How tyre emissions hide in plain sight

But it's not especially an electric vehicle problem

Emissions testing is usually preoccupied by testing for known, worrisome chemicals in the environment. Often they are in small amounts or concentrated at hotspots. Sophisticated equipment is deployed to find and measure them. We obsess with ever-tighter regulation of these pollutants we know about, even well beyond the point of diminishing environmental returns. At the same time, emissions from tyre wear from vehicles are all around us, and inside us, but we hardly see it. There is so much of it, and it is camouflaged by its chemical complexity, that we don’t notice. It is visible but unperceived. We urgently need to reprogramme our perceptive faculties to recognise the danger right in front of us.

Recent peer-reviewed scientific research estimated that a median adult excretes 11.8 nanograms per kilogram of bodyweight of 6PPD and 6PPD-quinone in urine per day. These chemicals have been made famous by ground-breaking research on the West Coast of the US, which linked them to mass fatalities of coho salmon – and more recently various types of trout. 6PPD is a preservative present in almost all tyres and few other products, which forms 6PPD-quinone when it reacts with oxygen in the air, and this is the chemical that kills the fish. We covered this in an earlier newsletter. Now, the data on human urine from South China, which is soon to be published, strongly suggests that when we emit, we pass tyre emissions.

Emissions Analytics has been testing for the rate of tyre wear emissions in real-world conditions over a number of years, across thousands of miles on many different types of tyre. The current average wear rate for a whole vehicle is 67 mg/km from new tyres, and this is predicted to halve over the tyres’ lifetime. Therefore, particulate mass generated from tyre wear is nearly 2,000 times greater than that from the tailpipe of modern ICE vehicles, as previously reported. In addition, our testing suggests for every 500 kg extra vehicle weight – about the mass of a large battery – tyre wear emissions rise by 21%. By some, this has been interpreted as an attack on BEVs, as they are heavier. While it is true that this comprehensively disproves the notion – bizarrely incorporated in legal statute in many countries – that BEVs are zero emission, a better interpretation is that all tyre emissions are high compared to the tailpipe particle mass from the latest ICE vehicles. To complete the picture, it should also be recognised that tyre and tailpipe emissions approach parity when the comparator is an older diesel vehicle with no particulate filter installed, or on a vehicle with a compromised filter.

Therefore, we should not call the tyre emissions issue exclusively a BEV problem. The trend towards heavier ICE sports utility vehicles has been a contributor to these growing emissions rates as well. In fact, having now tested over 300 different tyre models for their chemical composition from around the world, there is an emerging picture that specialist BEV tyres designed to handle the greater weight and torque of the vehicle may contain fewer potentially toxic compounds. So, the wear rates may well remain high if the driver is using the available torque, but in terms of environmental damage this may be offset by better formulations. This mitigation does tend to come at a higher purchase price, however. It does further mean that, if a BEV is equipped with non-specialist tyres – most likely when the owner replaces the original manufacturer tyres – the emissions could be higher in both wear and potential toxicity. We will present further results on these innovative formulations in a later newsletter.

This analysis makes it clear that tyre wear emissions are being generated when any of the world’s 1.5 billion cars are driven. Latest estimates suggest they shed about 6 million tonnes of tyre material per year, or 4 kg per car per year. It is often suggested, however, that this is not a big problem, because the particles shed tend to be larger and get caught in storm drains and filtered out, or sit harmlessly by the roadside. There are many reasons to doubt this. First, in many countries, the particles are filtered out from storm drains and road run-off, but the resulting sludge is then sold back to farmers for fertiliser. Another undesirable form of circular economy.

By our estimates, around 10% of the total tyre particulate matter is airborne – primarily the ultrafine particles – but a majority is often said to settle on the land. Recent peer-reviewed scientific research from Casten et al in Environmental Science & Technology studied the uptake, metabolism and accumulation of tyre wear particles and derived compounds in lettuce. It found that 6PPD and 6PPD-quinone – among other compounds – were “…readily taken up by lettuce…” via the roots and then translocated to the leaves in a way that “…may be of concern to consumers.” The paper describes how tyre wear particles may leach derivative compounds even before entering the soil, but that “…the majority of compounds are expected to be released once TWP [tyre wear particles] enter the agricultural soils and come in contact with soil pore water.” This provides a challenge to potential regulation to understand derivative chemicals and their toxicity, as well as the original particles.

