What’s in a tyre?

This matters because tyres shed a lot of material into the environment.

What’s in a tyre?

Thousands of chemicals derived from crude oil, many of them volatile organic compounds, apparently.

This matters because tyres shed a lot of material into the environment. Emissions Analytics’ estimates suggest that around 300,000 tonnes of ‘rubber’ are released every year from passenger cars in Europe and US alone, the equivalent of over forty million brand new, entire tyres. These particles go into the air, soil and watercourses. If you were to stack all the tyres manufactured in the world in a year on their side, it would reach the moon.

While there is a tyre labelling scheme in the EU, it only rates rolling resistance, wet grip and noise. These are clearly vital to the performance and safety of tyres, but it leaves the ratings blind to the environmental consequences of the tyre wear emissions. There are restrictions on toxic chemicals that can be included in the manufacture of tyres under the European REACH regulations, but the number of chemicals affected is limited.

While we have been occupied with reducing exhaust emissions to control air quality problems, other sources of pollutants have not received the same attention historically. Now that tailpipe emissions of modern internal combustion engines (ICEs) in both Europe and US are generally well below regulated limits for pollutants, focus is now turning to ‘non-exhaust emissions’, which cover tyres. Emissions Analytics’ testing shows that, in normal driving, tyre wear emissions are about one hundred times greater than tailpipe particle mass on a modern ICE vehicle. In legal but extreme driving, enough to reduce significantly the lifespan of a vehicle’s tyres, that factor increases to around one thousand.

In addition to tyres, non-exhaust emissions cover material from brake and road wear, as well as resuspended solids, whipped up from the carriageway by the moving vehicle. Of these, tyre wear emissions are probably the largest and fastest-growing component. Brake wear emissions are forecast to fall as regenerative braking becomes more widespread. Road wear and resuspension rates are only partly related to the passing vehicle, including its weight, but are probably more determined by the road material and condition, and what particles are blown onto the road from multiple surrounding sources. Tyre wear emissions are likely to grow as vehicles continue the long-term trend of becoming heavier, although this may at some point be offset by using more lightweight construction materials.

Understanding tyre wear emissions provides a challenge as they are heterogenous. Unlike, for example, nitrogen oxide (NOx), which is a unique compound that can be measured as a mass or volume, particles from tyres come in an infinite combination of shapes, sizes and densities. Moreover, the particles are made up of a wide array of chemical compounds, and these chemicals may also stick – or adsorb – to the surface of the particle. In this way, particles can act as the distribution vector for other compounds.

An emerging approach to characterising tyre wear emissions is, therefore, to measure both the wear rates and chemical make-up of the particles. This enables a quantification of the amount of individual chemicals that are released into the environment. This information can then be put together with toxicity ratings to assess the potential effect on human health, wildlife and biodiversity. For the semi-volatile organic compounds particularly, the effect of these on secondary organic aerosol formation – in other words, gaseous emissions that condense to become airborne particles over time – can be evaluated.

To begin to understand the degree and nature of the tyre wear emissions problem, Emissions Analytics recently tested a range of different tyres. Full sets of tyres of eight different brands and types were selected and installed on the same test vehicle, a 2012 rear-wheel drive Mercedes C-Class. The wheel alignment and tyre pressures were checked. Each set of tyres was driven for over 1,000 miles, around 90% by distance being conducted on the motorway. The four wheels – i.e. leaving the tyres on the rims to avoid damage – were weighed at the start and end, and the distance-specific loss of mass was calculated. The results are shown in the chart below.

Across the brands, the average mass loss was 64mg/km for the vehicle, adding all four tyres together. Wear on the rear tyres was greater, accounting for 71% of the total on average, strongly influenced by this being a rear-wheel drive car. The wear rate on the fastest abrading tyre was 2.3 times higher than the slowest. Therefore, tyre choice by manufacturers and consumers can have a material impact on emissions rates.

The wear rate is faster when tyres are new, for the first few thousand miles. Thereafter, the wear rate appears to decline at an approximately logarithmic rate. Over a lifetime, therefore, the average wear rate may be half the figures above. If we assume that the average vehicle travels around 16,000km per year, the rates above mean that each car sheds around 0.5kg per year on average over its lifetime. As there are almost 600 million vehicles in Europe and the US, this is equivalent to 300,000 tonnes of particles. An average tyre weights around 8kg, hence the total amount shed is equivalent to almost 40 million whole tyres. These figures do not include tyre wear from heavy-duty vehicles, which would also be significant.

The effect of particles on human health and the wider environment is an on-going and active area of research. It is complex to isolate the causal links. In terms of air pollution, it is generally accepted that there is a connection between particle mass emissions and diseases such as cancer and heart disease from prolonged exposure. The effects in terms of particle number are less clear-cut, although the EU regulates these at the tailpipe from a precautionary motive. The aim of this newsletter is not to review the evidence, but rather to contribute early findings on the chemical composition of tyres studied so far by Emissions Analytics.

Tyres are highly-engineered products and made up of a complex mixture of substances. For light-duty vehicles, the majority of the content of the tyre tread and walls comes from crude oil derivatives, with only a minority of natural rubber. Therefore, to understand the composition of tyres, it is necessary to employ a technique that can separate these out. We decided to focus on the organic compounds rather than metals, and employed our two-dimensional gas chromatography equipment coupled with a time-of-flight mass spectrometer (GCxGC-TOF-MS from SepSolve Analytical and Markes International, see https://www.emissionsanalytics.com/tyre-emissions). The gas chromatograph achieves separation by passing a sample through a long ‘column’, and the mass spectrometer does the compound identification. Two dimensions, both of time, are required to separate compounds that ‘elute’ in the same place in a one-dimensional chromatogram. Taking an example tyre, we heated samples to 100˚C and analysed the compounds released to obtain the following two-dimensional chromatogram.

