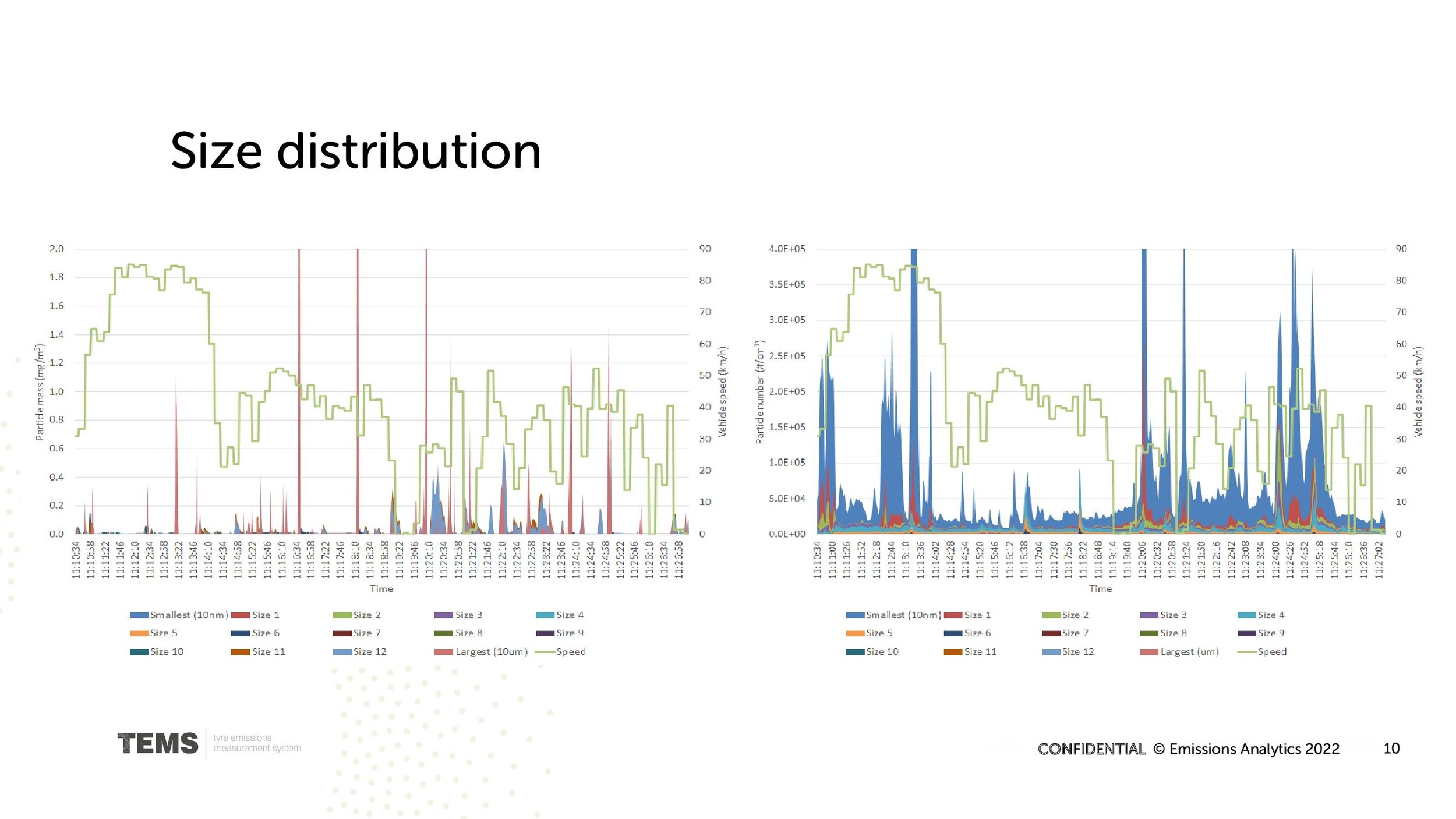

To measure tire wear mass emissions, Emissions Analytics uses high-precision scales to weigh all four wheels – tires and rims together, without detaching – over at least 1,000 miles on real roads. This is coupled with a proprietary sampling system that collects particles at a fixed point immediately behind each tire, which are, via a sample line, drawn into a real-time detector measuring the size of distribution of particles by mass and number. Typically, this measures particles from 10 microns down to 6 nanometres. This combination allows the real-time signal to be calibrated to the mass loss, and, by using the size distribution, the proportion of the particles likely to be suspended in the air can be estimated. All tire emissions figures quoted here are for the whole vehicle, combining wear from the four tires.

Tailpipe particles are measured, in similar real-world conditions, using a diffusion charger analyser for dynamic mass concentration and a condensing particle counter for number concentration, both coupled with a standard Portable Emissions Measurement System (PEMS) to measure total exhaust flow. As a result, distance-specific mass and number emissions can be derived, which can then be compared to equivalent tire metrics. A summary of the results is shown in the table and chart below.