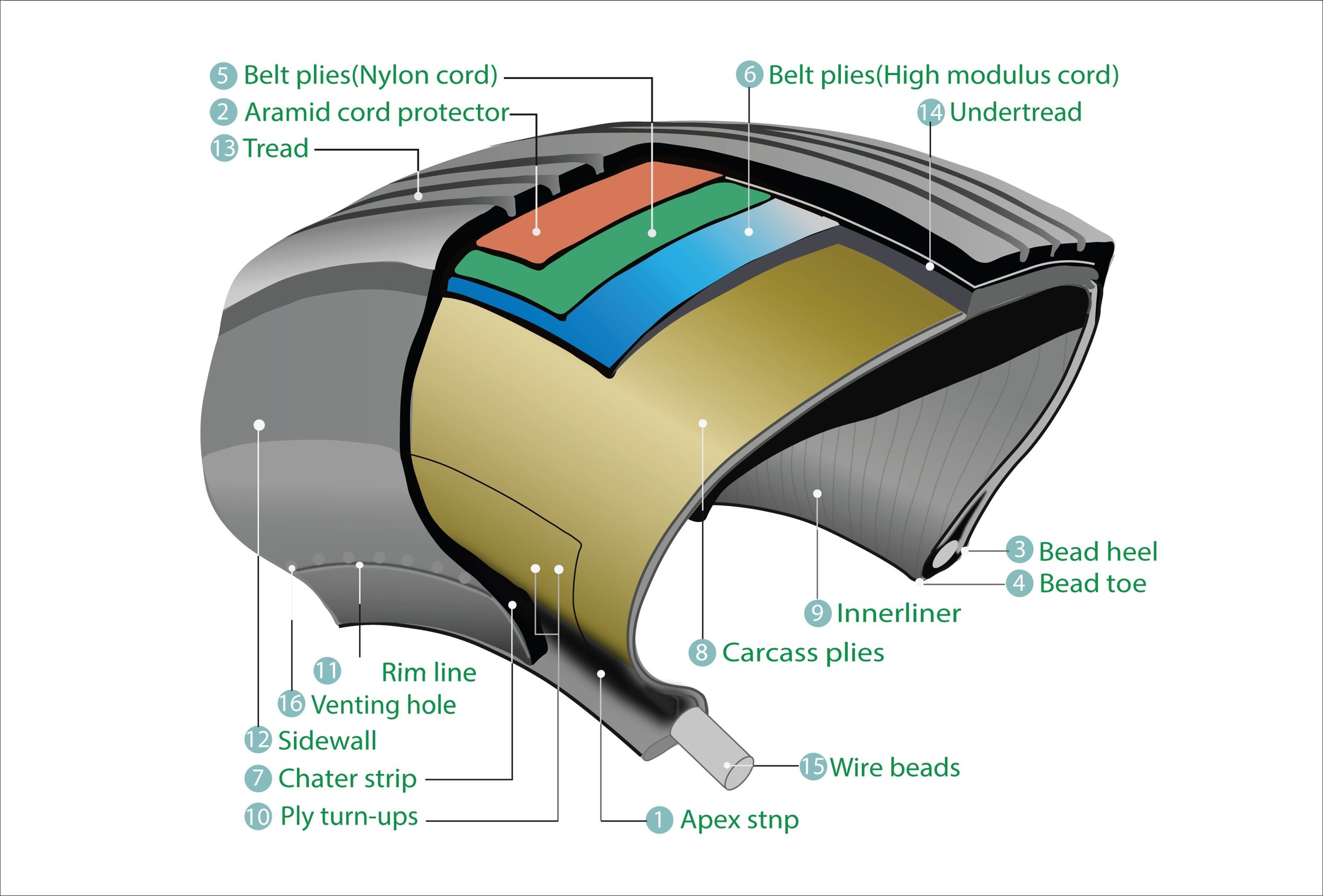

Fortunately, to aid this process, Emissions Analytics’ test programme aimed at mapping the chemical composition and leaching potential from tyre wear is progressing apace. Our subscription database has recently been expanded to add over one hundred tyre models from the US market – across light- and heavy-duty vehicles – to add to the hundreds of samples from the European market. The results help confirm one finding: that tyres are extremely complex and sophisticated in their construction. While this is impressive from an industrial and technology point of view, it helps create the problem set out at the start of this newsletter: the complexity helps camouflage their presence all around us in the environment.

To illustrate this, we took one high-selling tyre from a major European manufacturer and took samples from five different locations: inside and outside tread, the centre band around the middle circumference, and the inside and outside sidewalls. It was expected that the inside and outside tread composition should be similar, as only some performance tyres have asymmetric construction – this was indeed the case for the tyre tested. The centre band was expected to be different as it needs properties including conductivity, although the differences were relatively small and specific.

But what of the comparison between the outside tread and outside sidewall? The tread primarily has exposure to the physical stresses caused by driving, while the sidewall helps maintain the structural integrity while being exposed to sunlight much of the time. The chart below shows the 25 most prevalent organic compounds found – using our specialist two-dimensional gas chromatography and time-of-flight mass spectrometry method – plus 6PPD. The average number of compounds found was 350 per sample. The scale is in nanograms of compounds per milligram of tyre sample, expressed logarithmically. The coloured areas represent the tread and sidewall respectively.

This shows that the sidewall has higher concentrations of certain chemicals, not least androstan-17-one‚ 3-ethyl-3-hydroxy-‚ (5α)-, which is a chemical found naturally in nutgrass, and lends certain properties to the tyre. It is also higher in naphthalene‚ 1‚6‚7-trimethyl-, which is part of the naphthalene group and known to be harmful if swallowed and very toxic to aquatic life at certain