Broadly, compounds cluster in different areas depending on common chemical characteristics. Some frequently used groups are illustrated above. Alkanes (e.g. pentane) typically affect the lungs, liver, kidney and brain. Cycloalkanes (e.g. cyclohexane) lead to headaches and dizziness. Terpenes (e.g. limonene) are generally less problematic and are responsible for aromas, unlike aromatics (e.g. benzo(a)pyrene), which are often carcinogens, as are nitrogen-containing compounds (e.g. quinoline). This is a significant simplification for the purposes of illustration.

Each shaded area on the chromatogram indicates a distinct chemical, with the intensity of the colour reflecting its abundance. The measurement breadth of the equipment is from compounds containing two carbon atoms (C₂) to at least C44. This covers what are called volatile organic compounds (VOCs) and semi-volatile organic compounds (SVOCs). Just this one sample contains well over a thousand distinct compounds of these types.

The next stage is to identify as many of the compounds as possible and understand if they are problematic for health or the environment. Zooming in on the nitrogen-containing part of the chromatogram, it is possible to identify a number of potentially problematic compounds, as shown below.

N-Phenyl pyrrole, quinazoline, 4-tert-butyl-2-chlorophenol at certain levels of exposure can lead to symptoms in humans including skin, eye and respiratory irritation. In addition to these effects, quinoline and 3-methyl-quinoline have potential carcinogenicity and mutagenicity in humans. Quinoline and 1,2-dihydro-2,2,4-trimethyl affect aquatic environments more than humans.

This suggests that potentially concerning compounds are present in tyres, but if we compare the composition of different tyre brands it is also possible to see that the mix of chemicals differs. This reflects the many formulations used by different producers, but also means that tyre selection can lead to different environmental and health effects. The chart below illustrates the point by comparing four different tyre types. Each sample was pyrolysed to release as many compounds in the underlying materials as possible, and then analysed using Principal Component Analysis.

Tyre Brand B is strongly differentiated from the other three tyres by the presence of 1-methyl-2-pentyl-cyclohexane – a cycloalkane. Although it does not have any particular toxic indications for humans, it is potentially possible to relate the presence of this defining compound to other characteristics such as rolling resistance, noise or wet grip.

Where toxic compounds are identified by this approach, it does not guarantee that they are present in amounts that could cause harm. Therefore, the final stage is to quantify each in the sample, so the total amount in a tyre can be worked out. However, even if the amounts are small in one tyre, due to the large amount of material released each year in total – as calculated above – even low concentrations could lead to deleterious effects at the macro level.

All in all, this initial testing has demonstrated that it is possible to measure tyre wear explicitly, without it being combined with brake or road wear, and the separation capability of the two-dimensional gas chromatograph can help identify thousands of constituent compounds. The results themselves then show that there are relevant and material differences in the wear rates and chemical make-up of different brands and models of tyre. Therefore, choices of tyre when the car is first sold and at subsequent tyre changes are directly relevant to the vehicle’s environmental impact, and requires deeper and urgent study.

What else is coming out of our tailpipes?

Tightening tailpipe regulations is a natural impulse in a post-Dieselgate world. However, we are in danger of over-regulating familiar, easy-to-measure emissions such as CO2 and NOx while ignoring a wide range of other, potentially harmful substances that can now be measured but have previously been ignored.

Unregulated volatile organic compounds

Tightening tailpipe regulations is a natural impulse in a post-Dieselgate world. However, we are in danger of over-regulating familiar, easy-to-measure emissions such as CO2 and NOx while ignoring a wide range of other, potentially harmful substances that can now be measured but have previously been ignored.

As European legislators move beyond the Euro 6 tailpipe emissions standard, they are beginning to grapple with this, at the same time that non-tailpipe emissions are rapidly coming into focus as a major concern.

Previous newsletters focused on two types of non-exhaust emissions – tyre wear and vehicle interior air quality focusing on volatile organic compounds (VOCs) produced by the car’s own interior. Today we turn back to tailpipe emissions but with the same mindset – what substances are emitted but not regulated, and are they harmful?

For tailpipe VOCs, some laboratory regulations exist around the world, but only on a limited basis, and averaged over a test cycle. Here, we look at real-time data we gathered with Cambridge, UK-based Anatune, which show a richer picture and some unexpected results.

In the previous newsletter on VOCs (https://bit.ly/2xyzyZa) we showed that it is possible to identify different analytes in real time, measure the rate at which they are emitted and reveal unexpected spikes in some analytes that surpassed regulated limits.

Turning to tailpipe emissions, we worked with Anatune again to use the SIFT-MS to sample the tailpipes of a 2011 model-year Volkswagen Golf (diesel); a 2019 model-year Peugeot 2008 (gasoline) and a 2019 model-year Renault Captur (diesel). The cars were soaked in a controlled environment prior to testing. During the first 100 seconds the probe, positioned in the tailpipe, measured the prevailing ambient air; From 100-400 seconds ignition and idle; from 400-800 seconds at 1,500 rpm; from 800-1,100 seconds at 3,000 rpm and then back to idle for the last 100 seconds.

We conducted the analysis for hydrocarbons, sulphurs and oxygenates. Hydrocarbons are the product of combustion and include butadiene, heptane, styrene, benzene, hexane, toluene, butane, methane and xylenes + ethylbenzene.

Anatune Senior Application Chemist and SIFT-MS Specialist Dr Mark Perkins notes that they all have a degree of toxicity and are all regulated in respect of occupational exposure limits (OEL). Heptane is a marker for unburnt fuel.