The comparison is best illustrated by way of a bar chart with a logarithmic vertical scale, as shown below.

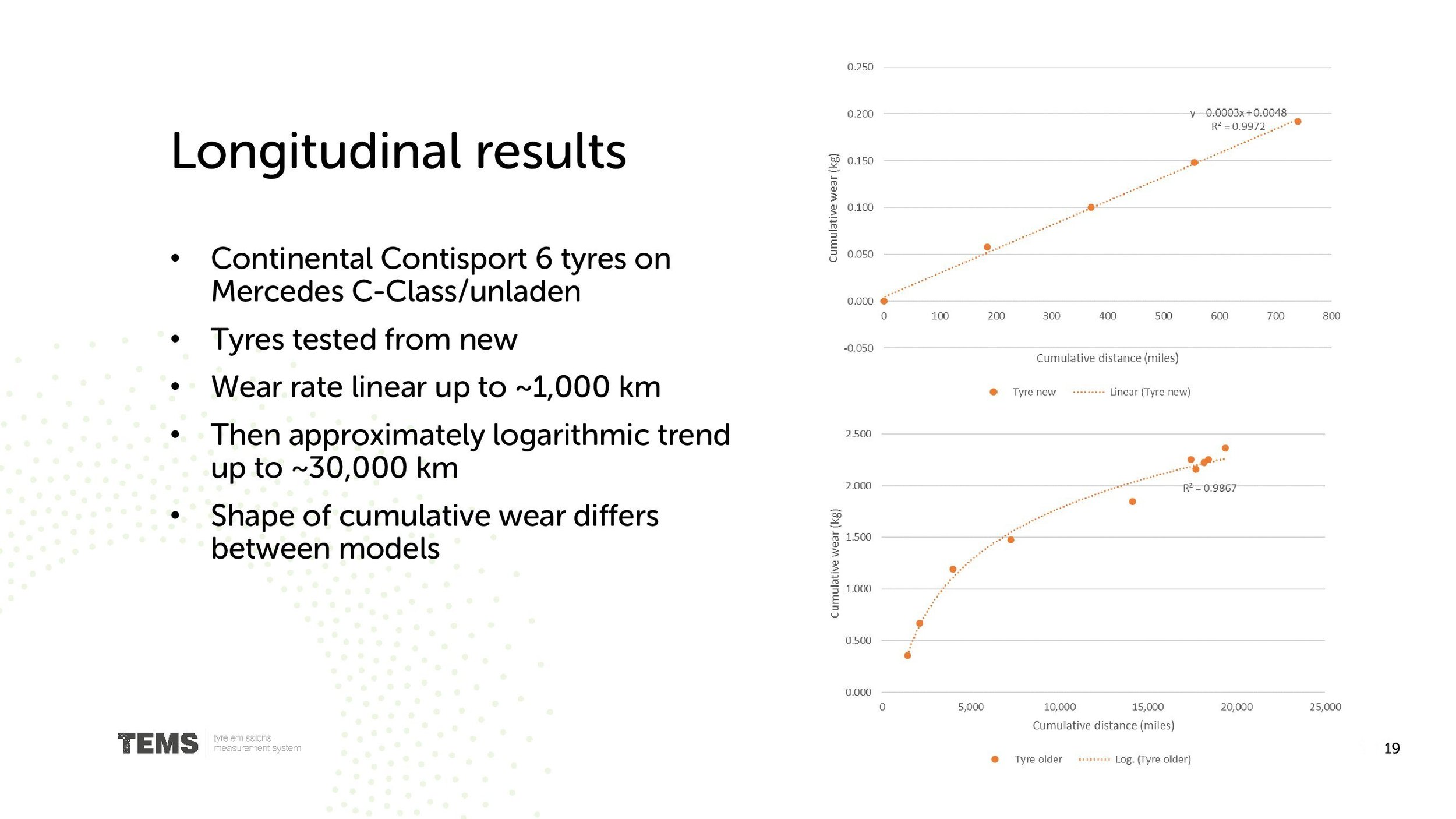

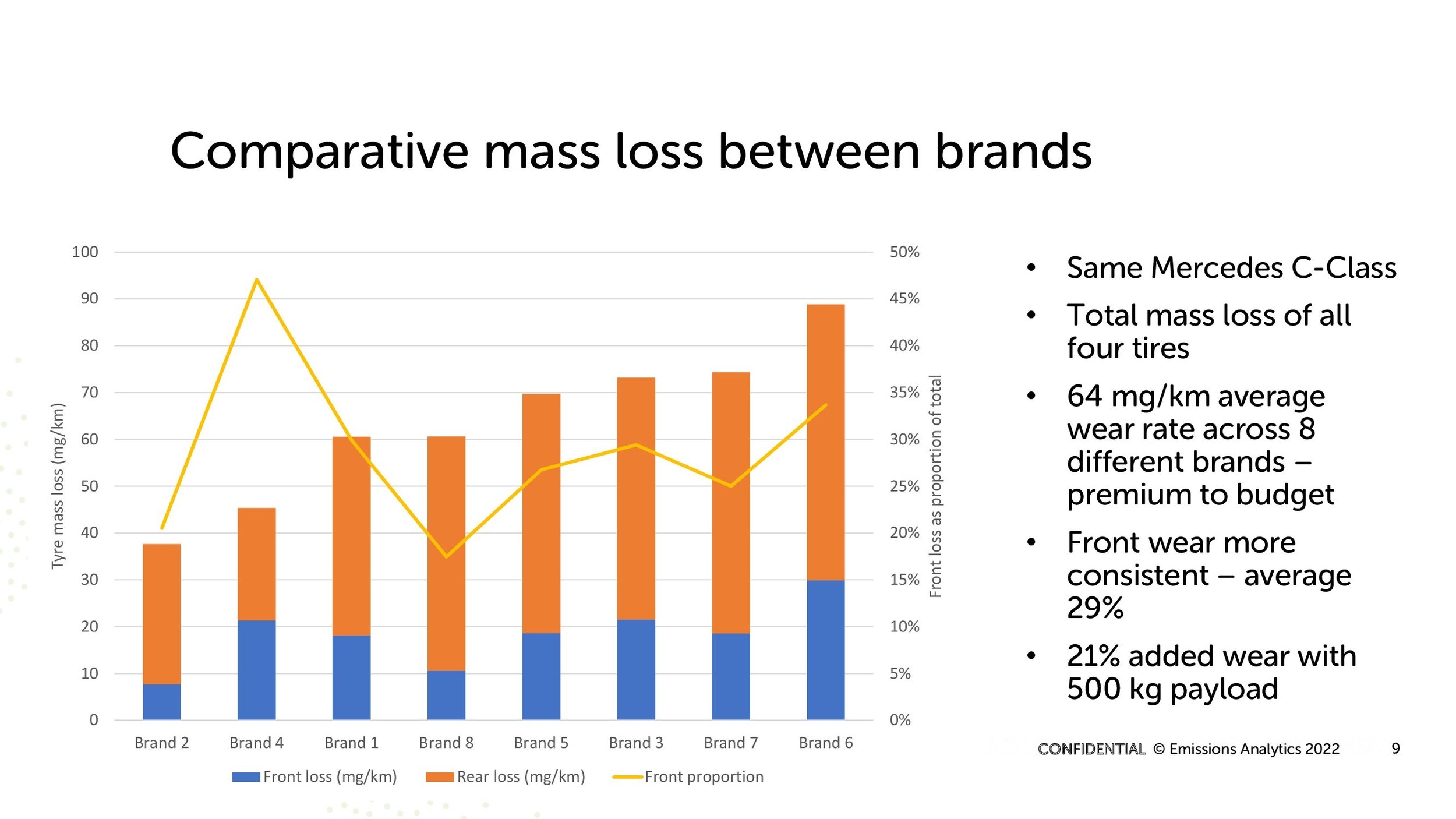

The aggressive legal driving is the result from 2020, which was derived from a Volkswagen Golf driven at legal road speeds on a track, with fast cornering and maximum permitted payload in the vehicle. The normal driving results were averaged across 14 different brands of tire tested on a Mercedes C-Class driven with average dynamics on the road, with just the driver and no payload in the vehicle. All of these tires were tested from new. A smaller number of tires were then tested over their full lifetime in order to estimate the degree to which wear rates declined over time.

The tailpipe real-world emissions were measured across four gasoline mid-sized sports utility vehicles from 2019 and 2020 model years, driven on a mix of urban and motorway routes. The payload was the driver and test equipment only. For these vehicles, the relevant regulated limit value in Europe – which is the same limit in force for current vehicles – was 4.5 mg/km for mass and 6.0 x 10¹¹ #/km for number.

Quite remarkably, but as testament to the filtration efficiency of the latest gasoline particulate filters (GPFs), tailpipe mass emissions are now as low as 0.02 mg/km. Gasoline vehicles were tested as they represent the majority of new passenger cars sold today. Therefore, the mass wear from new tires is 16 times greater than the maximum permitted from the tailpipe, but 3,650 times greater than actual tailpipe emissions. Taking the full-life average tire emissions, that premium falls to the 1,850 times mentioned earlier. The excess emissions under aggressive driving should alert us to a risk with BEVs: greater vehicle mass and torque delivered can lead to rapidly increasing tire particulate emissions. Half a tonne of battery weight can result in tire emissions that are almost 400 more times greater than real-world tailpipe emissions, everything else being equal. Nevertheless, it is important to say that a gentle BEV driver, with the benefit of regenerative braking, can more than cancel out the tire wear emissions from the additional weight of their vehicle, to achieve lower tire wear than an internal combustion engine vehicle driven badly.