concentrations, with potentially long-lasting effects. The tread has higher concentrations of other chemicals, for which many have little or no toxicological information available. An exception is 1‚1'-Biphenyl‚ 2-methyl-, which is a known skin irritant, can cause eye damage, and affect the respiratory tract. Perhaps surprising, the concentration of 6PPD was higher in the tread than the sidewall, despite the sidewall being more exposed to sunlight.

These chemicals are all important to understand, and they can affect the environment in multiple ways. The tyre gets abraded, and the resulting particles can get inhaled or ingested by humans. As they settle on soil they can enter the food chain, as can particles that enter the waterways and either end up as drinking water for humans or inside fish and other animals then eaten by humans. Chemicals on the surface of the tyre can also react with the air or other chemicals to produce derivative products with toxicological effects, as with 6PPD leading to 6PPD-quinone. Such reactions can also lead to the formation of secondary organic aerosols, i.e. more particles. All along, chemicals originally bound up in the tyre particles may leach out at different rates and with different effects.

We conclude from this that, while different parts of the tyre have different chemical compositions, reflecting their different roles, many of the compounds are common. We are now able to identify both these common compounds and the differentiating compounds, which makes possible wider, targeted environmental monitoring to understand the sources and ultimate fate of tyre emissions. It also opens up paths to reducing the environmental impact, such as the California Environmental Protection Agency’s proposed targeting of 6PPD, which will force tyre manufacturers to consider alternatives. It is the assessment of the properties of the alternatives which will be important, to ensure we don’t switch one problem for another.

So, as you drizzle your salad with some tasty, oily dressing, you now know that the lettuce itself may be carrying various compounds that originated from the crude oil used to make the tyres, that wore as you drove to work, and that settled on the neighbouring farmer’s field. These chemicals are all around us, and inside us.

At least, however, we now know what to look for and can measure them out in the real world. Their camouflage is blown.