The outstanding result of the test is the unanticipated initial spike in heptane and other hydro-carbons xylenes + ethylbenzene, methane, styrene and toluene, observed in the only petrol vehicle we tested, the Peugeot.

In particular, the spike in heptane in the first few seconds after ignition reached a concentration of over 6,000 micrograms per cubic metre. This was sixty times more than the highest reading for the older diesel Golf, while the Renault never produced more than 25 micrograms of heptane.

The peak heptane production occurred differently in both diesel vehicles, at the 800 second juncture when engine revolutions were doubled from 1,500 to 3,000.

The newer, diesel Renault had very low emissions of all hydrocarbons except for an initial peak of methane upon ignition, of 200 μg/m3; the older VW had a peak methane emission of 80 μg/m3, while butane emissions tracked methane emissions and styrene rose and fell proportionately to engine load.

Moving on to sulphurs, which include ammonia, carbonyl sulphide, dimethyl sulphide and hydrogen sulphide, we observed a sudden spike at 750 seconds from a baseline of nil to over 400 μg/m3 of ammonia, again for the gasoline-powered Peugeot. We can only assume here that there was a ‘burp’ from the catalytic converter which was momentarily overwhelmed, but there is no clear or definite explanation.

Once again the overwhelming thing to note is the scale of the gasoline car’s emissions compared to the diesels’. The average ammonia emissions from the Peugeot at 3,000 rpm are over 50 μg/m3, compared to a maximum of 0.6 μg/m3 in the Renault and 0.4 μg/m3 in the VW.

Moving on to oxygenates, these are volatile organic compounds such as methacrolein, acetone, butanal, butanone, ethanol, hexanal and methanol.

The important thing to remember about these VOCs is that they may not be toxic in isolation, and in tiny amounts. But they are not being emitted in isolation and have a direct impact on broader categories of pollution.

Under sunlight, VOCs react with vehicle-emitted nitrogen oxides to form ozone, which in turn helps the formation of fine particulates. The accumulation of ozone, fine particulates and other gaseous pollutants results in smog.

The VW Golf produced methacrolein at over 6 μg/m3 when the engine was stepped up to 3,000 rpm. Exposure to methacrolein is highly irritating to the eyes, nose, throat and lungs. The VW also produced just below 5 μg/m3 of acetone, less toxic than methacrolein but causing irritation to eyes and throat.

The Renault also produced noticeable amounts of acetone, peaking at almost 6 μg/m3, but never breached 3 μg/m3 for methacrolein.

The gasoline Peugeot offered a completely different map. Mirroring the hydro-carbon results, it shows a spike on first ignition in hexanal to nearly 140 μg/m3, and between 4-500 seconds two spikes in butanal of 80 and 50 μg/m3 respectively. Butanal (N-butyraldehyde) is an organic compound which is the aldehyde derivative of butane. It is judged to be of low toxicity to humans unless inhaled at high concentrations, causing chronic headaches and ataxia.

By way of summary, many of the observed measurements followed the dynamic that any vehicle engineer would anticipate. Immediately following a step-up in rpm there is a spike in emissions before a steep fall. This represents the time gap between more fuel being sent to combust and control mechanisms responding, upon which a new equilibrium is reached.

But the take-away result here is the very high emissions of some hydrocarbons and other VOCs from the gasoline-engined Peugeot upon ignition from cold. Heptane, a marker for unburned fuel, spiked momentarily to over 6,000 μg/m3, almost 60 times the highest level observed throughout the test from the older diesel, the Volkswagen.

Similar spikes are seen from methane, xylenes and ethylbenzene, hexane and styrene – all measured in quantities 10-40 times higher than the two diesels.

Using the SIFT-MS approach has shown that beneath the more familiar time-weighted average of total emissions, whether of VOCs or hydrocarbons, is a dynamic and unexpectedly ‘spiky’ reality that can result in rapid accumulations of some chemicals well above their permissible, regulated maximums.

Fueling the Future podcast: Tires Not Tailpipe

Our Founder & CEO Nick Molden was delighted to be invited onto the Fueling The Future podcast to take part in a discussion with Tammy Klein of Future Fuel Strategies about non-exhaust emissions in vehicles.

Our Founder & CEO Nick Molden was delighted to be invited onto the Fueling The Future podcast to take part in a discussion with Tammy Klein of Future Fuel Strategies about non-exhaust emissions in vehicles.

Click below to hear the podcast:

You can also subscribe to the Fueling The Future podcast on iTunes by clicking here.

Press Release: Pollution From Tyre Wear 1,000 Times Worse Than Exhaust Emissions

Pollution from tyre wear can be 1,000 times worse than what comes out of a car’s exhaust, Emissions Analytics has found.

Tight regulation of exhaust emissions by the EU has meant that new cars emit very little particle pollution

But tyre wear pollution is unregulated and can be 1,000 times worse, finds independent real-world testing experts Emissions Analytics

Increased popularity of SUVs, larger and heavier than standard vehicles, exacerbates this problem – as does growing sales of heavy EVs and widespread use of budget tyres

Fitting only high-quality tyres and lowering vehicle weight are routes to reducing these ‘non-exhaust emissions’

Oxford, 6th March 2020: Pollution from tyre wear can be 1,000 times worse than what comes out of a car’s exhaust, Emissions Analytics has found.

Harmful particle matter from tyres – and also brakes – is a very serious and growing environmental problem, one that is being exacerbated by the increasing popularity of large, heavy vehicles such as SUVs, and growing demand for electric vehicles, which are heavier than standard cars because of their batteries.

What’s more, vehicle tyre wear pollution is completely unregulated, unlike exhaust emissions which have been rapidly reduced by car makers thanks to the pressure placed on them by European emissions standards. New cars now emit very little in the way of particulate matter but there is growing concern around ‘non-exhaust emissions’.

Non-exhaust emissions (NEE) are particles released into the air from brake wear, tyre wear, road surface wear and resuspension of road dust during on-road vehicle usage. No legislation is in place to limit or reduce NEE, but they cause a great deal of concern for air quality.

NEEs are currently believed to constitute the majority of primary particulate matter from road transport, 60 percent of PM2.5 and 73 percent of PM10 – and in its 2019 report ‘Non-Exhaust Emissions from Road Traffic’ by the UK Government’s Air Quality Expert Group (AQEG), it recommended that NEE are immediately recognised as a source of ambient concentrations of airborne particulate matter, even for vehicles with zero exhaust emissions of particles – such as EVs.

To understand the scale of the problem, Emissions Analytics – the leading independent global testing and data specialist for the scientific measurement of realworld emissions – performed some initial tyre wear testing. Using a popular family hatchback running on brand new, correctly inflated tyres, we found that the car emitted 5.8 grams per kilometer of particles.

Compared with regulated exhaust emission limits of 4.5 milligrams per kilometer, the completely unregulated tyre wear emission is higher by a factor of over 1,000. Emissions Analytics notes that this could be even higher if the vehicle had tyres which were underinflated, or the road surfaces used for the test were rougher, or the tyres used were from a budget range – all very recognisable scenarios in ‘real world’ motoring.

Richard Lofthouse, Senior Researcher at Emissions Analytics said: “It’s time to consider not just what comes out of a car’s exhaust pipe but particle pollution from tyre and brake wear. Our initial tests reveal that there can be a shocking amount of particle pollution from tyres – 1,000 times worse than emissions from a car’s exhaust.

“What is even more frightening is that while exhaust emissions have been tightly regulated for many years, tyre wear is totally unregulated – and with the increasing growth in sales of heavier SUVs and battery-powered electric cars, non-exhaust emissions (NEE) are a very serious problem.”

Nick Molden, CEO of Emissions Analytics said: “The challenge to the industry and regulators is an almost complete black hole of consumer information, undone by frankly out of date regulations still preoccupied with exhaust emissions. In the short term, fitting higher quality tyres is one way to reduce these NEEs and to always have tyres inflated to the correct level.

“Ultimately, though, the car industry may have to find ways to reduce vehicle weight too. What is without doubt on the horizon is much-needed regulation to combat this problem. Whether that leads to specific types of low emission, harder wearing tyres is not for us to say – but change has to come.”

ENDS

Media contact

For all media inquiries please contact Sam Hardy on +44 (0)7815 863968, or via media@emissionsanalytics.com

About Emissions Analytics

Emissions Analytics is the leading independent global testing and data specialist for the scientific measurement of real-world emissions and fuel efficiency for passenger and commercial vehicles and non-road mobile machinery. Emissions Analytics seeks to bring transparency to a confused market sector. It publishes the EQUA Index of real-world driving emissions, and works with clients around the world to establish accurate emissions measurement and data requirements.

Tyres Not Tailpipe

Why low tailpipe particle emissions may now be dominated by tyre wear.

Why low tailpipe particle emissions may now be dominated by tyre wear.

When you think of vehicle emissions, you naturally think of the exhaust pipe. Think again.

The newest internal combustion engine vehicles are achieving pollutant emission levels so low they are hard to measure. Yes, significant carbon dioxide still comes from the exhaust, but this does not affect urban air quality.

Arguably the biggest source of pollutant emissions from new vehicles now comes from non-exhaust sources, especially brake and tyre wear. This newsletter concentrates on the latter, as tyres are likely to be a large and growing source as consumers switch to bigger and heavier cars. Research shows they contribute to microplastic marine pollution, as well as air pollution from finer particles.

And this source of pollution is currently unregulated.

The 2019 report Non-Exhaust Emissions from Road Traffic by the UK Government’s Air Quality Expert Group (AQEG) recommends “…as an immediate priority that non-exhaust emissions (NEEs) are recognised as a source of ambient concentrations of airborne PM, even for vehicles with zero exhaust emissions of particles.”

Non-exhaust emissions include physical road wear particles from vehicles eroding the surface, the re-suspension of existing particles lying on the carriageway, brake wear particles and tyre wear particles. Greater adoption of regenerative braking means that brake wear emissions may decrease. However, thanks to the high weight and poor aerodynamics of sport utility vehicles (SUVs) as well as the high weight and torque drive characteristics of battery electric cars (BEVs), tyre emissions are expected to increase. In the light of this, we have begun a broad tyre testing programme at Emissions Analytics.

Complementing this is our traditional expertise in exhaust emissions, which for the purpose of this newsletter will focus on diesel exhaust particulates and some further reflections on the particle emissions of gasoline engines.

Declining tailpipe emissions from diesels

If we tackle diesel vehicles first, the truth is that they have emitted very few particles, at least in relative terms, since the broad introduction of diesel particulate filters a decade ago. So long as this filter has not malfunctioned or been tampered with, emissions are low over typical driving cycles, even taking into account the significantly elevated levels during the periodic ‘regeneration’ of the filter where the accumulated particles are burned off.

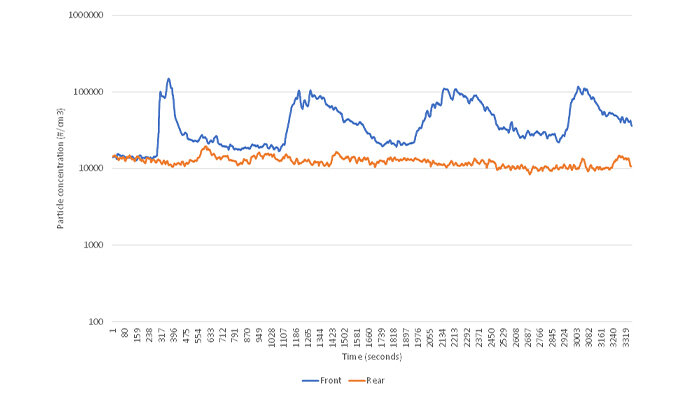

Filters are so good that we have measured that in certain circumstances, when the ambient air is already polluted, a diesel car will tend to extract more particles from the air than it emits. Emissions Analytics worked with the leading European automotive publisher, Auto Motor und Sport, to test four recent models of diesel cars.

Considering one of the vehicles, a canister of high intensity particles was opened in front of the air intake on four occasions across 60 minutes while the car idled. Upon the canister being opened, the particle number soared tenfold in the ambient air, but the corresponding exhaust count remained largely flat throughout the hour, with even a slightly declining trend.

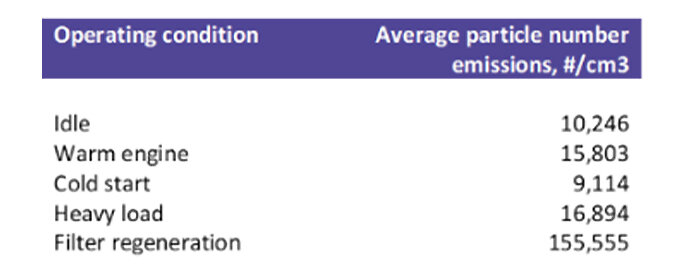

Then we ran on-road tests across the four vehicles, measuring exhaust particles from cold start, at neutral idle, with a warmed-up engine, under heavy load and finally during the filter-regeneration process. The test data was then analysed into illustrative trips of 300, 30 and 3 kilometres to simulate highway, commuting and local errand duty cycles:

Long Distance: 300km, average 60km/h, idling 10%, warm engine 70%, cold start 5%, heavy load 10%, filter regeneration 5%

Middle Distance: 30km, idling 10%, warm engine 40%, cold start 20%, heavy load 10%, filter regeneration 20%

Short Drive: 3km, cold start 100%.

The average per-second tailpipe emissions in the various operating modes across the four vehicles were:

The standout result, which we did not anticipate, is that the net contribution of each car to particle pollution rests primarily on the ambient air, reflecting the dynamic way in which a car ingests air as well as exhausts it.

On a polluted day where ambient concentrations of particles are already high at 50,000 #/cm3, the vehicles remove on average 27,984 particles per second of operation. Conversely, on a clean air day when ambient concentrations are 10,000 #/cm3, all four vehicles are net polluters but at low levels in relative terms, averaging emissions of 12,016 particles per second of operation. This was across the 300km drive cycle.

During the 30km, middle-distance test with filter regeneration, all four cars are net polluters except on the dirtiest days for two of the vehicles. The latter detail is an important measure of the still relatively low absolute levels of particle emissions, albeit higher by a factor of 10 compared to normal operation.

For the ‘short errand’ 3km drive, the filters work exceptionally well. A completely cold particle filter is not inhibited, unlike SCR systems, which are highly sensitive to operating temperatures. On the ‘short errand’ route two of the vehicles were ‘net cleaners’ even on a ‘clean air’ day.

Note: negative figures indicate net cleaning of the air, and are marked in green.

Note that we are here making no comment about nitrogen oxides (and other gaseous) emissions from diesel vehicles, or the stark reality in many cities of a considerable stock of older, non-filtered diesels that are often very high particle emitters.

Recognising therefore that we have only tested one element of the overall diesel equation, nonetheless these tests raise important questions for the industry at a pivotal moment in drivetrains. To broaden the analysis, we must also consider gasoline particulate emissions, which have risen steeply as port-injection engines have been replaced by direct injection engines in an attempt to reduce CO2 emissions. This technology, which has been around since at least 2007, has become the norm rather than the exception.

Gasoline particulate emissions

In contrast to Port Fuel Injection (PFI) engines, Gasoline Direct Injection (GDI) engines have higher compression ratios and lower charge temperatures, delivering various efficiencies including lower fuel consumption. However, they are also responsible for increased fine and ultrafine particle emissions1. From our testing, the average PN emissions from GDI engines are more than five times higher than PFI engines: 1.3 x 1011 #/km compared to 0.3 x 1011 #/km respectively, both under warm start.

This matters hugely, given that in the four years that have followed the start of the VW ‘Dieselgate’ scandal in September 2015, diesel registrations across Europe have fallen from a peak market share of 51% in 2015 to below 30% by the end of the third quarter of 2019, according to the European Car Makers Association, ACEA. Simultaneously, there has been a shift in the complexion of gasoline engines towards GDIs, which now make up approximately half of the market.

While the balance of non-diesel sales has fallen to alternative fuel, hybrid and electric vehicles, and gasoline cars, 3rd Quarter sales in Europe in 2019 showed gasoline cars still outselling full battery electric cars by 29:1. Gasoline now accounts for 59.5% of the European market, while all the other alternative, non-diesel categories (electric, hybrid, mild hybrid and natural gas) only amount to 11.3% 2 .

The subject of gasoline exhaust emissions is a complex one, and under Euro 5b (since September 2011) the European limit of 4.5 mg/km PM (mass) and 6.0 x 1011 #/km PN (number) has resulted in some but not all gasoline models being fitted with particulate filters. We should note that the nature of particles emitted by diesel vehicles and gasoline vehicles is slightly different. In general particles from GDI engines, while high in number are really quite small – and indeed it’s looking likely that EU legislation will move from 23nm diameter to 10nm to take this into account. Diesel particles are of the order of 100nm. These sizes are still tiny compared to the more familiar PM2.5 and PM10, which refers to micrometre values. PM10 represents the coarser particles around one-tenth the width of a human hair – 10 micrometres is equal to 10,000nm. Even the often referred to “fine particles” of PM2.5 can be up to 2,500nm in size.

If we are correct about this, there has been a sharp increase in potentially dangerous ultrafine particles as a consequence of the widespread adoption of direct injection gasoline engines plus a market swing back to gasoline. This increase in ultrafines has only recently been policed with the introduction of the Real Driving Emissions regulation.

Comparison to tyre wear emissions

While this has been going on, tyres have not been regulated at all for their emissions, and are believed to have become a leading source of non-exhaust emissions and of broad concern whether considered as an airborne source of pollution or as a watershed microplastic. Non-exhaust emissions are believed to constitute today the majority source of primary PM from road transport, 60% of PM2.5 and 73% of PM10 [DEFRA, 2019].

How to explain these figures, which seem inexplicably high?

In our initial tyre testing we began with a basic mass loss approach, hypothesising that an average tyre might shed an estimated 1.5kgs over a 30,000km life. In respect of the 200-mile (320km) test we conducted, this equates 16g in mass loss over that distance. Quadrupling the figure to account for four tyres, and dividing by 320 gives a theoretical per km mass loss of 0.2g (200 milligrams), already 44 times more mass loss per kilometre than is permitted in the current exhaust regulation (4.5 mg/km).

To our surprise, in real-world testing we found that tyre wear can be much, much higher than our starting hypothesis – as shown in our previous newsletter. As we were originally concerned that the mass loss levels would be too small to measure, we stacked the decks by choosing the cheapest tyres, ballasted the car heavily, chose a track with average surface quality and designed a test cycle with high speeds and much cornering.

Driving a 2011 VW Golf 320kms at high road speeds on the track resulted in a mass loss of 1,844g which equates 5.8g per km. This was 29 times worse than our hypothesis, and partly explained by our deliberate quest for a ‘worst case scenario’. It should be noted that the driving and vehicle payload would be aggressive but legal if conducted on the public highway.

Nevertheless, it is a very high figure: 5,760mg/km of completely unregulated tyre wear emission versus regulated exhaust emission limits of 4.5mg/km – a factor of over 1,000. And while we sought a worst-case scenario it could have been worse still. As safety organisations repeatedly note the real ‘real world’ is one in which tyres are routinely underinflated, increasing wear, whereas ours were inflated exactly to their correct levels; rough surfaces abound in many countries; speed limits are broken and budget tyres have flooded the market for years.

One objection to this may be that this lost tyre mass is mostly large particles which fall rapidly to the ground, whereas the tailpipe emissions are mostly ultrafines that hang in the air. It is true that most of the tyre mass was at the top end of the measured size range (PM10 or up to 10,000nm), and the tailpipe particles are mostly below 100nm. However, the tyre wear emissions also included a high number of particles down to 10nm, as a result of volatilisation of the tyre material due to heat in the tyres. Therefore, tyres shed material that both leads to microplastics in the watercourse, and ultrafines that compromise air quality.

Future trends

As the UK’s AQEG notes, that while regenerative braking is expected to reduce brake wear emissions, the increased weight and inefficiency of SUVs and battery electric vehicles will likely be associated with increased tyre wear, road wear and resuspension. The AQEG also goes further in speculating that a possible technological mitigation method for reducing tyre emissions would be ‘mandating formulation of low-wear/low-emission tyres, brake pads and road surfaces.’

We think it will go much further than that. New problems prompt new solutions, some of which are already at hand. There is a world of difference between high quality tyres and low quality tyres, for one thing; and the persistent bias of the industry currently towards aggressively-tyred high performance BEVs is partly an effort to market them to a still sceptical public, a trend that will moderate as BEVs become more accepted and efficiency rises to the surface. Driver style and the extent to which power electronics can moderate torque delivery is another evolving dynamic.

The challenge to the industry and regulators is an almost complete black hole of consumer information undone by frankly out of date regulations still preoccupied with exhaust emissions.

This flies in the face of current trends towards heavy SUV-bodied BEVs sporting traditionally wide, low profile tyres, compared to a much tinier subsection of BEVs in the marketplace that prize efficiency and refinement over looks and ultimate performance.

For now, tyre emissions are a wholly unregulated aspect of motoring, but we greatly doubt that this will remain the case. If tyres are shedding even a fraction of 5.8 g/km we have measured, and more than 1,000 times tailpipe emissions, this subject must be taken seriously.

1 Raza, Mohsin, Longfei Chen, Felix Leach and Shiting Ding. A Review of Particulate Number (PN) Emissions from Gasoline Direct Injection (GDI) Engines and Their Control Techniques. Energies 2018, 11, 1417: p1.

2 2,120,988 gasoline cars were sold across Europe in the third quarter of 2019, compared to 73,137 battery electric vehicles – 29x more. Figures from ACEA.

Burning Issue: Tyres And Air Quality

Are tyres replacing tailpipe as the policy priority?

Are tyres replacing tailpipe as the policy priority?

Tyres are rapidly emerging as a new source of environmental concern and this will affect the car industry.

In a recently aired BBC radio documentary, it was claimed that the world will discard 3 billion tyres in 2019, enough to fill a large football stadium 130 times1. Beyond this broad issue of resource use and material waste, tyres also sit uniquely at the intersection of air quality and microplastics.

This newsletter sketches the problem in its current form and considers certain automotive developments in its light.

As a car drives by, you cannot see its tyres wearing and therefore ‘tyre wear’ in this sense remains imperceptible except in deliberately extreme use such as branches of motor sport such as drag racing and drifting.

Yet over a lifetime of between 20-50,000kms, a tyre will shed approximately 10-30% of its tread rubber into the environment, at least 1-2kgs2. The wear factor (defined as the total amount of material lost per kilometre) varies enormously depending on tyre characteristics such as size – radius/width/depth – tread depth, construction, pressure and temperature. In one recent Emissions Analytics’ test, conducted under real-world rather than lab conditions, the four tyres on a standard hatchback lost 1.8kg over just 200 miles of fast road speeds, far in excess of what had been anticipated by the testers.

A tyre abraids owing to the friction between its contact patch and the road surface. It ‘emits’ particles across a broad size spectrum, from coarse to fine to ultrafine to nanoscale. It may also emit other forms of aromatics such as benzopyrene and benzofluorene, the result of the incomplete combustion of organic matter resulting in evaporation of the volatile content of the tyres, which the EU has regulated to a degree3.

Coarse particles typically fall rapidly to the ground. At the fine level and smaller, they are airborne for a certain duration, either being blown away from the carriageway before settling on the ground, or falling to the carriageway where re-suspension may take place as other vehicles pass.

Particle dispersion and deposition eventually occurs, but that is not the end of the story. The particles typically pass into the watershed through street drainage and are estimated to be a primary source of as much as 28% of microplastics found in the marine environment4.

The recent re-characterisation of tyre wear emissions as ‘microplastic pollution’ corrects the broadly misleading public idea, out of date a hundred years and counting, that tyres are composed principally of natural rubber. Instead, tyres are a close derivative of crude oil and their wholesale pricing typically tracks it.

A typical car tyre comprises 45% oil-derived synthetic rubber (polymer), 40% oil-derived carbon-black (filler, 40%), and 15% various additives to aid production processes, some of which typically contain heavy metals and some of which are also oil-derived.

Some tyres contain natural rubber, but to all intents and purposes we live in the age of the plastic tyre.

For not unrelated reasons, we also live in the age of the disposable tyre. From being an expensive product derived in large part from natural rubber, tyres have fallen in cost as globalisation has catapulted numerous new entrant tyre-makers into what is today a $240bn a year industry.

If we now turn to the automotive world, tyres are more important than ever to vehicle attractiveness and performance, but for many different reasons:

An emphasis on vehicle and tyre performance is often at the price of tyre longevity, particularly where higher diameter wheel rim sizes are combined with wide tyres, whether to convey power or sportiness

Tyres have become more disposable as their price has fallen in real terms, replacing an older tradition of re-treading carcasses for extended life

New entrant tyre-makers in Asia, South Asia and Eastern Europe have led to the advent of the ‘budget tyre’

Electric vehicles offer instant torque and higher kerb weights, implying higher tyre wear rates, even while regenerative braking is expected to reduce brake wear emissions

Electrification leads to a completely new appraisal of the tyre in respect of durability and noise

In-cabin tyre noise becomes a high-concern consumer issue as drivetrain noise is reduced or eliminated.

From a regulatory viewpoint, tyres in Europe are labelled according to three criteria, (the so-called ‘performance triangle’): rolling resistance, wet grip and noise – but that may change as tyre environmental impact rises up the political agenda.

From our perspective, Emissions Analytics has been conducting in-depth real-world tests on tyres. Two immediate insights can be shared:

Budget tyres wear rapidly and have high emissions

New instrumentation capable of measuring emissions down to the nanoscale shows that at the ultrafine level and smaller, the particle mass becomes far less instructive than the particle number, which is much more significant, and yet current regulations only measure mass

The size distribution has potential implications for the epidemiology (health) concern around very fine particulate matter and how it may affect human health.

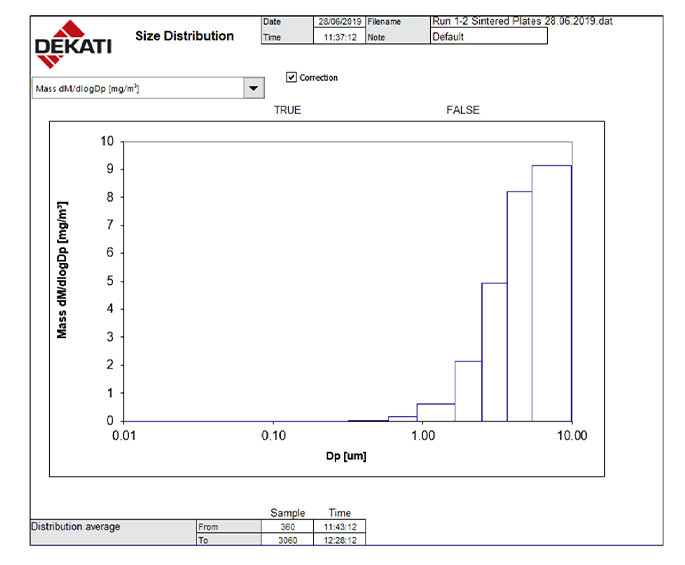

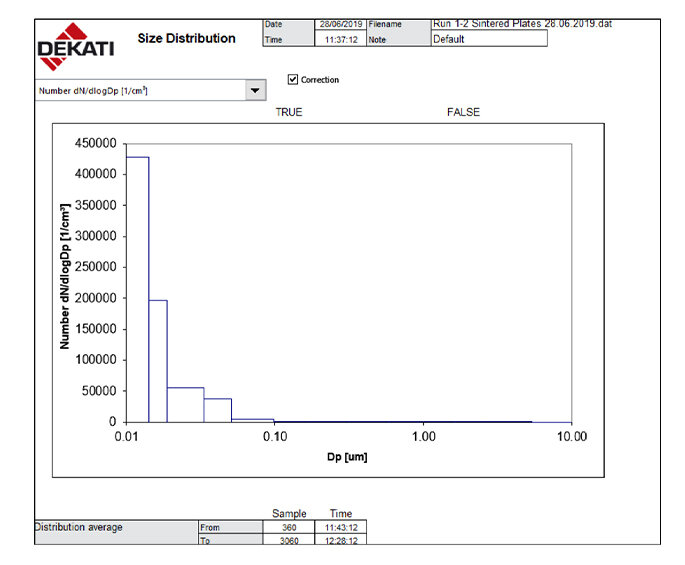

In one recent test, Emissions Analytics used a Dekati ELPI+ (Dekati® ELPI®+ Unit standard with 14 size fractions from 6nm up to 10um for PN/PM concentration at 1Hz/10Hz sampling rate) to measure both particle mass and number. The first chart below shows the resulting mass distribution.

We regard this as a valuable piece of data even though it only corroborates what is broadly known, that a comparatively small number of coarser particles (up to and including the 10 micrometre size shown in the far right column, familiar as PM10) account for most of the recorded mass.

Then consider however the contrast when particle number is accounted for rather than mass: you get a mirror of the first graph, with a tiny amount of mass expressed as a very high number of nanoscale particles right down to the 10-nanometre level expressed in the first column (0.01 micro-metre).

This is a potentially valuable insight because until now this high particle number count has typically either not been measurable or not been measured, owing to a regulatory preoccupation with mass and a lack of suitably sensitive real-time measurement instrumentation.

The ability to count particles down to 10 nanometres relies on the quality of the impactor chosen for this test, which is considered to be the best currently available on a commercial basis.

Regarding public health, there is a tentative emerging consensus among epidemiologists and other medical researchers that ultra-fine particles are potentially more injurious to human health than coarse particles, owing to their ability to translocate to the bloodstream through the lungs5.

Particles will need to continue to be measured both for their mass and their number. In respect of mass they are emitted in a large size range by tyres. In respect of number they emitted in high volumes.

We highlight the UK government’s recent report Non-Exhaust Emissions from Road Traffic, authored by the UK Government’s Air Quality Expert Group (AQEG). It recommends “as an immediate priority that non-exhaust emissions (NEEs) are recognised as a source of ambient concentrations of airborne PM, even for vehicles with zero exhaust emissions of particles.”

Quite apart from the broader point here that so-called ‘zero emission vehicles’ are in fact significant sources of non-exhaust emissions, the quantity of such emissions is set to rise.

The same UK government report notes that non-exhaust emissions are believed to constitute today the majority source of primary particulate matter from road transport, 60% of PM2.5 and 73% of PM10. While regenerative braking is expected to reduce brake wear emissions, the increased weight and torque characteristics of alternative drivetrains such as EVs will likely be associated with increased tyre wear.

In the same report it is suggested that a 10kg increase in vehicle mass accounts for a 0.8-1.8% increase in nanoparticle emissions from tyres. This is particularly relevant as a whole generation of new EVs is hitting the roads with considerably larger and heavier battery packs than in the past.

For small to medium cars, where modest range is acceptable for city use or where the glider (bare chassis) has been deliberately lightweighted to offset batteries (as per the BMW i3), the weight gain may be marginal. Indeed, a switch to narrow tyres may neutralise or even reduce tyre wear.

But a Tesla Model S or Model X, Mercedes EQC, Audi e-tron or Jaguar i-Pace, EVs with larger ranges and battery packs in the range of 60-100 kWh, weigh 2.3-2.6 tonnes. The 600kg battery pack in the Mercedes EQC would on the AQEG/DEFRA model potentially increase nanoparticle emissions from tyres by 48-108%, compared to a conventional vehicle weighing 600kg less.

The same argument can be extended to internal combustion engine vehicles. A heavier vehicle increases tyre wear, whereas lightweighting mitigates it. This has implications for the broader market trend towards SUVs, where often particularly large rim tyre sizes are adopted.

On this basis we think tyres are set to be scrutinised and regulated more, and perhaps also reinvented for electric cars to perform well in durability and noise. There will be opportunities and threats that arise from these changes.

We anticipate the need to place a value on low emission tyres, so that they are desired and consumers are willing to pay for them, in other words using a tax policy that internalises the externality to the benefit both of society and the environment.

1 Costing the Earth: Tread Lightly. BBC Radio 4, March 13th, 2019.

2 Grigoratos & Martini, 2014.

3 Since 2010 the EU has required the discontinuation of the use of extender oils which contain more than 1 mg kg−1 Benzo(a)pyrene, or more than 10 mg kg−1 of the sum of all listed polycyclic aromatic hydrocarbons in the manufacture procedure due to increased health concerns related to PAHs (European Commission, 2005).

4 Microplastics are considered to be all plastic particles in the range of 0.1–5,000 µm. A secondary source is when a larger plastic object breaks down once already in a marine environment. The figure of 28.3% was originally cited in Julien Boucher, Damien Friot, Primary Microplastics in the Oceans: a Global Evaluation of Sources, International Union for Conservation of Nature and Natural Resources, 2017, p21.

5 Newby, David: ‘Air Pollution and Cardiovascular Disease - A Mills and Boon Classic’ (2019).

Archive

- AIR Alliance 3

- Air Quality 38

- Audio 3

- Climate Change 14

- EQUA Index 21

- Electrified Vehicles 28

- Euro 7 3

- Fuel Consumption/Economy 20

- Fuels 4

- Infographic 18

- Media 4

- NRMM/Off-road 3

- Newsletter 103

- Podcast 7

- Presentation/Webinar 18

- Press Release 19

- Regulation 16

- Reports 4

- Tailpipe Emissions 49

- Tyre Consortium 2

- Tyre Emissions 26

- Vehicle Interior 6